- Home Page

- Company Profile

-

Our Products

- CHEMICAL HARDENER

- CHEQUERED TILES MOULD

- COLOR MIXING MACHINE

- CONCRETE BLOCK MOULDS

- HEXAGON KIDA MOULD

- Double Zigzag Mould

- GRASS GRID MOULD

- Milano Paver Block Moulds

- GRASS PAVER MOULD

- L-SHAPE MOULD

- Kaju Katli Paving Block Mould

- MATKA MOULD

- Kida Brooks Mould

- Interlocking Concrete Block Moulds

- Interlocking Paver Moulds

- Mould For Paver Block

- Interlock Block Moulds

- New Damru Mould

- New Cosmic Mould

- CONCRETE CHEMICAL

- CONCRETE HARDENER

- CONCRETE MIXER

- COVER BLOCK MOULDS

- Round Cover Block Mould

- 64 Cavity Pvc Cover Block Mould

- 20,25,30mm 64 Cavity Cover Block Mould

- Multy Cavity Cover Block Mould

- Cover Block Rubber Moulds

- RUBBER COVER BLOCK MOULD

- Square Cover Block Mould

- Concrete Cover Block Moulds

- Cover Block Mould In 20, 25, 40, 50.mm

- 42 Cavity Pvc Cover Block Mould

- Rcc Cover Block Mould

- Cover Block Moulds

- Pvc Cover Block Mould

- Cover Block Moulds Manufacture

- SPACERS RUBBER MOULD

- 49 Cavity Rubber Cover Block Mould

- Cover Block Mould Supplier

- Cover Block Mould 20 & 25.mm

- DESIGNER TILES MOULD

- FLOOR TILES MOULD

- HARDENER MAKING MACHINE

- Paver Block Hardener Making Machine

- Concrete Block Hardener Making Machine

- Hardener Machine

- Interlocking Hardener Machinery

- Interlocking Tile Hardener Making Machine

- Block Hardener Making Machine

- Chemical Hardener Making Machine

- Concrete Hardener Making Machine

- Cover Block Hardener Making Machine

- Designer Tile Hardener Making Machine

- Hardener Making Machine

- Interlocking Block Hardener Making Machine

- Paver Block Clean Mould Releasing Chemical Making Machine

- Paver Chemical Hardener Making Machine

- Paver Hardener Machinery

- Paving Block Hardener Machine

- Rmc Admixtures Chemical Making Machine

- Tile Hardener Chemical Making Machine

- Tile Hardener Making Machine

- CONCRETE ADMIXTURE MAKING MACHINE

- CHEQUERED TILE HARDENER MAKING MACHINE

- INTERLOCKING BLOCK MAKING MACHINE

- INTERLOCKING TILE MAKING MACHINE

- IRON OXIDE PIGMENT

- KERB STONE MOULDS

- LACQUER POLISH MAKING MACHINE

- Interlocking Block Lacquer Polish Making Machine

- Floor Paint And Floor Coat Making Machine

- Paving Block Lacquer Polish Making Machine

- Interlocking Tile Lacquer Polish Making Machine

- Paver Lacquer Making Machine

- Chequered Tiles High Gloss Lacquer Coating Making Machine

- Designer Tile Lacquer Polish Making Machine

- Lacquer Coating Making Machine

- Lacquer Polish Machine

- Lacquer Polish Making Machine

- Lacquer Sealer Making Machine

- Lacquer Shiner Making Machine

- Paver Block High Gloss Lacquer Polish Making Machine

- Paver Block Lacquer Polish Making Machine

- Tile Coating Machine

- Tile Lacquer Polish Making Machine

- Top Coat Lacquer Making Machine

- Water Base Lacquer Coating Making Machine

- Block Lacquer Polish Making Machine

- Water Proofing Coating Making Machine

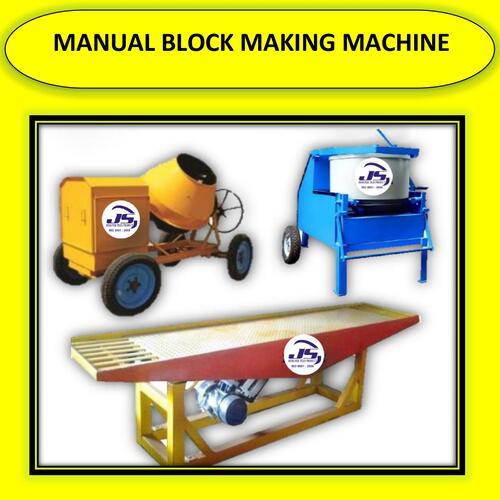

- MANUAL BLOCK MAKING MACHINE

- PAVER BLOCK DEMOULDING MACHINE

- PAVER BLOCK HARDENER

- PAVER BLOCK LACQUER POLISH

- LACQUER COATING FOR PAVER BLOCKS

- TILE LACQUER POLISH

- HIGH GLOSS LACQUER COATING

- ACRYLIC COATINGS

- ACRYLIC LACQUER

- TOP COAT PAVER BLOCK LACQUER

- PAVER BLOCK SHINER

