- Home Page

- Company Profile

-

Our Products

- CHEMICAL HARDENER

- CHEQUERED TILES MOULD

- COLOR MIXING MACHINE

- CONCRETE BLOCK MOULDS

- HEXAGON KIDA MOULD

- Kida Brooks Mould

- Mould For Paver Block

- Interlocking Paver Moulds

- Interlock Block Moulds

- Interlocking Concrete Block Moulds

- Double Zigzag Mould

- GRASS GRID MOULD

- Milano Paver Block Moulds

- GRASS PAVER MOULD

- L-SHAPE MOULD

- Kaju Katli Paving Block Mould

- MATKA MOULD

- New Damru Mould

- New Cosmic Mould

- CONCRETE CHEMICAL

- CONCRETE HARDENER

- CONCRETE MIXER

- COVER BLOCK MOULDS

- SPACERS RUBBER MOULD

- Concrete Cover Block Moulds

- Cover Block Moulds Manufacture

- Cover Block Mould In 20, 25, 40, 50.mm

- Cover Block Mould 20 & 25.mm

- 42 Cavity Pvc Cover Block Mould

- 20,25,30mm 64 Cavity Cover Block Mould

- Multy Cavity Cover Block Mould

- Cover Block Rubber Moulds

- RUBBER COVER BLOCK MOULD

- 49 Cavity Rubber Cover Block Mould

- Rcc Cover Block Mould

- Round Cover Block Mould

- Square Cover Block Mould

- Cover Block Mould Supplier

- Pvc Cover Block Mould

- 64 Cavity Pvc Cover Block Mould

- Cover Block Moulds

- DESIGNER TILES MOULD

- FLOOR TILES MOULD

- HARDENER MAKING MACHINE

- Paver Block Hardener Making Machine

- Concrete Block Hardener Making Machine

- Hardener Machine

- Interlocking Hardener Machinery

- Interlocking Tile Hardener Making Machine

- Block Hardener Making Machine

- Chemical Hardener Making Machine

- Concrete Hardener Making Machine

- Cover Block Hardener Making Machine

- Designer Tile Hardener Making Machine

- Hardener Making Machine

- Interlocking Block Hardener Making Machine

- Paver Block Clean Mould Releasing Chemical Making Machine

- Paver Chemical Hardener Making Machine

- Paver Hardener Machinery

- Paving Block Hardener Machine

- Rmc Admixtures Chemical Making Machine

- Tile Hardener Chemical Making Machine

- Tile Hardener Making Machine

- CONCRETE ADMIXTURE MAKING MACHINE

- CHEQUERED TILE HARDENER MAKING MACHINE

- INTERLOCKING BLOCK MAKING MACHINE

- INTERLOCKING TILE MAKING MACHINE

- IRON OXIDE PIGMENT

