- Home Page

- Company Profile

-

Our Products

- CHEMICAL HARDENER

- CHEQUERED TILES MOULD

- COLOR MIXING MACHINE

- CONCRETE BLOCK MOULDS

- HEXAGON KIDA MOULD

- Double Zigzag Mould

- GRASS GRID MOULD

- Milano Paver Block Moulds

- GRASS PAVER MOULD

- L-SHAPE MOULD

- Kaju Katli Paving Block Mould

- MATKA MOULD

- Kida Brooks Mould

- Interlocking Concrete Block Moulds

- Interlocking Paver Moulds

- Mould For Paver Block

- Interlock Block Moulds

- New Damru Mould

- New Cosmic Mould

- CONCRETE CHEMICAL

- CONCRETE HARDENER

- CONCRETE MIXER

- COVER BLOCK MOULDS

- Round Cover Block Mould

- 64 Cavity Pvc Cover Block Mould

- 20,25,30mm 64 Cavity Cover Block Mould

- Multy Cavity Cover Block Mould

- Cover Block Rubber Moulds

- RUBBER COVER BLOCK MOULD

- Square Cover Block Mould

- Concrete Cover Block Moulds

- Cover Block Mould In 20, 25, 40, 50.mm

- 42 Cavity Pvc Cover Block Mould

- Rcc Cover Block Mould

- Cover Block Moulds

- Pvc Cover Block Mould

- Cover Block Moulds Manufacture

- SPACERS RUBBER MOULD

- 49 Cavity Rubber Cover Block Mould

- Cover Block Mould Supplier

- Cover Block Mould 20 & 25.mm

- DESIGNER TILES MOULD

- FLOOR TILES MOULD

- HARDENER MAKING MACHINE

- Paver Block Hardener Making Machine

- Concrete Block Hardener Making Machine

- Hardener Machine

- Interlocking Hardener Machinery

- Interlocking Tile Hardener Making Machine

- Block Hardener Making Machine

- Chemical Hardener Making Machine

- Concrete Hardener Making Machine

- Cover Block Hardener Making Machine

- Designer Tile Hardener Making Machine

- Hardener Making Machine

- Interlocking Block Hardener Making Machine

- Paver Block Clean Mould Releasing Chemical Making Machine

- Paver Chemical Hardener Making Machine

- Paver Hardener Machinery

- Paving Block Hardener Machine

- Rmc Admixtures Chemical Making Machine

- Tile Hardener Chemical Making Machine

- Tile Hardener Making Machine

- CONCRETE ADMIXTURE MAKING MACHINE

- CHEQUERED TILE HARDENER MAKING MACHINE

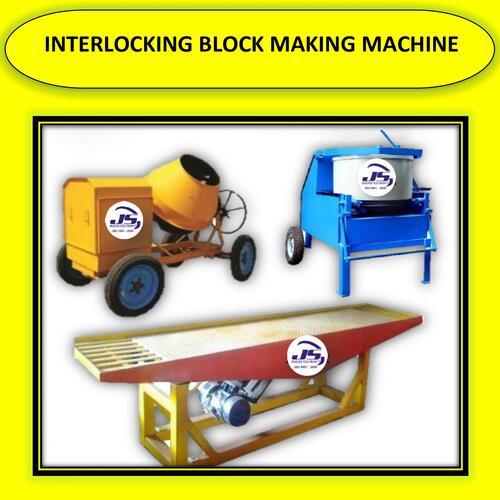

- INTERLOCKING BLOCK MAKING MACHINE

- INTERLOCKING TILE MAKING MACHINE

- IRON OXIDE PIGMENT

- KERB STONE MOULDS

- LACQUER POLISH MAKING MACHINE

- Interlocking Block Lacquer Polish Making Machine

- Floor Paint And Floor Coat Making Machine

- Paving Block Lacquer Polish Making Machine

- Interlocking Tile Lacquer Polish Making Machine

- Paver Lacquer Making Machine

- Chequered Tiles High Gloss Lacquer Coating Making Machine

- Designer Tile Lacquer Polish Making Machine

- Lacquer Coating Making Machine

- Lacquer Polish Machine

- Lacquer Polish Making Machine

- Lacquer Sealer Making Machine

- Lacquer Shiner Making Machine

- Paver Block High Gloss Lacquer Polish Making Machine

- Paver Block Lacquer Polish Making Machine

- Tile Coating Machine

- Tile Lacquer Polish Making Machine

- Top Coat Lacquer Making Machine

- Water Base Lacquer Coating Making Machine

- Block Lacquer Polish Making Machine

- Water Proofing Coating Making Machine