- TILE POLISH

- LACQUER PAINTS

- LIQUID POLISH FOR PAVING BRICKS

- PAVER BLOCK LACQUER COATING

- WATER PROOFING COATING CHEMICAL

- PAVER SEALER

- PAVER COATING LACQUER

- LACQUER COATING

- PAVER LACQUER

- LACQUER POLISH FOR PAVER BLOCKS

- INTERLOCKING TILES POLISH

- LACQUER POLISH

- PAVER BLOCK LACQUER

- LACQUER COLOR COATING CHEMICAL

- HIGH GLOSS LACQUER POLISH

- INTERLOCKING TILE LACQUER POLISH

- PAVER BLOCK PAINT

- NATURAL LACQUER POLISH

- FLOOR PAINT SPECIAL IN PAVER BLOCK & CHEQUERED TILE

- FLOOR PAINT FOR CHEQUERED TILE

- COLOR COATING FOR PAVER BLOCK

- PAVER BLOCK MACHINERY

- PAVER BLOCK MAKING MACHINE

- PAVING BLOCK MOULDS

- SOUTH SET MOULD

- PRECAST PAVER MOULDS

- SILICONE PAVER MOULDS

- ZIG ZAG PAVER MOULD

- V-SHAPE MOULD

- S-SHAPE MOULD

- PAVER BLOCK FARMA

- STAR MOULD

- PAVING BRICK MOULDS

- TRIHEX MOULD

- NEW HEXAGON MOULD

- PAVER BLOCK MOULD

- SQUARE PAVER MOULDS

- PISTON MOULD

- PAVING BLOCK MOULDS

- PAVER MOULDS

- Cement Concrete Tile Lacquer polish making machine

- PVC MOULDS

- PVC PAVER MOULDS

- Pan Mixer Machine

- Color Pan Mixer Machine

- Heavy Duty Pan Mixer Machine

- Paver Block Pan Mixer Machine

- Interlocking Tile Pan Mixer

- PAN MIXER

- Top Layer Pan Mixer

- Top Color Layer Pan Mixer

- Ring Pan Mixer

- Color Pan Mixer

- Paver Block Pan Mixer

- Pan Mixer Machine

- Pan Mixer Machine For Interlocking Tile

- Ring Pan Mixer Machine

- Top Layer Pan Mixer Machine

- RUBBER MOULDS PAVER

- SUPERPLASTICIZER ADMIXTURE

- TILE HARDENER

- TILE MAKING MACHINE

- VIBRATING TABLE

- Designer Vibro Forming

- Heavy Duty Vibro Forming Table

- Paver Designer Tiles Vibro Forming Table

- Vibrator Machine For Paver Block

- Construction Vibro Forming Machine

- Interlocking Block Vibro Forming Machine

- Designer Tile Vibro Forming Table

- Concrete Block Vibro Forming Table

- Designer Tiles Vibro Forming Table

- Interlocking Tile Vibro Forming Machine

- Paver Block Vibro Forming Machine

- VIBRO FORMING MACHINE

- Construction Vibrating Table

- Interlock Vibrating Machine

- HEAVY DUTY VIBRO FORMING TABLE

- PAVER TILE VIBRATING TABLE

- Paver Block Vibrating Table

- Vibro Forming Machine

- Vibro Forming Table Standard

- Tile Vibro Forming Machine

- Vibrating Table Concrete Moulds

- Vibro Table Paver Block Making Machine

- VIBRATING TABLE FOR CONCRETE

- VIBRO FORMING TABLE

- Contact Us

Interlocking Brick Machine

Price 160000 INR/ Piece

MOQ : 1 Piece

Interlocking Brick Machine Specification

- Product Type

- TILE MAKING MACHINE

- General Use

- Industrial

- Method

- Hydraulic Press

- Processing

- Brick Forming

- Automatic

- Semi Automatic

- Power

- 2 HP 3 PHASE Horsepower (HP)

- Voltage

- 240 Volt (v)

- Capacity

- 1000-1500 Bricks Per Hour

- Weight (kg)

- 1500

- Warranty

- 1 YEAR

- Brick Raw Material

- Cement, Fly Ash, Sand

- Type

- Interlocking Brick Machine

- Dimension (L*W*H)

- 2000 x 1000 x 2200 mm

- Color

- Blue & Yellow

- Oil Tank Capacity

- 200 Litres

- Material Feeding

- Manual

- Brick Size Range

- 230 x 110 x 75 mm (customizable)

- Hydraulic Pressure

- 2000 PSI

- Noise Level

- Low (<75 dB)

- Cycle Time

- 12-15 seconds

- Mould Type

- Interchangeable

- Operator Required

- 1-2

- Production Area Required

- 1500 sq. ft.

- Cooling System

- Air Cooled

- Finish Type

- Matte

Interlocking Brick Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 4-5 Days

- Main Domestic Market

- All India

About Interlocking Brick Machine

Interlocking Brick Machine

Js Designer Tiles Product Is A Leading Manufacturer Of Synthetic Silicone Plastic Mould, Synthetic Silicone Rubber Mold, Paver Block Making Machine, Spray Lacquer Polish, Sponge Lacquer Polish, Iron Oxide Etc.

Product details

|

Minimum Order Quantity |

1 Set |

|

Voltage |

240 V |

|

Capacity |

2500.Pcs in 8 Hour |

|

Phase |

Single Phasw |

|

Frequency |

50/60 Hz |

|

Brand |

JS |

|

Material |

Stainless Steel |

Flexible Mould System for Versatile Production

This machine features an interchangeable mould system, enabling rapid changes between different brick sizes and shapes. The customizable design caters to diverse project requirements, making it a practical solution for contractors aiming to produce multiple brick types on the same machine. Operators can easily swap moulds without extensive downtime, increasing overall productivity.

Efficient Operation and Low Resource Requirement

With a quick cycle time of 12-15 seconds and a high hourly capacity, this interlocking brick machine is engineered for efficiency. Its manual material feeding system requires just one or two operators, reducing labor costs. The compact setup fits well within a 1,500 sq. ft. area and runs quietly, making it ideal for various industrial environments.

FAQs of Interlocking Brick Machine:

Q: How does the interchangeable mould system benefit production?

A: The interchangeable mould system allows users to quickly switch between different brick sizes and shapes, enhancing versatility and reducing setup times. This flexibility enables manufacturers to cater to various customer needs without investing in multiple machines.Q: What is the process for operating the interlocking brick machine?

A: Operation involves manually feeding the raw materials (cement, fly ash, sand) into the machine, setting the desired mould, and activating the hydraulic press. The cycle completes in 12-15 seconds, and the semi-automatic mechanism ensures consistent brick forming with minimal operator intervention.Q: When should I perform maintenance on the machine?

A: Routine maintenance should be conducted as per manufacturer guidelines, typically after every few hundred hours of operation. Focus on checking hydraulic fluid levels, inspecting the moulds, and ensuring the air-cooled system is functioning properly for optimal performance.Q: Where can this interlocking brick machine be installed?

A: The machine is designed for industrial settings and requires a minimum production area of 1,500 sq. ft. Due to its low noise levels and air-cooled system, it is suitable for indoor or outdoor factories with adequate ventilation and access to a 240V power supply.Q: What materials can be used as input for this machine?

A: This brick machine works efficiently with a combination of cement, fly ash, and sand. These materials are manually introduced into the feeding hopper, where they are compressed into strong, interlocking bricks using hydraulic pressure.Q: How many operators are required for efficient operation?

A: Only one or two operators are needed to efficiently run this machine. Tasks include material preparation, loading, monitoring production, and performing occasional maintenance, making it a cost-effective solution for brick manufacturing.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in TILE MAKING MACHINE Category

Tile Banane Wali Machine

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 YEAR

Automatic : Other, SemiAutomatic

Product Type : TILE MAKING MACHINE

General Use : Industrial

Manual Block Making Machine

Price 160000 INR / Plant

Minimum Order Quantity : 1 Plant

Warranty : 1 YEAR

Automatic : No

Product Type : TILE MAKING MACHINE

General Use : Industrial

TILE MACHINE MANUFACTURER

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 YEAR

Automatic : Other, SemiAutomatic

Product Type : TILE MAKING MACHINE

General Use : Industrial

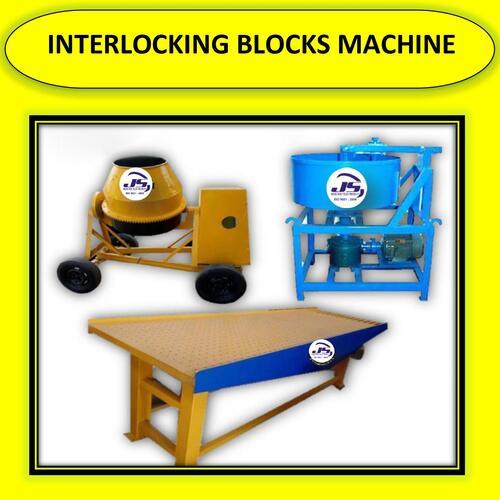

Interlocking Blocks Machine

Price 160000 INR / Piece

Minimum Order Quantity : 1 Pole

Warranty : 1 YEAR

Automatic : No

Product Type : TILE MAKING MACHINE

General Use : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free