- KERB STONE MOULDS

- LACQUER POLISH MAKING MACHINE

- Interlocking Block Lacquer Polish Making Machine

- Floor Paint And Floor Coat Making Machine

- Paving Block Lacquer Polish Making Machine

- Interlocking Tile Lacquer Polish Making Machine

- Paver Lacquer Making Machine

- Chequered Tiles High Gloss Lacquer Coating Making Machine

- Designer Tile Lacquer Polish Making Machine

- Lacquer Coating Making Machine

- Lacquer Polish Machine

- Lacquer Polish Making Machine

- Lacquer Sealer Making Machine

- Lacquer Shiner Making Machine

- Paver Block High Gloss Lacquer Polish Making Machine

- Paver Block Lacquer Polish Making Machine

- Tile Coating Machine

- Tile Lacquer Polish Making Machine

- Top Coat Lacquer Making Machine

- Water Base Lacquer Coating Making Machine

- Block Lacquer Polish Making Machine

- Water Proofing Coating Making Machine

- MANUAL BLOCK MAKING MACHINE

- PAVER BLOCK DEMOULDING MACHINE

- PAVER BLOCK HARDENER

- PAVER BLOCK LACQUER POLISH

- LACQUER COATING FOR PAVER BLOCKS

- HIGH GLOSS LACQUER COATING

- ACRYLIC COATINGS

- TILE LACQUER POLISH

- PAVER BLOCK SHINER

- TOP COAT PAVER BLOCK LACQUER

- ACRYLIC LACQUER

- LIQUID POLISH FOR PAVING BRICKS

- TILE POLISH

- LACQUER PAINTS

- WATER PROOFING COATING CHEMICAL

- PAVER SEALER

- PAVER BLOCK LACQUER COATING

- PAVER COATING LACQUER

- LACQUER COATING

- PAVER LACQUER

- LACQUER POLISH FOR PAVER BLOCKS

- INTERLOCKING TILES POLISH

- LACQUER POLISH

- PAVER BLOCK LACQUER

- LACQUER COLOR COATING CHEMICAL

- HIGH GLOSS LACQUER POLISH

- INTERLOCKING TILE LACQUER POLISH

- PAVER BLOCK PAINT

- NATURAL LACQUER POLISH

- FLOOR PAINT SPECIAL IN PAVER BLOCK & CHEQUERED TILE

- FLOOR PAINT FOR CHEQUERED TILE

- COLOR COATING FOR PAVER BLOCK

- PAVER BLOCK MACHINERY

- PAVER BLOCK MAKING MACHINE

- PAVING BLOCK MOULDS

- ZIG ZAG PAVER MOULD

- V-SHAPE MOULD

- S-SHAPE MOULD

- PAVER BLOCK MOULD

- PAVER BLOCK FARMA

- STAR MOULD

- TRIHEX MOULD

- SQUARE PAVER MOULDS

- SOUTH SET MOULD

- SILICONE PAVER MOULDS

- PRECAST PAVER MOULDS

- NEW HEXAGON MOULD

- PISTON MOULD

- PAVER MOULDS

- PAVING BRICK MOULDS

