- Home Page

- Company Profile

-

Our Products

- CHEMICAL HARDENER

- CHEQUERED TILES MOULD

- COLOR MIXING MACHINE

- CONCRETE BLOCK MOULDS

- HEXAGON KIDA MOULD

- Double Zigzag Mould

- GRASS GRID MOULD

- Milano Paver Block Moulds

- GRASS PAVER MOULD

- L-SHAPE MOULD

- Kaju Katli Paving Block Mould

- MATKA MOULD

- Kida Brooks Mould

- Interlocking Concrete Block Moulds

- Interlocking Paver Moulds

- Mould For Paver Block

- Interlock Block Moulds

- New Damru Mould

- New Cosmic Mould

- CONCRETE CHEMICAL

- CONCRETE HARDENER

- CONCRETE MIXER

- COVER BLOCK MOULDS

- Round Cover Block Mould

- 64 Cavity Pvc Cover Block Mould

- 20,25,30mm 64 Cavity Cover Block Mould

- Multy Cavity Cover Block Mould

- Cover Block Rubber Moulds

- RUBBER COVER BLOCK MOULD

- Square Cover Block Mould

- Concrete Cover Block Moulds

- Cover Block Mould In 20, 25, 40, 50.mm

- 42 Cavity Pvc Cover Block Mould

- Rcc Cover Block Mould

- Cover Block Moulds

- Pvc Cover Block Mould

- Cover Block Moulds Manufacture

- SPACERS RUBBER MOULD

- 49 Cavity Rubber Cover Block Mould

- Cover Block Mould Supplier

- Cover Block Mould 20 & 25.mm

- DESIGNER TILES MOULD

- FLOOR TILES MOULD

- HARDENER MAKING MACHINE

- Paver Block Hardener Making Machine

- Concrete Block Hardener Making Machine

- Hardener Machine

- Interlocking Hardener Machinery

- Interlocking Tile Hardener Making Machine

- Block Hardener Making Machine

- Chemical Hardener Making Machine

- Concrete Hardener Making Machine

- Cover Block Hardener Making Machine

- Designer Tile Hardener Making Machine

- Hardener Making Machine

- Interlocking Block Hardener Making Machine

- Paver Block Clean Mould Releasing Chemical Making Machine

- Paver Chemical Hardener Making Machine

- Paver Hardener Machinery

- Paving Block Hardener Machine

- Rmc Admixtures Chemical Making Machine

- Tile Hardener Chemical Making Machine

- Tile Hardener Making Machine

- CONCRETE ADMIXTURE MAKING MACHINE

- CHEQUERED TILE HARDENER MAKING MACHINE

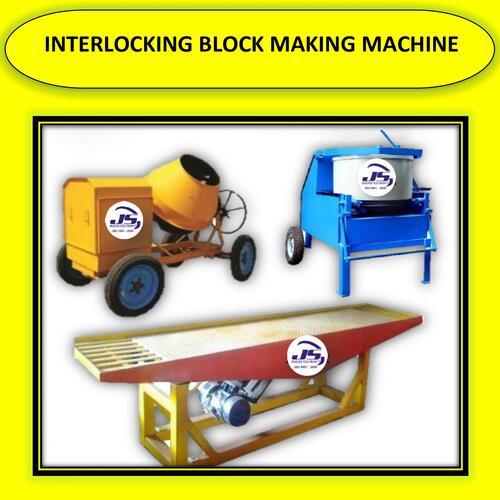

- INTERLOCKING BLOCK MAKING MACHINE

- INTERLOCKING TILE MAKING MACHINE

- IRON OXIDE PIGMENT

- KERB STONE MOULDS

- LACQUER POLISH MAKING MACHINE

- Interlocking Block Lacquer Polish Making Machine

- Floor Paint And Floor Coat Making Machine

- Paving Block Lacquer Polish Making Machine

- Interlocking Tile Lacquer Polish Making Machine

- Paver Lacquer Making Machine

- Chequered Tiles High Gloss Lacquer Coating Making Machine

- Designer Tile Lacquer Polish Making Machine

- Lacquer Coating Making Machine

- Lacquer Polish Machine

- Lacquer Polish Making Machine

- Lacquer Sealer Making Machine

- Lacquer Shiner Making Machine

- Paver Block High Gloss Lacquer Polish Making Machine

- Paver Block Lacquer Polish Making Machine

- Tile Coating Machine

- Tile Lacquer Polish Making Machine

- Top Coat Lacquer Making Machine

- Water Base Lacquer Coating Making Machine

- Block Lacquer Polish Making Machine

- Water Proofing Coating Making Machine

- MANUAL BLOCK MAKING MACHINE

- PAVER BLOCK DEMOULDING MACHINE

- PAVER BLOCK HARDENER

- PAVER BLOCK LACQUER POLISH

- LACQUER COATING FOR PAVER BLOCKS

- TILE LACQUER POLISH

- HIGH GLOSS LACQUER COATING

- ACRYLIC COATINGS

- ACRYLIC LACQUER

- TOP COAT PAVER BLOCK LACQUER

- PAVER BLOCK SHINER

- TILE POLISH

- LACQUER PAINTS

- LIQUID POLISH FOR PAVING BRICKS

- PAVER BLOCK LACQUER COATING

- WATER PROOFING COATING CHEMICAL

- PAVER SEALER

- PAVER COATING LACQUER

- LACQUER COATING

- PAVER LACQUER

- LACQUER POLISH FOR PAVER BLOCKS

- INTERLOCKING TILES POLISH

- LACQUER POLISH

- PAVER BLOCK LACQUER

- LACQUER COLOR COATING CHEMICAL

- HIGH GLOSS LACQUER POLISH

- INTERLOCKING TILE LACQUER POLISH

- PAVER BLOCK PAINT

- NATURAL LACQUER POLISH

- FLOOR PAINT SPECIAL IN PAVER BLOCK & CHEQUERED TILE

- FLOOR PAINT FOR CHEQUERED TILE

- COLOR COATING FOR PAVER BLOCK

- PAVER BLOCK MACHINERY

- PAVER BLOCK MAKING MACHINE

- PAVING BLOCK MOULDS

- SOUTH SET MOULD

- PRECAST PAVER MOULDS

- SILICONE PAVER MOULDS

- ZIG ZAG PAVER MOULD

- V-SHAPE MOULD

- S-SHAPE MOULD

- PAVER BLOCK FARMA

- STAR MOULD

- PAVING BRICK MOULDS

- TRIHEX MOULD

- NEW HEXAGON MOULD

- PAVER BLOCK MOULD

- SQUARE PAVER MOULDS

- PISTON MOULD

- PAVING BLOCK MOULDS

- PAVER MOULDS

- Cement Concrete Tile Lacquer polish making machine

- PVC MOULDS

- PVC PAVER MOULDS

- Pan Mixer Machine

- Color Pan Mixer Machine

- Heavy Duty Pan Mixer Machine

- Paver Block Pan Mixer Machine

- Interlocking Tile Pan Mixer

- PAN MIXER

- Top Layer Pan Mixer

- Top Color Layer Pan Mixer

- Ring Pan Mixer

- Color Pan Mixer

- Paver Block Pan Mixer

- Pan Mixer Machine

- Pan Mixer Machine For Interlocking Tile

- Ring Pan Mixer Machine

- Top Layer Pan Mixer Machine

- RUBBER MOULDS PAVER

- SUPERPLASTICIZER ADMIXTURE

- TILE HARDENER

- TILE MAKING MACHINE

- VIBRATING TABLE

- Designer Vibro Forming

- Heavy Duty Vibro Forming Table

- Paver Designer Tiles Vibro Forming Table

- Vibrator Machine For Paver Block

- Construction Vibro Forming Machine

- Interlocking Block Vibro Forming Machine

- Designer Tile Vibro Forming Table

- Concrete Block Vibro Forming Table

- Designer Tiles Vibro Forming Table

- Interlocking Tile Vibro Forming Machine

- Paver Block Vibro Forming Machine

- VIBRO FORMING MACHINE

- Construction Vibrating Table

- Interlock Vibrating Machine

- HEAVY DUTY VIBRO FORMING TABLE

- PAVER TILE VIBRATING TABLE

- Paver Block Vibrating Table

- Vibro Forming Machine

- Vibro Forming Table Standard

- Tile Vibro Forming Machine

- Vibrating Table Concrete Moulds

- Vibro Table Paver Block Making Machine

- VIBRATING TABLE FOR CONCRETE

- VIBRO FORMING TABLE

- Contact Us

Interlocking Tile Making Machine

Price 160000 INR/ Piece

MOQ : 1 Piece

Interlocking Tile Making Machine Specification

- Product Type

- MANUAL BLOCK MAKING MACHINE

- General Use

- Industrial

- Method

- Manual

- Processing

- Tile Forming

- Automatic

- No

- Power

- 2 HP 3 PHASE Horsepower (HP)

- Voltage

- 240 Volt (v)

- Capacity

- 1500 - 2000 tiles per 8 hr shift

- Weight (kg)

- 450

- Warranty

- 1 YEAR

- Brick Raw Material

- Cement, Sand, Stone Dust, Pigments

- Type

- Interlocking Tile Making Machine

- Dimension (L*W*H)

- 1500 mm x 600 mm x 1200 mm

- Color

- Blue

- Material of Construction

- Mild Steel

- Minimum Order Quantity

- 1 Unit

- Vibration System

- Heavy-duty vibration system for compaction

- Cycle Time

- 30-60 seconds per stroke

- Noise Level

- Low

- Production Per Stroke

- 2 Tiles

- Operating System

- Hand lever operated

- Moulds Included

- Interchangeable for different tile shapes

- Surface Finish

- Powder coated

Interlocking Tile Making Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 4-5 Days

- Main Domestic Market

- All India

About Interlocking Tile Making Machine

Interlocking Tile Making Machine

Js Designer Tiles Product Is A Leading Manufacturer Of Synthetic Silicone Plastic Mould, Synthetic Silicone Rubber Mold, Paver Block Making Machine, Spray Lacquer Polish, Sponge Lacquer Polish, Iron Oxide Etc.

Product details

|

Minimum Order Quantity |

1 Set |

|

Frequency |

50/60 Hz |

|

Brand/Make |

JS |

|

Capacity |

2500 Pcs in 8 Hour |

|

Voltage |

240 V |

|

Phase |

Single Phase |

|

Material |

Stainless Steel |

|

Power Source |

Electric |

Efficient Tile Manufacturing

Engineered for reliability and productivity, the Interlocking Tile Making Machine simplifies the production process while ensuring high-quality results. By using interchangeable moulds, businesses can swiftly switch between tile designs, meeting diverse market demands with minimum downtime and effort.

Rugged Construction & Consistent Output

Built from sturdy mild steel and finished with powder coating, the machine guarantees longevity and resistance to wear. The robust vibration system delivers consistent compaction, leading to durable, precisely shaped tiles with each cycle while maintaining low operational noise.

FAQs of Interlocking Tile Making Machine:

Q: How does the interchangeable mould feature enhance production flexibility?

A: The interchangeable moulds allow users to easily switch between different tile shapes and sizes without needing multiple machines, offering adaptability to varied design requirements and customer preferences.Q: What are the steps involved in operating this tile making machine?

A: To operate, place the prepared cement, sand, stone dust, and pigment mixture into the chosen mould, engage the hand lever to initiate the vibration system for compaction, and after 3060 seconds, release the lever to retrieve the formed tiles. Repeat for continuous production.Q: When is the optimal time for production with this machine?

A: The machine is designed for continuous operation, making it ideal for use throughout an 8-hour industrial shift, where it can produce between 1500 to 2000 tiles depending on operational efficiency.Q: Where can this machine be installed and used?

A: This machine is suitable for industrial settings, such as tile manufacturing units or brickworks, and can be conveniently installed in facilities with access to 240V three-phase electricity.Q: What materials can be processed with this tile making machine?

A: The machine is built to work with a mixture of cement, sand, stone dust, and pigments, ensuring compatibility with common tile manufacturing raw materials for robust and attractive tile output.Q: Why choose this manual tile making machine over automatic options?

A: The manual operation allows for precise control over each production cycle, requires less maintenance, and reduces upfront investment compared to automatic systems, making it ideal for small to medium-scale producers.Q: What are the main benefits of using this machine for tile production?

A: Key benefits include fast cycle times, low noise, high output per shift, durable construction, ease of maintenance, and the versatility offered by mould interchangeability, all backed by a 1-year warranty.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in MANUAL BLOCK MAKING MACHINE Category

Interlocking Block Making Machine

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : MANUAL BLOCK MAKING MACHINE

Warranty : 1 YEAR

Automatic : No

Voltage : 240 Volt (v)

INTERLOCKING TILES COMPLETE MACHINE

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : MANUAL BLOCK MAKING MACHINE

Warranty : 1 YEAR

Automatic : Other, Manual

Voltage : 240 Volt (v)

Interlocking Brick Making Machine

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : MANUAL BLOCK MAKING MACHINE

Warranty : 1 YEAR

Automatic : No

Voltage : 240 Volt (v)

PAVER MANUFACTURING MACHINE

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : MANUAL BLOCK MAKING MACHINE

Warranty : 1 YEAR

Automatic : Other, Manual

Voltage : 240 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free