- MANUAL BLOCK MAKING MACHINE

- PAVER BLOCK DEMOULDING MACHINE

- PAVER BLOCK HARDENER

- PAVER BLOCK LACQUER POLISH

- LACQUER COATING FOR PAVER BLOCKS

- TILE LACQUER POLISH

- HIGH GLOSS LACQUER COATING

- ACRYLIC COATINGS

- ACRYLIC LACQUER

- TOP COAT PAVER BLOCK LACQUER

- PAVER BLOCK SHINER

- TILE POLISH

- LACQUER PAINTS

- LIQUID POLISH FOR PAVING BRICKS

- PAVER BLOCK LACQUER COATING

- WATER PROOFING COATING CHEMICAL

- PAVER SEALER

- PAVER COATING LACQUER

- LACQUER COATING

- PAVER LACQUER

- LACQUER POLISH FOR PAVER BLOCKS

- INTERLOCKING TILES POLISH

- LACQUER POLISH

- PAVER BLOCK LACQUER

- LACQUER COLOR COATING CHEMICAL

- HIGH GLOSS LACQUER POLISH

- INTERLOCKING TILE LACQUER POLISH

- PAVER BLOCK PAINT

- NATURAL LACQUER POLISH

- FLOOR PAINT SPECIAL IN PAVER BLOCK & CHEQUERED TILE

- FLOOR PAINT FOR CHEQUERED TILE

- COLOR COATING FOR PAVER BLOCK

- PAVER BLOCK MACHINERY

- PAVER BLOCK MAKING MACHINE

- PAVING BLOCK MOULDS

- SOUTH SET MOULD

- PRECAST PAVER MOULDS

- SILICONE PAVER MOULDS

- ZIG ZAG PAVER MOULD

- V-SHAPE MOULD

- S-SHAPE MOULD

- PAVER BLOCK FARMA

- STAR MOULD

- PAVING BRICK MOULDS

- TRIHEX MOULD

- NEW HEXAGON MOULD

- PAVER BLOCK MOULD

- SQUARE PAVER MOULDS

- PISTON MOULD

- PAVING BLOCK MOULDS

- PAVER MOULDS

- Cement Concrete Tile Lacquer polish making machine

- PVC MOULDS

- PVC PAVER MOULDS

- Pan Mixer Machine

- Color Pan Mixer Machine

- Heavy Duty Pan Mixer Machine

- Paver Block Pan Mixer Machine

- Interlocking Tile Pan Mixer

- PAN MIXER

- Top Layer Pan Mixer

- Top Color Layer Pan Mixer

- Ring Pan Mixer

- Color Pan Mixer

- Paver Block Pan Mixer

- Pan Mixer Machine

- Pan Mixer Machine For Interlocking Tile

- Ring Pan Mixer Machine

- Top Layer Pan Mixer Machine

- RUBBER MOULDS PAVER

- SUPERPLASTICIZER ADMIXTURE

- TILE HARDENER

- TILE MAKING MACHINE

- VIBRATING TABLE

- Designer Vibro Forming

- Heavy Duty Vibro Forming Table

- Paver Designer Tiles Vibro Forming Table

- Vibrator Machine For Paver Block

- Construction Vibro Forming Machine

- Interlocking Block Vibro Forming Machine

- Designer Tile Vibro Forming Table

- Concrete Block Vibro Forming Table

- Designer Tiles Vibro Forming Table

- Interlocking Tile Vibro Forming Machine

- Paver Block Vibro Forming Machine

- VIBRO FORMING MACHINE

- Construction Vibrating Table

- Interlock Vibrating Machine

- HEAVY DUTY VIBRO FORMING TABLE

- PAVER TILE VIBRATING TABLE

- Paver Block Vibrating Table

- Vibro Forming Machine

- Vibro Forming Table Standard

- Tile Vibro Forming Machine

- Vibrating Table Concrete Moulds

- Vibro Table Paver Block Making Machine

- VIBRATING TABLE FOR CONCRETE

- VIBRO FORMING TABLE

- Contact Us

Interlocking Block Making Machine

Price 160000 INR/ Piece

MOQ : 1 Piece

Interlocking Block Making Machine Specification

- Product Type

- MANUAL BLOCK MAKING MACHINE

- General Use

- Industrial

- Method

- Manual

- Processing

- Brick Molding

- Automatic

- No

- Power

- 2 HP 3 PHASE Horsepower (HP)