- PAVING BLOCK MOULDS

- Cement Concrete Tile Lacquer polish making machine

- PVC MOULDS

- PVC PAVER MOULDS

- Pan Mixer Machine

- Paver Block Pan Mixer Machine

- Color Pan Mixer Machine

- Heavy Duty Pan Mixer Machine

- Interlocking Tile Pan Mixer

- PAN MIXER

- Top Layer Pan Mixer

- Top Color Layer Pan Mixer

- Ring Pan Mixer

- Color Pan Mixer

- Paver Block Pan Mixer

- Pan Mixer Machine

- Pan Mixer Machine For Interlocking Tile

- Ring Pan Mixer Machine

- Top Layer Pan Mixer Machine

- RUBBER MOULDS PAVER

- SUPERPLASTICIZER ADMIXTURE

- TILE HARDENER

- TILE MAKING MACHINE

- VIBRATING TABLE

- Designer Vibro Forming

- Construction Vibro Forming Machine

- Designer Tile Vibro Forming Table

- Vibrator Machine For Paver Block

- Interlocking Block Vibro Forming Machine

- Heavy Duty Vibro Forming Table

- Paver Designer Tiles Vibro Forming Table

- Concrete Block Vibro Forming Table

- Designer Tiles Vibro Forming Table

- Interlocking Tile Vibro Forming Machine

- Paver Block Vibro Forming Machine

- VIBRO FORMING MACHINE

- PAVER TILE VIBRATING TABLE

- Construction Vibrating Table

- Interlock Vibrating Machine

- HEAVY DUTY VIBRO FORMING TABLE

- Paver Block Vibrating Table

- Vibro Forming Machine

- Vibro Forming Table Standard

- Tile Vibro Forming Machine

- Vibrating Table Concrete Moulds

- Vibro Table Paver Block Making Machine

- VIBRATING TABLE FOR CONCRETE

- VIBRO FORMING TABLE

- Contact Us

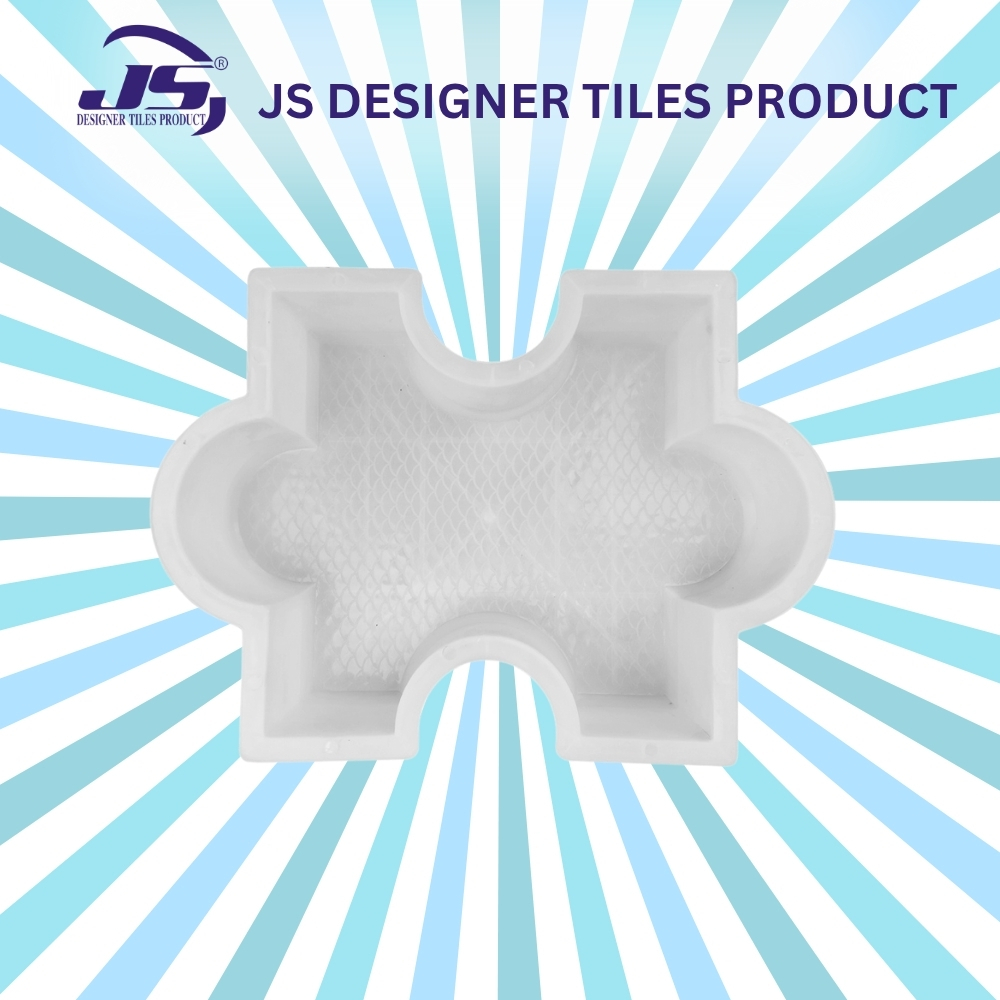

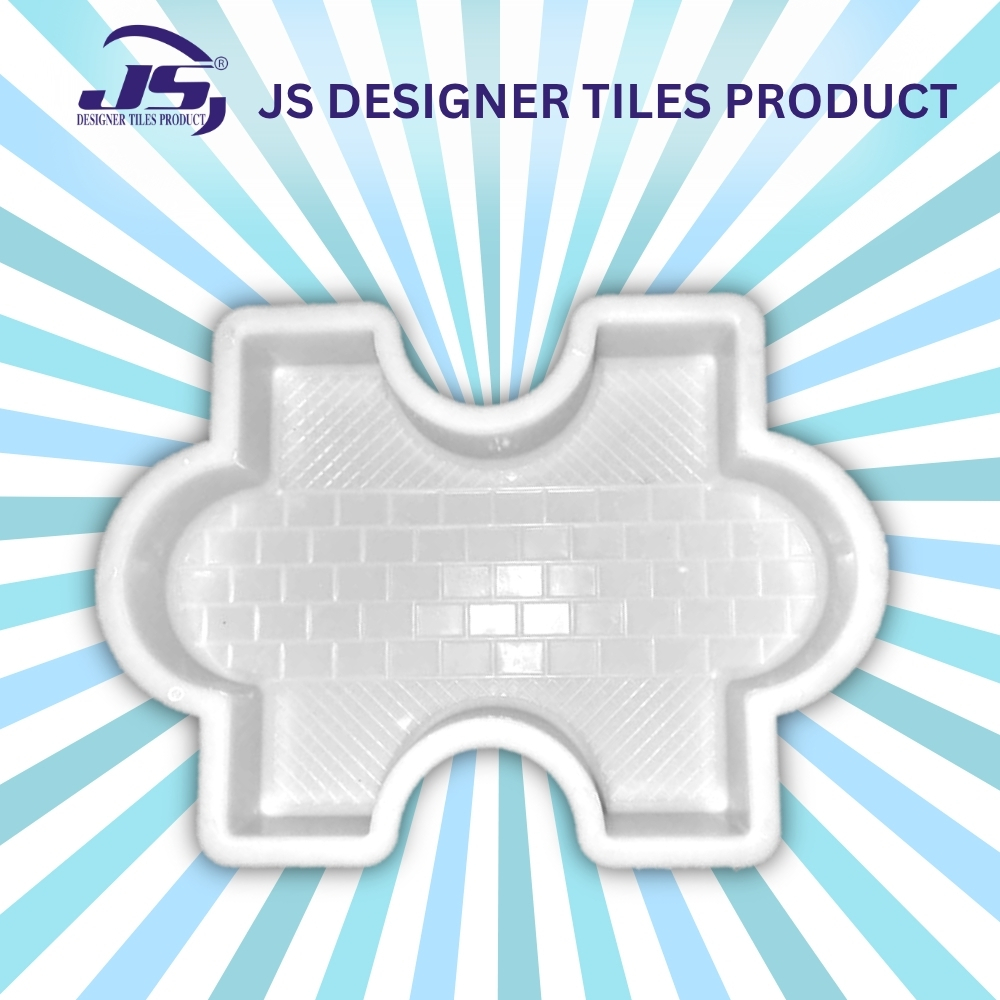

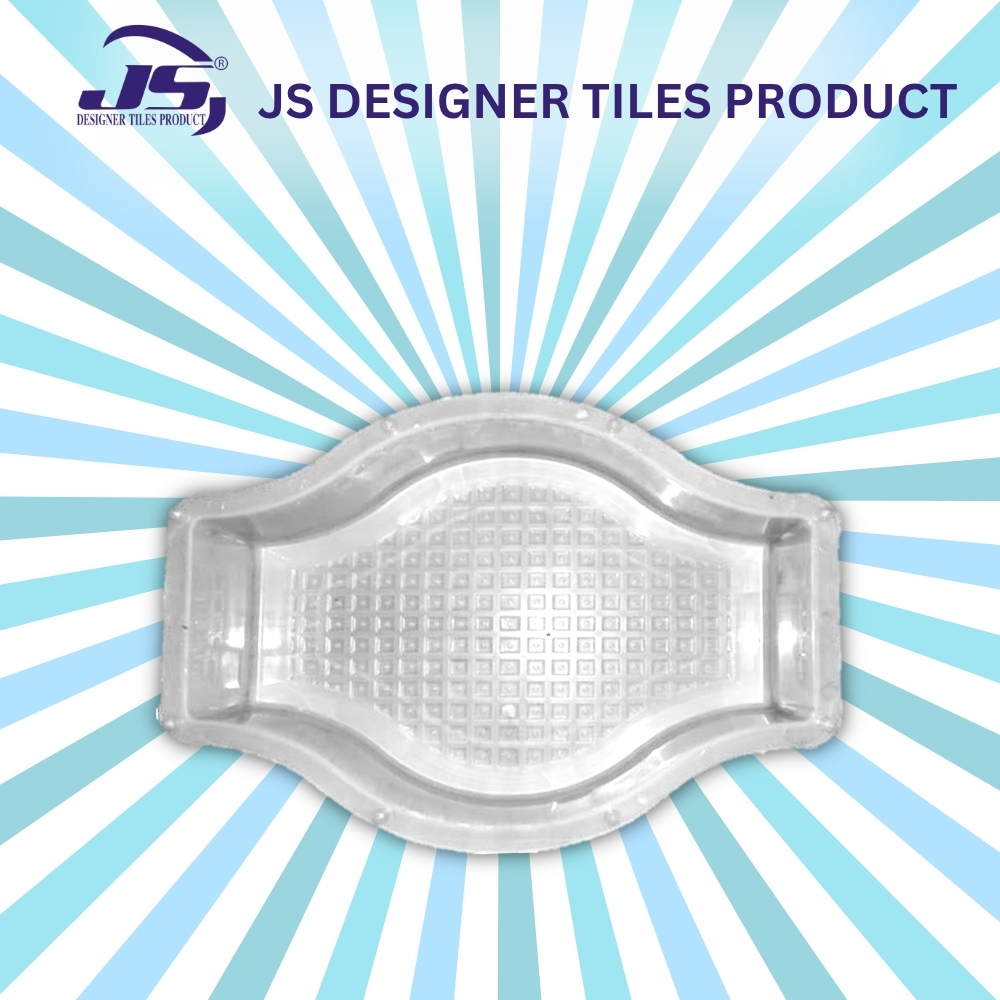

Interlock Block Moulds

Price 41 INR/ Piece

MOQ : 500 Pieces

Interlock Block Moulds Specification

- Molding Material

- SYNTHETIC SILICONE PLASTIC

- Usage

- Making Paver Block

- Material

- Silicone

- Product Type

- PAVING BLOCK MOULDS

- Mould Life

- 1-2 Years

- Color

- Grey and Red

Interlock Block Moulds Trade Information

- Minimum Order Quantity

- 500 Pieces

- Delivery Time

- Days

- Main Domestic Market

- All India

About Interlock Block Moulds

Interlock Block Moulds

