- Home Page

- Company Profile

-

Our Products

- CHEMICAL HARDENER

- CHEQUERED TILES MOULD

- COLOR MIXING MACHINE

- CONCRETE BLOCK MOULDS

- HEXAGON KIDA MOULD

- Double Zigzag Mould

- GRASS GRID MOULD

- Milano Paver Block Moulds

- GRASS PAVER MOULD

- L-SHAPE MOULD

- Kaju Katli Paving Block Mould

- MATKA MOULD

- Kida Brooks Mould

- Interlocking Concrete Block Moulds

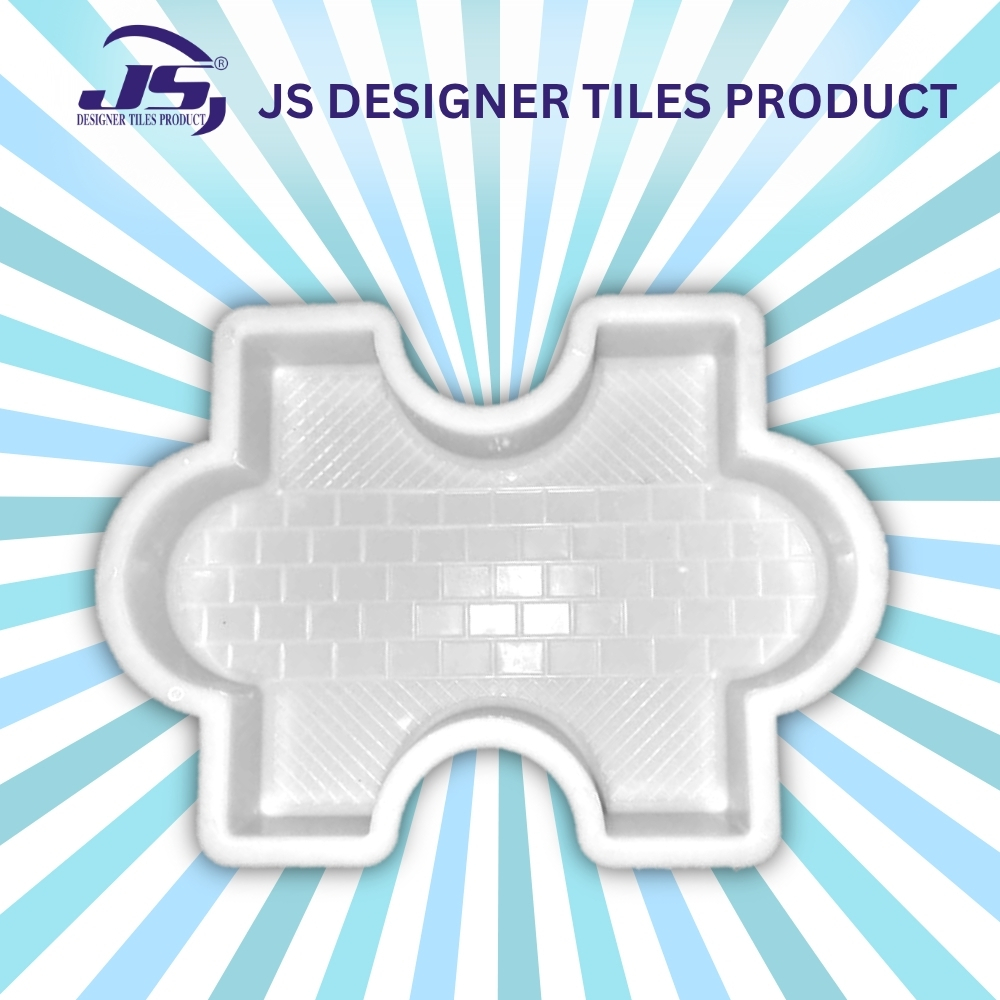

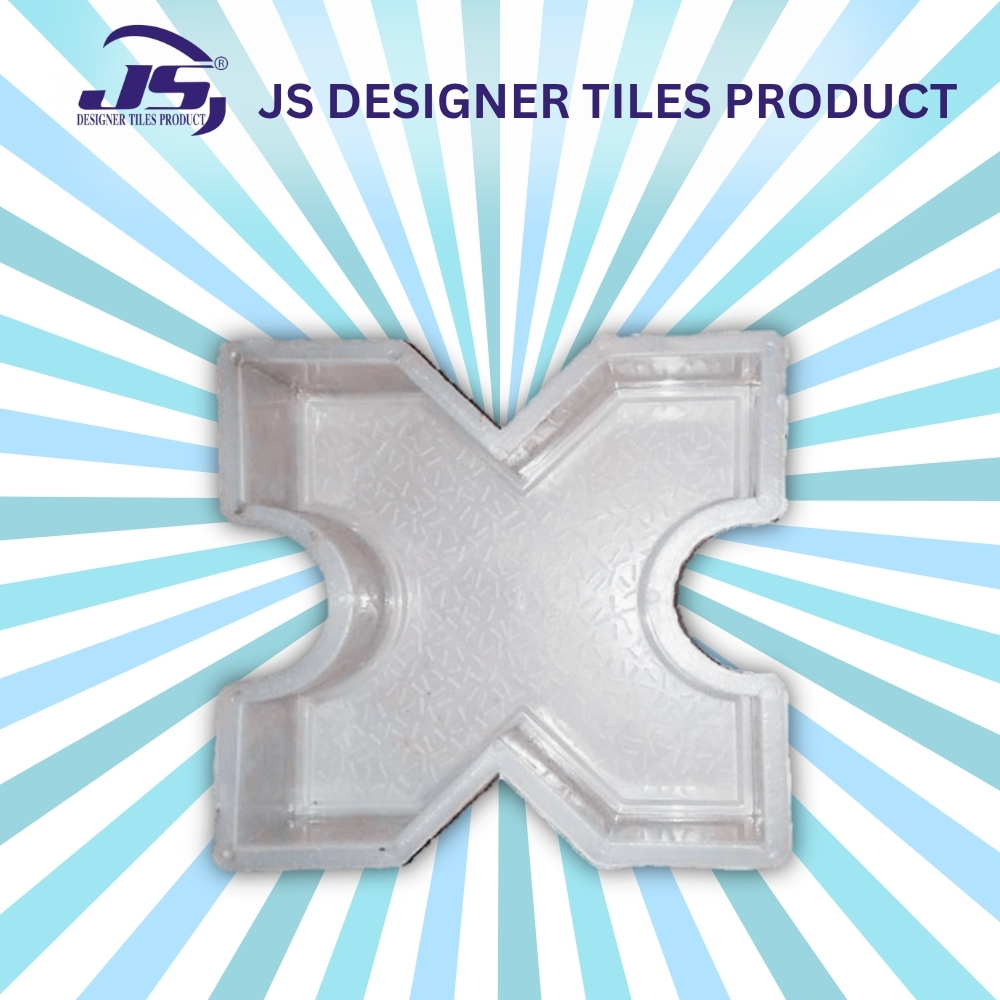

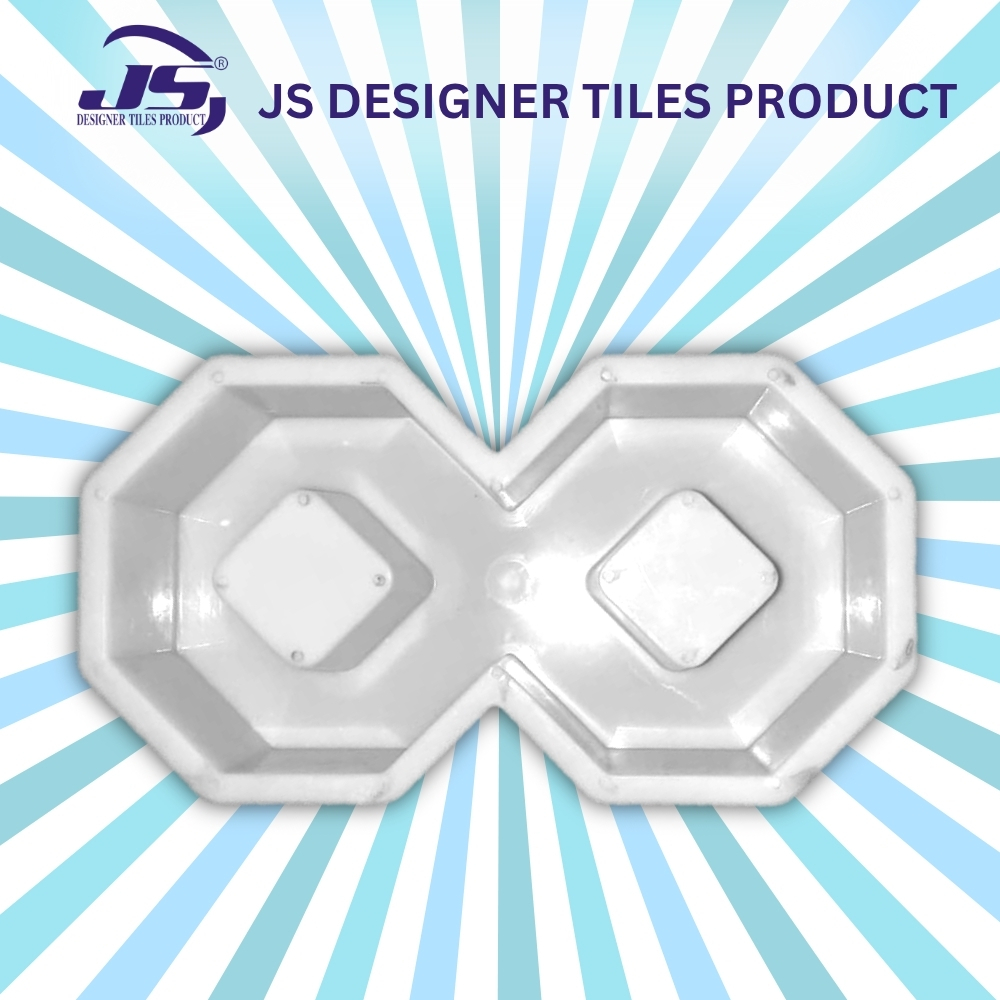

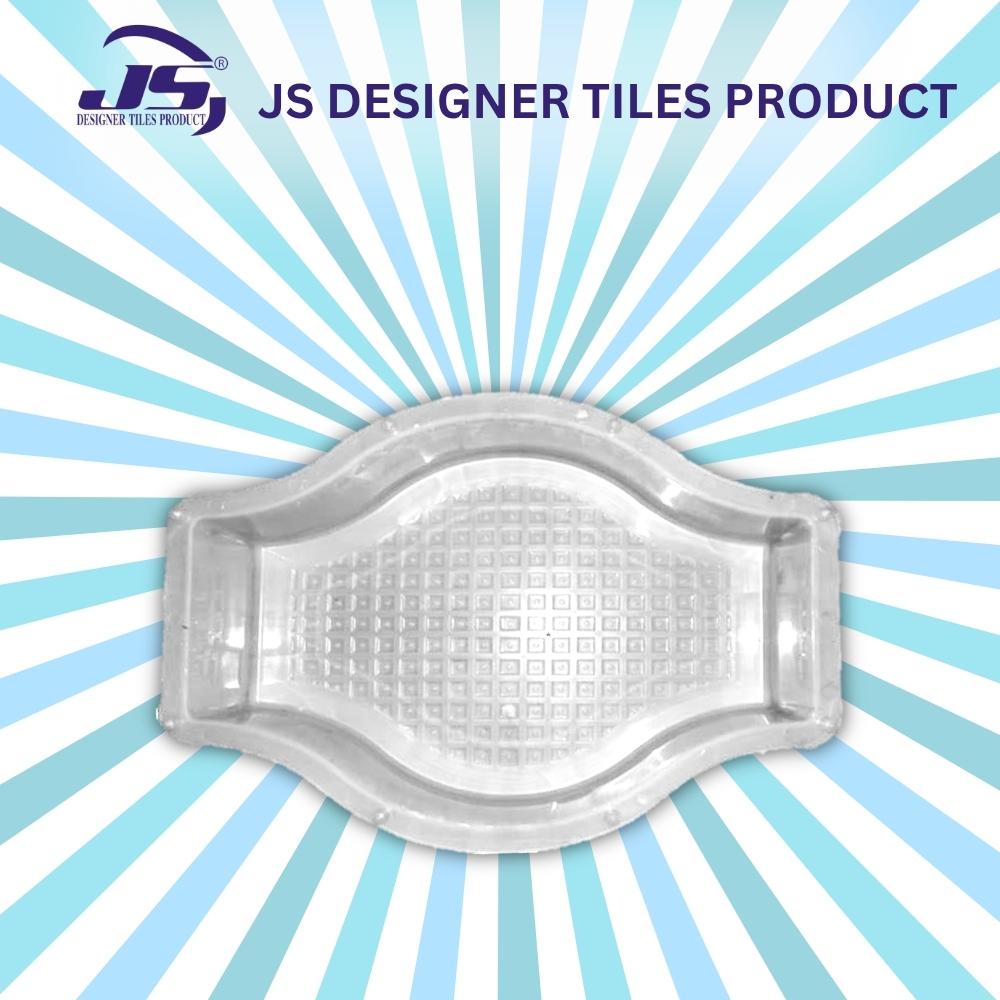

