- Home Page

- Company Profile

-

Our Products

- CHEMICAL HARDENER

- CHEQUERED TILES MOULD

- COLOR MIXING MACHINE

- CONCRETE BLOCK MOULDS

- HEXAGON KIDA MOULD

- Double Zigzag Mould

- GRASS GRID MOULD

- Milano Paver Block Moulds

- GRASS PAVER MOULD

- L-SHAPE MOULD

- Kaju Katli Paving Block Mould

- MATKA MOULD

- Kida Brooks Mould

- Interlocking Concrete Block Moulds

- Interlocking Paver Moulds

- Mould For Paver Block

- Interlock Block Moulds

- New Damru Mould

- New Cosmic Mould

- CONCRETE CHEMICAL

- CONCRETE HARDENER

- CONCRETE MIXER

- COVER BLOCK MOULDS

- Round Cover Block Mould

- 64 Cavity Pvc Cover Block Mould

- 20,25,30mm 64 Cavity Cover Block Mould

- Multy Cavity Cover Block Mould

- Cover Block Rubber Moulds

- RUBBER COVER BLOCK MOULD

- Square Cover Block Mould

- Concrete Cover Block Moulds

- Cover Block Mould In 20, 25, 40, 50.mm

- 42 Cavity Pvc Cover Block Mould

- Rcc Cover Block Mould

- Cover Block Moulds

- Pvc Cover Block Mould

- Cover Block Moulds Manufacture

- SPACERS RUBBER MOULD

- 49 Cavity Rubber Cover Block Mould

- Cover Block Mould Supplier

- Cover Block Mould 20 & 25.mm

- DESIGNER TILES MOULD

- FLOOR TILES MOULD

- HARDENER MAKING MACHINE

- Paver Block Hardener Making Machine

- Concrete Block Hardener Making Machine

- Hardener Machine

- Interlocking Hardener Machinery

- Interlocking Tile Hardener Making Machine

- Block Hardener Making Machine

- Chemical Hardener Making Machine

- Concrete Hardener Making Machine

- Cover Block Hardener Making Machine

- Designer Tile Hardener Making Machine

- Hardener Making Machine

- Interlocking Block Hardener Making Machine

- Paver Block Clean Mould Releasing Chemical Making Machine

- Paver Chemical Hardener Making Machine

- Paver Hardener Machinery

- Paving Block Hardener Machine

- Rmc Admixtures Chemical Making Machine

- Tile Hardener Chemical Making Machine

- Tile Hardener Making Machine

- CONCRETE ADMIXTURE MAKING MACHINE

- CHEQUERED TILE HARDENER MAKING MACHINE

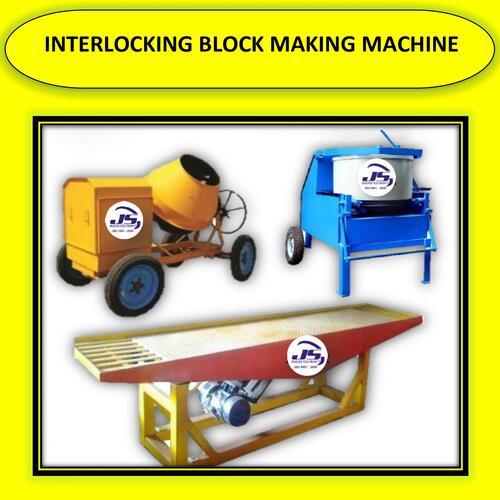

- INTERLOCKING BLOCK MAKING MACHINE

- INTERLOCKING TILE MAKING MACHINE

- IRON OXIDE PIGMENT

- KERB STONE MOULDS

- LACQUER POLISH MAKING MACHINE

- Interlocking Block Lacquer Polish Making Machine

- Floor Paint And Floor Coat Making Machine

- Paving Block Lacquer Polish Making Machine

- Interlocking Tile Lacquer Polish Making Machine

- Paver Lacquer Making Machine

- Chequered Tiles High Gloss Lacquer Coating Making Machine

- Designer Tile Lacquer Polish Making Machine

- Lacquer Coating Making Machine

- Lacquer Polish Machine

- Lacquer Polish Making Machine

- Lacquer Sealer Making Machine

- Lacquer Shiner Making Machine

- Paver Block High Gloss Lacquer Polish Making Machine

- Paver Block Lacquer Polish Making Machine

- Tile Coating Machine

- Tile Lacquer Polish Making Machine

- Top Coat Lacquer Making Machine

- Water Base Lacquer Coating Making Machine

- Block Lacquer Polish Making Machine

- Water Proofing Coating Making Machine

- MANUAL BLOCK MAKING MACHINE

- PAVER BLOCK DEMOULDING MACHINE

- PAVER BLOCK HARDENER

- PAVER BLOCK LACQUER POLISH

- LACQUER COATING FOR PAVER BLOCKS

- TILE LACQUER POLISH

- HIGH GLOSS LACQUER COATING

- ACRYLIC COATINGS

- ACRYLIC LACQUER

- TOP COAT PAVER BLOCK LACQUER

- PAVER BLOCK SHINER

- TILE POLISH

- LACQUER PAINTS

- LIQUID POLISH FOR PAVING BRICKS

- PAVER BLOCK LACQUER COATING

- WATER PROOFING COATING CHEMICAL

- PAVER SEALER

- PAVER COATING LACQUER

- LACQUER COATING

- PAVER LACQUER

- LACQUER POLISH FOR PAVER BLOCKS

- INTERLOCKING TILES POLISH

- LACQUER POLISH

- PAVER BLOCK LACQUER

- LACQUER COLOR COATING CHEMICAL

- HIGH GLOSS LACQUER POLISH

- INTERLOCKING TILE LACQUER POLISH

- PAVER BLOCK PAINT

- NATURAL LACQUER POLISH

- FLOOR PAINT SPECIAL IN PAVER BLOCK & CHEQUERED TILE

- FLOOR PAINT FOR CHEQUERED TILE

- COLOR COATING FOR PAVER BLOCK

- PAVER BLOCK MACHINERY

- PAVER BLOCK MAKING MACHINE

- PAVING BLOCK MOULDS

- SOUTH SET MOULD

- PRECAST PAVER MOULDS

- SILICONE PAVER MOULDS

- ZIG ZAG PAVER MOULD

- V-SHAPE MOULD

- S-SHAPE MOULD

- PAVER BLOCK FARMA

- STAR MOULD

- PAVING BRICK MOULDS

- TRIHEX MOULD

- NEW HEXAGON MOULD

- PAVER BLOCK MOULD

- SQUARE PAVER MOULDS

- PISTON MOULD

- PAVING BLOCK MOULDS

- PAVER MOULDS

- Cement Concrete Tile Lacquer polish making machine

- PVC MOULDS

- PVC PAVER MOULDS

- Pan Mixer Machine

- Color Pan Mixer Machine

- Heavy Duty Pan Mixer Machine

- Paver Block Pan Mixer Machine

- Interlocking Tile Pan Mixer

- PAN MIXER

- Top Layer Pan Mixer

- Top Color Layer Pan Mixer

- Ring Pan Mixer

- Color Pan Mixer

- Paver Block Pan Mixer

- Pan Mixer Machine

- Pan Mixer Machine For Interlocking Tile

- Ring Pan Mixer Machine

- Top Layer Pan Mixer Machine

- RUBBER MOULDS PAVER

- SUPERPLASTICIZER ADMIXTURE

- TILE HARDENER

- TILE MAKING MACHINE

- VIBRATING TABLE

- Designer Vibro Forming

- Heavy Duty Vibro Forming Table

- Paver Designer Tiles Vibro Forming Table

- Vibrator Machine For Paver Block

- Construction Vibro Forming Machine

- Interlocking Block Vibro Forming Machine

- Designer Tile Vibro Forming Table

- Concrete Block Vibro Forming Table

- Designer Tiles Vibro Forming Table

- Interlocking Tile Vibro Forming Machine

- Paver Block Vibro Forming Machine

- VIBRO FORMING MACHINE

- Construction Vibrating Table

- Interlock Vibrating Machine

- HEAVY DUTY VIBRO FORMING TABLE

- PAVER TILE VIBRATING TABLE

- Paver Block Vibrating Table

- Vibro Forming Machine

- Vibro Forming Table Standard

- Tile Vibro Forming Machine

- Vibrating Table Concrete Moulds

- Vibro Table Paver Block Making Machine

- VIBRATING TABLE FOR CONCRETE

- VIBRO FORMING TABLE

- Contact Us

PAVER MANUFACTURING MACHINE

Price 160000 INR/ Piece

MOQ : 1 Piece

PAVER MANUFACTURING MACHINE Specification

- Product Type

- MANUAL BLOCK MAKING MACHINE

- General Use

- Industrial

- Method

- Manual

- Processing

- Hydraulic Compression

- Automatic

- Manual

- Power

- 2 HP 3 PHASE Horsepower (HP)

- Voltage

- 240 Volt (v)

- Capacity

- 1000-1200 Blocks/Day

- Weight (kg)

- 1200

- Warranty

- 1 YEAR

- Brick Raw Material

- Cement, Concrete, Fly Ash

- Type

- Paver Manufacturing Machine

- Dimension (L*W*H)

- 1600 x 1200 x 1500 mm

- Color

- Blue & Yellow

- Material of Construction

- Mild Steel

- Suitable For

- Outdoor, Paving Blocks

- Number of Molds

- Changeable/Multiple Types

- Max Pressure

- 70-100 Ton

- Mould Type

- Interlocking / Zigzag / I Brick / Dumbell / Hexagonal

- Vibration Motor Power

- 0.5 HP

- Operation Mode

- Hand Operated

- Production Per Stroke

- 2-4 Pavers

- Block Height Range

- 25 mm to 80 mm

- Surface Finished

- Paint Coated

- Oil Tank Capacity

- 50 Litres

- Cycle Time

- 15-20 Seconds/Cycle

PAVER MANUFACTURING MACHINE Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 4-5 Days

- Main Domestic Market

- All India

About PAVER MANUFACTURING MACHINE

JS DESIGNER TILES PRODUCT is a leading manufacturer of Synthetic Silicone Plastic Mould, Synthetic Silicone Rubber Mold, Paver Block Making Machine, Spray Lacquer Polish, Sponge Lacquer Polish, Iron Oxide etc.Versatility for Multiple Paving Needs

Designed for adaptability, this paver manufacturing machine accommodates a variety of mould typesincluding interlocking, zigzag, I brick, dumbbell, and hexagonalmaking it suitable for many paving projects. Its adjustable block height range and quick-change molds provide operational flexibility for diverse construction requirements.

Efficient and Reliable Performance

With a capacity to produce 10001200 blocks per day and a cycle time of just 1520 seconds, this machine streamlines the manufacturing process. Its hydraulic compression system, powerful vibration motor, and paint-coated mild steel construction ensure consistent output and low maintenance needs.

Industry-Oriented Build and Support

Manufactured and supplied from India, this machine is tailored for industrial use with a durable build. It features a 1-year warranty and is suitable for use with materials like cement, concrete, and fly ash, offering both exporters and local manufacturers a dependable addition to their production lines.

FAQs of PAVER MANUFACTURING MACHINE:

Q: How does this paver manufacturing machine operate?

A: This machine is hand-operated and utilizes a manual hydraulic compression process. Operators load the raw materials, select the appropriate mold, and initiate the compression cycle, which typically lasts 1520 seconds per stroke.Q: What molding options does the machine offer?

A: It supports multiple interchangeable molds, including interlocking, zigzag, I brick, dumbbell, and hexagonal shapes. This allows businesses to produce a range of paving block designs from a single machine.Q: When should I change the molds, and how is it done?

A: Molds are changed whenever a different block shape is needed. The process is straightforward, allowing operators to swiftly switch out molds to adapt to varying project requirements and designs.Q: Where is this paver machine most effectively used?

A: It is ideally suited for outdoor paving projects, such as sidewalks, driveways, and public spaces that require high-quality concrete, cement, or fly ash pavers.Q: What is the benefit of the machines high-pressure hydraulic system?

A: The powerful hydraulic system, with a pressure range of 70100 tons, ensures that every paver block produced is dense, durable, and has a uniform finish, significantly improving the products quality and longevity.Q: How many blocks can I produce daily with this machine?

A: Under optimal conditions, the machine can manufacture between 1000 and 1200 blocks per day, ensuring high productivity for medium to large paving operations.Q: What warranty and support come with the machine?

A: This paver manufacturing machine includes a 1-year warranty, ensuring manufacturer support for repair or replacement in case of manufacturing defects.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in MANUAL BLOCK MAKING MACHINE Category

Interlocking Block Making Machine

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 2 HP 3 PHASE Horsepower (HP)

Automatic : No

General Use : Industrial

Product Type : MANUAL BLOCK MAKING MACHINE

INTERLOCKING TILES COMPLETE MACHINE

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 2 HP 3 PHASE Horsepower (HP)

Automatic : Other, Manual

General Use : Industrial

Product Type : MANUAL BLOCK MAKING MACHINE

Interlocking Tile Making Machine

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 2 HP 3 PHASE Horsepower (HP)

Automatic : No

General Use : Industrial

Product Type : MANUAL BLOCK MAKING MACHINE

Interlocking Brick Making Machine

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 2 HP 3 PHASE Horsepower (HP)

Automatic : No

General Use : Industrial

Product Type : MANUAL BLOCK MAKING MACHINE

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free