Js Designer Tiles Product Is A Leading Manufacturer Of Synthetic Silicone Plastic Mould, Synthetic Silicone Rubber Mold, Paver Block Making Machine, Spray Lacquer Polish, Sponge Lacquer Polish, Iron Oxide Etc.

Premium Silicone Moulds for Lasting Performance

Manufactured with advanced synthetic silicone plastic, our interlock block moulds are engineered to deliver outstanding durability and flexibility. Their resilient design withstands repeated use, making them well-suited for large-scale paver block production and frequent casting cycles.

Versatile Colour Options for Distinctive Pavers

Available in both grey and red, these moulds not only offer practical benefits but also add aesthetic versatility to your paver block designs. The color distinction helps in easy identification and creative block arrangement during landscaping projects.

Precision Engineering for Reliable Results

Each mould is designed for accurate interlocking, ensuring that the paver blocks fit perfectly together. This attention to detail helps improve the structural integrity and visual appeal of finished pavements, driveways, and walkways.

FAQs of Interlock Block Moulds:

Q: How are these interlock block moulds used for making paver blocks?

A: These moulds are filled with a suitable paver block mixture, such as concrete, and left to set. Once cured, the flexible synthetic silicone plastic allows easy removal of the paver blocks without damaging their shape, ensuring a smooth and efficient production process.Q: What materials are the interlock block moulds made from?

A: Our interlock block moulds are constructed from synthetic silicone plastic, which provides both durability and flexibility. This material is ideal for repeatedly casting paver blocks, as it resists wear and deformation over time.Q: When should I replace the silicone paver block moulds?

A: The average mould life is between 1 to 2 years, depending on frequency of use and handling conditions. It is advisable to monitor the moulds for any signs of cracking, loss of flexibility, or deformation and replace them promptly to maintain quality output.Q: Where can these interlock block moulds be utilised?