- Voltage

- 240 Volt (v)

- Capacity

- 1000-1500 blocks/8 hours

- Weight (kg)

- 450

- Warranty

- 1 YEAR

- Brick Raw Material

- Cement, Sand, Stone Dust, Fly Ash

- Type

- Interlocking Block Making Machine

- Dimension (L*W*H)

- 1750 x 1250 x 1750 mm

- Color

- Blue and Yellow

- Molding Area

- 500 x 250 mm

- Material of Construction

- Mild Steel

- Manpower Required

- 2 Persons

- Cycle Time

- 20-25 seconds per block

- Block Type

- Interlocking, Paver, Solid

- Maximum Pressure

- 5-7 Tons

- Surface Finish

- Paint Coated

Interlocking Block Making Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 4-5 Days

- Main Domestic Market

- All India

About Interlocking Block Making Machine

Interlocking Block Making Machine

Js Designer Tiles Product Is A Leading Manufacturer Of Synthetic Silicone Plastic Mould, Synthetic Silicone Rubber Mold, Paver Block Making Machine, Spray Lacquer Polish, Sponge Lacquer Polish, Iron Oxide Etc.

Product details

|

Minimum Order Quantity |

1 Set |

|

Block Type |

paver,Solid and interlocking tile making machine |

|

Brand/Make |

JS |

|

Method |

Hydraulic Pressure |

|

Raw Material |

Cement |

|

Warranty |

1 Year |

|

Automation Grade |

Automatic |

Efficient Block Production

With a processing capacity of up to 1500 blocks in an 8-hour workday, this machine streamlines industrial block manufacturing. The quick 20-25 second cycle time per block helps boost productivity while maintaining consistent quality. Its large molding area accommodates diverse block types, catering to various construction needs.

Robust Design and Construction

Manufactured from durable mild steel and finished with a high-quality paint coating, this machine is built for longevity in demanding environments. The compact 1750 x 1250 x 1750 mm footprint allows easy integration into existing production lines while ensuring stable operation during intense usage.

User-Friendly Operation

This manually operated block making machine requires only two operators, minimizing labor costs and ensuring straightforward operation. It functions efficiently on a standard 240-volt, 3-phase power supply with a 2 HP motor, making it suitable for various industrial setups across India and other regions.

FAQs of Interlocking Block Making Machine:

Q: How does the block making process work with this machine?

A: The manual method involves placing a mixture of cement, sand, stone dust, and fly ash into the mold area. Once the material is positioned, the machine applies 5-7 tons of pressure to form the block, releasing a finished product in 20-25 seconds per cycle.Q: What types of blocks can be produced with this machine?

A: This Interlocking Block Making Machine produces interlocking blocks, paver blocks, and solid blocks, making it versatile for various industrial and construction applications.Q: When is routine maintenance recommended for optimal performance?

A: Routine maintenance should be performed every two to three months or as needed, focusing on cleaning, checking bolts, lubricating moving parts, and inspecting the paint coating for any signs of wear or rust.Q: Where can this machine be installed for best results?

A: For optimal performance, install the machine in a level, sheltered industrial setting with access to a 240-volt, 3-phase power supply and sufficient raw materials. Its compact size allows it to fit neatly into most factory layouts.Q: What are the key operational requirements?

A: The machine requires two people for manual handling, connection to a 240-volt, 3-phase power supply, and readily available cement, sand, stone dust, and fly ash materials.Q: What are the main benefits of using this block making machine?

A: Its high output, robust construction, and low labor needs make this machine highly cost-effective for industrial block production. The 1-year warranty and durable design ensure dependable, long-lasting operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in MANUAL BLOCK MAKING MACHINE Category

INTERLOCKING TILES COMPLETE MACHINE

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, Manual

Warranty : 1 YEAR

Product Type : MANUAL BLOCK MAKING MACHINE

Power : 2 HP 3 PHASE Horsepower (HP)

PAVER MANUFACTURING MACHINE

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, Manual

Warranty : 1 YEAR

Product Type : MANUAL BLOCK MAKING MACHINE

Power : 2 HP 3 PHASE Horsepower (HP)

Interlocking Brick Making Machine

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

Warranty : 1 YEAR

Product Type : MANUAL BLOCK MAKING MACHINE

Power : 2 HP 3 PHASE Horsepower (HP)

Interlocking Tile Making Machine

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

Warranty : 1 YEAR

Product Type : MANUAL BLOCK MAKING MACHINE

Power : 2 HP 3 PHASE Horsepower (HP)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS