- Home Page

- Company Profile

-

Our Products

- CHEMICAL HARDENER

- CHEQUERED TILES MOULD

- COLOR MIXING MACHINE

- CONCRETE BLOCK MOULDS

- HEXAGON KIDA MOULD

- Double Zigzag Mould

- GRASS GRID MOULD

- Milano Paver Block Moulds

- GRASS PAVER MOULD

- L-SHAPE MOULD

- Kaju Katli Paving Block Mould

- MATKA MOULD

- Kida Brooks Mould

- Interlocking Concrete Block Moulds

- Interlocking Paver Moulds

- Mould For Paver Block

- Interlock Block Moulds

- New Damru Mould

- New Cosmic Mould

- CONCRETE CHEMICAL

- CONCRETE HARDENER

- CONCRETE MIXER

- COVER BLOCK MOULDS

- Square Cover Block Mould

- Multy Cavity Cover Block Mould

- 42 Cavity Pvc Cover Block Mould

- Cover Block Rubber Moulds

- Rcc Cover Block Mould

- Pvc Cover Block Mould

- Cover Block Moulds

- Cover Block Mould 20 & 25.mm

- Concrete Cover Block Moulds

- Cover Block Mould In 20, 25, 40, 50.mm

- 49 Cavity Rubber Cover Block Mould

- Cover Block Moulds Manufacture

- SPACERS RUBBER MOULD

- Round Cover Block Mould

- RUBBER COVER BLOCK MOULD

- Cover Block Mould Supplier

- 20,25,30mm 64 Cavity Cover Block Mould

- 64 Cavity Pvc Cover Block Mould

- DESIGNER TILES MOULD

- FLOOR TILES MOULD

- HARDENER MAKING MACHINE

- Paver Block Hardener Making Machine

- Concrete Block Hardener Making Machine

- Hardener Machine

- Interlocking Hardener Machinery

- Interlocking Tile Hardener Making Machine

- Block Hardener Making Machine

- Chemical Hardener Making Machine

- Concrete Hardener Making Machine

- Cover Block Hardener Making Machine

- Designer Tile Hardener Making Machine

- Hardener Making Machine

- Interlocking Block Hardener Making Machine

- Paver Block Clean Mould Releasing Chemical Making Machine

- Paver Chemical Hardener Making Machine

- Paver Hardener Machinery

- Paving Block Hardener Machine

- Rmc Admixtures Chemical Making Machine

- Tile Hardener Chemical Making Machine

- Tile Hardener Making Machine

- CONCRETE ADMIXTURE MAKING MACHINE

- CHEQUERED TILE HARDENER MAKING MACHINE

- INTERLOCKING BLOCK MAKING MACHINE

- INTERLOCKING TILE MAKING MACHINE

- IRON OXIDE PIGMENT

- KERB STONE MOULDS

- LACQUER POLISH MAKING MACHINE

- Interlocking Block Lacquer Polish Making Machine

- Floor Paint And Floor Coat Making Machine

- Paving Block Lacquer Polish Making Machine

- Interlocking Tile Lacquer Polish Making Machine

- Paver Lacquer Making Machine

- Chequered Tiles High Gloss Lacquer Coating Making Machine

- Designer Tile Lacquer Polish Making Machine

- Lacquer Coating Making Machine

- Lacquer Polish Machine

- Lacquer Polish Making Machine

- Lacquer Sealer Making Machine

- Lacquer Shiner Making Machine

- Paver Block High Gloss Lacquer Polish Making Machine

- Paver Block Lacquer Polish Making Machine

- Tile Coating Machine

- Tile Lacquer Polish Making Machine

- Top Coat Lacquer Making Machine

- Water Base Lacquer Coating Making Machine

- Block Lacquer Polish Making Machine

- Water Proofing Coating Making Machine

- MANUAL BLOCK MAKING MACHINE

- PAVER BLOCK DEMOULDING MACHINE

- PAVER BLOCK HARDENER

- PAVER BLOCK LACQUER POLISH

- ACRYLIC COATINGS

- TILE LACQUER POLISH

- HIGH GLOSS LACQUER COATING

- LACQUER COATING FOR PAVER BLOCKS

- PAVER BLOCK SHINER

- TOP COAT PAVER BLOCK LACQUER

- ACRYLIC LACQUER

- TILE POLISH

- LACQUER PAINTS

- LIQUID POLISH FOR PAVING BRICKS

- PAVER SEALER

- PAVER BLOCK LACQUER COATING

- WATER PROOFING COATING CHEMICAL

- PAVER COATING LACQUER

- LACQUER COATING

- PAVER LACQUER

- LACQUER POLISH FOR PAVER BLOCKS

- INTERLOCKING TILES POLISH

- LACQUER POLISH

- LACQUER COLOR COATING CHEMICAL

- PAVER BLOCK LACQUER

- HIGH GLOSS LACQUER POLISH

- INTERLOCKING TILE LACQUER POLISH

- PAVER BLOCK PAINT

- NATURAL LACQUER POLISH

- FLOOR PAINT SPECIAL IN PAVER BLOCK & CHEQUERED TILE

- FLOOR PAINT FOR CHEQUERED TILE

- COLOR COATING FOR PAVER BLOCK

- PAVER BLOCK MACHINERY

- PAVER BLOCK MAKING MACHINE

- PAVING BLOCK MOULDS

- SOUTH SET MOULD

- SILICONE PAVER MOULDS

- ZIG ZAG PAVER MOULD

- V-SHAPE MOULD

- PRECAST PAVER MOULDS

- PAVER BLOCK FARMA

- STAR MOULD

- PAVING BRICK MOULDS

- TRIHEX MOULD

- NEW HEXAGON MOULD

- PAVER BLOCK MOULD

- SQUARE PAVER MOULDS

- PISTON MOULD

- PAVING BLOCK MOULDS

- PAVER MOULDS

- S-SHAPE MOULD

- Cement Concrete Tile Lacquer polish making machine

- PVC MOULDS

- PVC PAVER MOULDS

- Pan Mixer Machine

- Heavy Duty Pan Mixer Machine

- Color Pan Mixer Machine

- Paver Block Pan Mixer Machine

- Interlocking Tile Pan Mixer

- PAN MIXER

- Top Layer Pan Mixer

- Top Color Layer Pan Mixer

- Ring Pan Mixer

- Color Pan Mixer

- Paver Block Pan Mixer

- Pan Mixer Machine

- Pan Mixer Machine For Interlocking Tile

- Ring Pan Mixer Machine

- Top Layer Pan Mixer Machine

- RUBBER MOULDS PAVER

- SUPERPLASTICIZER ADMIXTURE

- TILE HARDENER

- TILE MAKING MACHINE

- VIBRATING TABLE

- Paver Designer Tiles Vibro Forming Table

- Vibrator Machine For Paver Block

- Heavy Duty Vibro Forming Table

- Interlocking Block Vibro Forming Machine

- Construction Vibro Forming Machine

- Designer Vibro Forming

- Designer Tile Vibro Forming Table

- Concrete Block Vibro Forming Table

- Designer Tiles Vibro Forming Table

- Interlocking Tile Vibro Forming Machine

- Paver Block Vibro Forming Machine

- VIBRO FORMING MACHINE

- Paver Block Vibrating Table

- PAVER TILE VIBRATING TABLE

- Interlock Vibrating Machine

- HEAVY DUTY VIBRO FORMING TABLE

- Construction Vibrating Table

- Vibro Forming Machine

- Vibro Forming Table Standard

- Tile Vibro Forming Machine

- Vibrating Table Concrete Moulds

- Vibro Table Paver Block Making Machine

- VIBRATING TABLE FOR CONCRETE

- VIBRO FORMING TABLE

- Contact Us

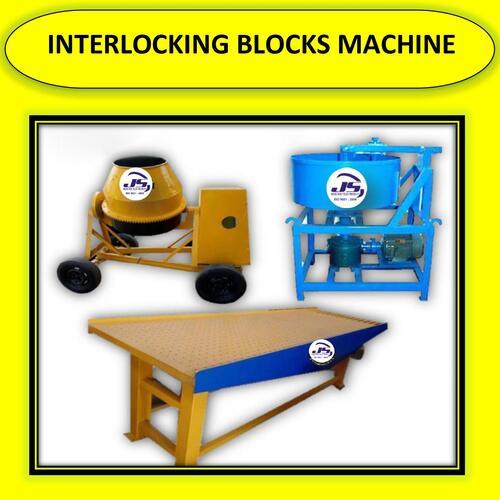

Interlocking Blocks Machine

Price 160000 INR/ Piece

MOQ : 1 Pole

Interlocking Blocks Machine Specification

- Product Type

- TILE MAKING MACHINE

- General Use

- Industrial

- Automatic

- No

- Power

- 2 HP 3 PHASE Horsepower (HP)

- Voltage

- 220-240 Volt (v)

- Warranty

- 1 YEAR

Interlocking Blocks Machine Trade Information

- Minimum Order Quantity

- 1 Pole

- Supply Ability

- 10 Poles Per Week

- Delivery Time

- 4-5 Days

- Main Domestic Market

- All India

About Interlocking Blocks Machine

Interlocking Blocks Machine

Js Designer Tiles Product Is A Leading Manufacturer Of Synthetic Silicone Plastic Mould, Synthetic Silicone Rubber Mold, Paver Block Making Machine, Spray Lacquer Polish, Sponge Lacquer Polish, Iron Oxide Etc.

Product details

|

Minimum Order Quantity |

1 Set |

|

Brand/Make |

JS |

|

Automation Grade |

Manual |

|

Capacity (Blocks per hour) |

375 |

|

Method |

Vibration |

|

Block Type |

Interlock |

|

Condition |

New |

Efficient Block Production

This Interlocking Blocks Machine is engineered for industrial applications, ensuring that block production is both consistent and efficient. With a powerful 2 HP 3-phase motor, it delivers reliable performance for continuous operations, making it ideal for businesses aiming to meet high-volume demands.

Simple and Reliable Operation

Though the machine is not automatic, its manual operation allows for easy control and minimal maintenance. The intuitive process reduces the need for specialized training, which helps operators produce interlocking blocks with consistent quality in a straightforward manner.

Trusted Manufacturer and Exporter

Manufactured in India, our machine is tailored for international and domestic clients. With a 1-year warranty and robust after-sales support, we ensure lasting value for exporters, manufacturers, and suppliers looking for durability and service excellence.

FAQs of Interlocking Blocks Machine:

Q: How does the Interlocking Blocks Machine operate?

A: The machine functions manually and requires an operator to feed raw materials into the mold and operate the controls. It utilizes a 2 HP, 3-phase motor to compress materials, ensuring sturdy and uniform interlocking blocks with each cycle.Q: What types of blocks can be produced with this machine?

A: It is specially designed for creating durable interlocking blocks used in construction, paving, and landscaping. The machine can handle various raw materials and produce blocks of different shapes and sizes based on the mold selected.Q: When should I schedule regular maintenance for the machine?

A: Routine maintenance is recommended after every significant production cycle or as specified in the user manual. Regular servicing ensures optimal performance, minimizes downtime, and extends the machines lifespan.Q: Where is this Interlocking Blocks Machine manufactured and shipped from?

A: The machine is manufactured in India and can be shipped both domestically and internationally to fulfill orders from various regions, thanks to robust export capabilities.Q: What is the process for installing and starting up the machine?

A: Installation requires access to a 220-240V, 3-phase power supply and a stable platform. Once connected, operators can follow the step-by-step user guide to begin producing blocks after a brief setup and calibration.Q: How is this machine beneficial for manufacturers and suppliers?

A: By offering reliable manual operation and industrial-grade construction, the machine reduces energy costs, requires minimal maintenance, and delivers consistency, making it a cost-effective solution for high-volume production environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in TILE MAKING MACHINE Category

Interlocking Brick Machine

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, Semi Automatic

Power : 2 HP 3 PHASE Horsepower (HP)

Warranty : 1 YEAR

General Use : Industrial

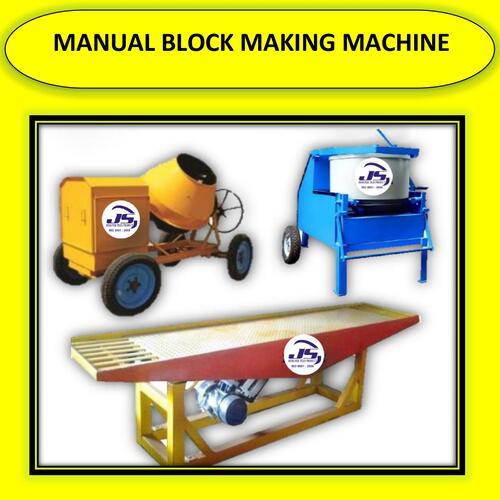

Manual Block Making Machine

Price 160000 INR / Plant

Minimum Order Quantity : 1 Plant

Automatic : No

Power : 2 HP 3 PHASE Horsepower (HP)

Warranty : 1 YEAR

General Use : Industrial

TILE MACHINE MANUFACTURER

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, SemiAutomatic

Power : 2 HP 3 PHASE Horsepower (HP)

Warranty : 1 YEAR

General Use : Industrial

Tile Banane Wali Machine

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, SemiAutomatic

Power : 2 HP 3 PHASE Horsepower (HP)

Warranty : 1 YEAR

General Use : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free