A: These moulds are mainly used in paver block manufacturing units, landscaping businesses, and construction projects across India and abroad. They are suitable for producing blocks used in walkways, pavements, and driveways.Q: What is the benefit of using silicone moulds over other materials?

A: Silicone moulds provide excellent flexibility, making demoulding simple and reducing the risk of damage to the blocks. They also offer longer life and consistent performance compared to traditional mould materials, resulting in uniform and professional-quality pavers.Q: How does the color of the mould (grey or red) affect its use?

A: The color options primarily aid in identification and sorting during the production process. Grey and red moulds perform equally well, allowing users to organize their moulds for different designs or batches efficiently.Q: What is the process of exporting these moulds from India?

A: As a leading exporter, we handle the logistics, quality checks, and documentation required for international shipments. Customers can contact us directly to discuss quantities, shipping options, and destination requirements for smooth delivery worldwide.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in CONCRETE BLOCK MOULDS Category

HEXAGON KIDA MOULD

Price 41 INR / Piece

Minimum Order Quantity : 500 Pieces

Molding Material : SYNTHETIC SILICONE PLASTIC

Material : Other, Premium Grade Metal & Plastic

Mould Life : 12 Years

Color : Gray & Blue

Interlocking Paver Moulds

Price 42 INR / Piece

Minimum Order Quantity : 500 Pieces

Molding Material : SYNTHETIC SILICONE PLASTIC

Material : Plastic

Mould Life : 12 Years

Color : Gray & Orange

MATKA MOULD

Price 43 INR / Piece

Minimum Order Quantity : 500 Pieces

Molding Material : SYNTHETIC SILICONE PLASTIC

Material : Other, Silicone

Mould Life : 12 Years

Color : Gray & Red

New Cosmic Mould

Price 42 INR / Piece

Minimum Order Quantity : 100 Pieces

Molding Material : SYNTHETIC SILICONE PLASTIC

Material : Plastic

Mould Life : 12 Years

Color : Gray & Red

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS