- Home Page

- Company Profile

-

Our Products

- CHEMICAL HARDENER

- CHEQUERED TILES MOULD

- COLOR MIXING MACHINE

- CONCRETE BLOCK MOULDS

- HEXAGON KIDA MOULD

- Double Zigzag Mould

- GRASS GRID MOULD

- Milano Paver Block Moulds

- GRASS PAVER MOULD

- L-SHAPE MOULD

- Kaju Katli Paving Block Mould

- MATKA MOULD

- Kida Brooks Mould

- Interlocking Concrete Block Moulds

- Interlocking Paver Moulds

- Mould For Paver Block

- Interlock Block Moulds

- New Damru Mould

- New Cosmic Mould

- CONCRETE CHEMICAL

- CONCRETE HARDENER

- CONCRETE MIXER

- COVER BLOCK MOULDS

- Round Cover Block Mould

- 64 Cavity Pvc Cover Block Mould

- 20,25,30mm 64 Cavity Cover Block Mould

- Multy Cavity Cover Block Mould

- Cover Block Rubber Moulds

- RUBBER COVER BLOCK MOULD

- Square Cover Block Mould

- Concrete Cover Block Moulds

- Cover Block Mould In 20, 25, 40, 50.mm

- 42 Cavity Pvc Cover Block Mould

- Rcc Cover Block Mould

- Cover Block Moulds

- Pvc Cover Block Mould

- Cover Block Moulds Manufacture

- SPACERS RUBBER MOULD

- 49 Cavity Rubber Cover Block Mould

- Cover Block Mould Supplier

- Cover Block Mould 20 & 25.mm

- DESIGNER TILES MOULD

- FLOOR TILES MOULD

- HARDENER MAKING MACHINE

- Paver Block Hardener Making Machine

- Concrete Block Hardener Making Machine

- Hardener Machine

- Interlocking Hardener Machinery

- Interlocking Tile Hardener Making Machine

- Block Hardener Making Machine

- Chemical Hardener Making Machine

- Concrete Hardener Making Machine

- Cover Block Hardener Making Machine

- Designer Tile Hardener Making Machine

- Hardener Making Machine

- Interlocking Block Hardener Making Machine

- Paver Block Clean Mould Releasing Chemical Making Machine

- Paver Chemical Hardener Making Machine

- Paver Hardener Machinery

- Paving Block Hardener Machine

- Rmc Admixtures Chemical Making Machine

- Tile Hardener Chemical Making Machine

- Tile Hardener Making Machine

- CONCRETE ADMIXTURE MAKING MACHINE

- CHEQUERED TILE HARDENER MAKING MACHINE

- INTERLOCKING BLOCK MAKING MACHINE

- INTERLOCKING TILE MAKING MACHINE

- IRON OXIDE PIGMENT

- KERB STONE MOULDS

- LACQUER POLISH MAKING MACHINE

- Interlocking Block Lacquer Polish Making Machine

- Floor Paint And Floor Coat Making Machine

- Paving Block Lacquer Polish Making Machine

- Interlocking Tile Lacquer Polish Making Machine

- Paver Lacquer Making Machine

- Chequered Tiles High Gloss Lacquer Coating Making Machine

- Designer Tile Lacquer Polish Making Machine

- Lacquer Coating Making Machine

- Lacquer Polish Machine

- Lacquer Polish Making Machine

- Lacquer Sealer Making Machine

- Lacquer Shiner Making Machine

- Paver Block High Gloss Lacquer Polish Making Machine

- Paver Block Lacquer Polish Making Machine

- Tile Coating Machine

- Tile Lacquer Polish Making Machine

- Top Coat Lacquer Making Machine

- Water Base Lacquer Coating Making Machine

- Block Lacquer Polish Making Machine

- Water Proofing Coating Making Machine

- MANUAL BLOCK MAKING MACHINE

- PAVER BLOCK DEMOULDING MACHINE

- PAVER BLOCK HARDENER

- PAVER BLOCK LACQUER POLISH

- LACQUER COATING FOR PAVER BLOCKS

- TILE LACQUER POLISH

- HIGH GLOSS LACQUER COATING

- ACRYLIC COATINGS

- ACRYLIC LACQUER

- TOP COAT PAVER BLOCK LACQUER

- PAVER BLOCK SHINER

- TILE POLISH

- LACQUER PAINTS

- LIQUID POLISH FOR PAVING BRICKS

- PAVER BLOCK LACQUER COATING

- WATER PROOFING COATING CHEMICAL

- PAVER SEALER

- PAVER COATING LACQUER

- LACQUER COATING

- PAVER LACQUER

- LACQUER POLISH FOR PAVER BLOCKS

- INTERLOCKING TILES POLISH

- LACQUER POLISH

- PAVER BLOCK LACQUER

- LACQUER COLOR COATING CHEMICAL

- HIGH GLOSS LACQUER POLISH

- INTERLOCKING TILE LACQUER POLISH

- PAVER BLOCK PAINT

- NATURAL LACQUER POLISH

- FLOOR PAINT SPECIAL IN PAVER BLOCK & CHEQUERED TILE

- FLOOR PAINT FOR CHEQUERED TILE

- COLOR COATING FOR PAVER BLOCK

- PAVER BLOCK MACHINERY

- PAVER BLOCK MAKING MACHINE

- PAVING BLOCK MOULDS

- SOUTH SET MOULD

- PRECAST PAVER MOULDS

- SILICONE PAVER MOULDS

- ZIG ZAG PAVER MOULD

- V-SHAPE MOULD

- S-SHAPE MOULD

- PAVER BLOCK FARMA

- STAR MOULD

- PAVING BRICK MOULDS

- TRIHEX MOULD

- NEW HEXAGON MOULD

- PAVER BLOCK MOULD

- SQUARE PAVER MOULDS

- PISTON MOULD

- PAVING BLOCK MOULDS

- PAVER MOULDS

- Cement Concrete Tile Lacquer polish making machine

- PVC MOULDS

- PVC PAVER MOULDS

- Pan Mixer Machine

- Color Pan Mixer Machine

- Heavy Duty Pan Mixer Machine

- Paver Block Pan Mixer Machine

- Interlocking Tile Pan Mixer

- PAN MIXER

- Top Layer Pan Mixer

- Top Color Layer Pan Mixer

- Ring Pan Mixer

- Color Pan Mixer

- Paver Block Pan Mixer

- Pan Mixer Machine

- Pan Mixer Machine For Interlocking Tile

- Ring Pan Mixer Machine

- Top Layer Pan Mixer Machine

- RUBBER MOULDS PAVER

- SUPERPLASTICIZER ADMIXTURE

- TILE HARDENER

- TILE MAKING MACHINE

- VIBRATING TABLE

- Designer Vibro Forming

- Heavy Duty Vibro Forming Table

- Paver Designer Tiles Vibro Forming Table

- Vibrator Machine For Paver Block

- Construction Vibro Forming Machine

- Interlocking Block Vibro Forming Machine

- Designer Tile Vibro Forming Table

- Concrete Block Vibro Forming Table

- Designer Tiles Vibro Forming Table

- Interlocking Tile Vibro Forming Machine

- Paver Block Vibro Forming Machine

- VIBRO FORMING MACHINE

- Construction Vibrating Table

- Interlock Vibrating Machine

- HEAVY DUTY VIBRO FORMING TABLE

- PAVER TILE VIBRATING TABLE

- Paver Block Vibrating Table

- Vibro Forming Machine

- Vibro Forming Table Standard

- Tile Vibro Forming Machine

- Vibrating Table Concrete Moulds

- Vibro Table Paver Block Making Machine

- VIBRATING TABLE FOR CONCRETE

- VIBRO FORMING TABLE

- Contact Us

Tile Banane Wali Machine

Price 160000 INR/ Piece

MOQ : 1 Piece

Tile Banane Wali Machine Specification

- Product Type

- TILE MAKING MACHINE

- General Use

- Industrial

- Method

- Semi-Automatic

- Processing

- Hydraulic Press

- Automatic

- Semi-Automatic

- Power

- 2 HP 3 PHASE Horsepower (HP)

- Voltage

- 220-240 Volt (v)

- Capacity

- 1000-1500 tiles/day

- Weight (kg)

- Approx 850 kg

- Warranty

- 1 YEAR

- Brick Raw Material

- Cement, Sand, Fly Ash, Pigment

- Type

- Paver Block / Tile Making

- Dimension (L*W*H)

- 1500 mm x 800 mm x 1700 mm

- Color

- Blue / Yellow (As per availability)

- Mould Type

- Interchangeable Moulds

- Application

- Manufacturing of Interlocking Tiles, Chequered Tiles, Designer Tiles, Paver Blocks

- Cycle Time

- 15-20 seconds per batch

- Operator Required

- 1

- Material of Construction

- Mild Steel Body

- Vibration Motor

- Yes, Heavy Duty

- Oil Tank Capacity

- 80 Litres

- Surface Finish

- Smooth

Tile Banane Wali Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 4-5 Days

- Main Domestic Market

- All India

About Tile Banane Wali Machine

Tile Banane Wali Machine

Js Designer Tiles Product Is A Leading Manufacturer Of Synthetic Silicone Plastic Mould, Synthetic Silicone Rubber Mold, Paver Block Making Machine, Spray Lacquer Polish, Sponge Lacquer Polish, Iron Oxide Etc.

Efficient and Versatile Tile Production

Engineered to deliver high output and superior surface finishes, the Tile Banane Wali Machine supports the manufacturing of various tiles, including interlocking and chequered types. Its robust mild steel frame ensures durability, while interchangeable moulds provide maximum flexibility for different tile designs.

Optimized Hydraulic and Vibration Systems

Featuring a combination of hydraulic press and vibration motor technology, this machine produces tiles with precise shapes and smooth surfaces every cycle. The large oil tank maintains steady hydraulic pressure, allowing consistent, repeatable performance, ideal for industrial tile production.

Designed for Operator Simplicity and Safety

Only one operator is required to manage the production process, which is facilitated by a user-friendly, semi-automatic control panel. Safety guidelines and maintenance support are included, ensuring both ease of use and peace of mind with a comprehensive 1-year warranty.

FAQs of Tile Banane Wali Machine:

Q: How does the Tile Banane Wali Machine operate for tile manufacturing?

A: The machine operates on a semi-automatic hydraulic press mechanism. One operator loads the raw materialscement, sand, fly ash, and pigmentinto the mould, and the machine uses hydraulic pressure and vibration to shape tiles with a smooth surface finish in just 15-20 seconds per cycle.Q: What type of tiles can be produced with this machine?

A: It is designed for the production of interlocking tiles, chequered tiles, designer tiles, and paver blocks. Thanks to interchangeable moulds, various shapes and designs can be easily achieved, accommodating most common industrial tile requirements.Q: When is the ideal application for this machine in the manufacturing process?

A: The Tile Banane Wali Machine is best used in medium to large-scale industrial settings where a high volume of tilesapproximately 1000-1500 per dayis required. Its efficiency in cycle time and flexibility with moulds make it suitable for daily production processes.Q: Where can this machine be installed?

A: It can be installed in manufacturing plants, construction material workshops, or any facility with adequate power supply (220-240V, 3-phase) and space (machine dimensions: 1500mm x 800mm x 1700mm). The robust construction allows it to operate reliably in various industrial environments across India.Q: What is the process for changing the tile moulds?

A: Moulds can be interchanged easily by pausing the machine, unlocking the current mould assembly, and securing a new mould in place. This process allows seamless transition between different tile styles, enhancing production flexibility.Q: How does the machines vibration motor enhance tile quality?

A: The vibration motor ensures that the mixture settles evenly within the mould during pressing, eliminating air gaps and resulting in a uniformly smooth surface finish on every tile produced.Q: What are the primary benefits of using this machine for tile manufacturing?

A: Key benefits include high output efficiency, versatile mould compatibility, superior surface finish, simple operation requiring only one operator, and durable construction with a 1-year warranty for peace of mind.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in TILE MAKING MACHINE Category

TILE MACHINE MANUFACTURER

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, SemiAutomatic

General Use : Industrial

Product Type : TILE MAKING MACHINE

Power : 2 HP 3 PHASE Horsepower (HP)

Interlocking Brick Machine

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, Semi Automatic

General Use : Industrial

Product Type : TILE MAKING MACHINE

Power : 2 HP 3 PHASE Horsepower (HP)

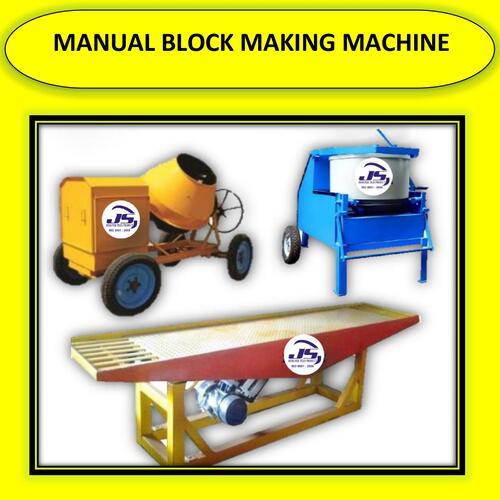

Manual Block Making Machine

Price 160000 INR / Plant

Minimum Order Quantity : 1 Plant

Automatic : No

General Use : Industrial

Product Type : TILE MAKING MACHINE

Power : 2 HP 3 PHASE Horsepower (HP)

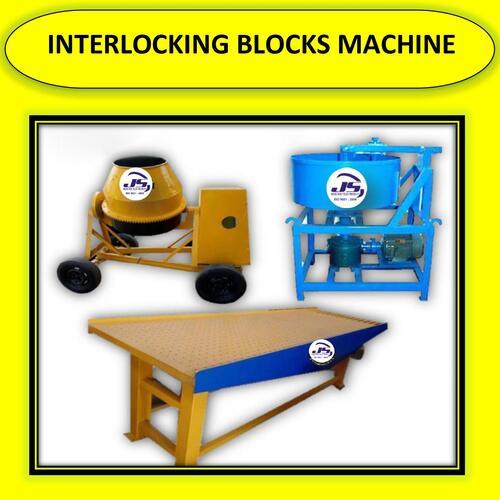

Interlocking Blocks Machine

Price 160000 INR / Piece

Minimum Order Quantity : 1 Pole

Automatic : No

General Use : Industrial

Product Type : TILE MAKING MACHINE

Power : 2 HP 3 PHASE Horsepower (HP)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free