- Interlocking Paver Moulds

- Mould For Paver Block

- Interlock Block Moulds

- New Damru Mould

- New Cosmic Mould

- CONCRETE CHEMICAL

- CONCRETE HARDENER

- CONCRETE MIXER

- COVER BLOCK MOULDS

- Round Cover Block Mould

- 64 Cavity Pvc Cover Block Mould

- 20,25,30mm 64 Cavity Cover Block Mould

- Multy Cavity Cover Block Mould

- Cover Block Rubber Moulds

- RUBBER COVER BLOCK MOULD

- Square Cover Block Mould

- Concrete Cover Block Moulds

- Cover Block Mould In 20, 25, 40, 50.mm

- 42 Cavity Pvc Cover Block Mould

- Rcc Cover Block Mould

- Cover Block Moulds

- Pvc Cover Block Mould

- Cover Block Moulds Manufacture

- SPACERS RUBBER MOULD

- 49 Cavity Rubber Cover Block Mould

- Cover Block Mould Supplier

- Cover Block Mould 20 & 25.mm

- DESIGNER TILES MOULD

- FLOOR TILES MOULD

- HARDENER MAKING MACHINE

- Paver Block Hardener Making Machine

- Concrete Block Hardener Making Machine

- Hardener Machine

- Interlocking Hardener Machinery

- Interlocking Tile Hardener Making Machine

- Block Hardener Making Machine

- Chemical Hardener Making Machine

- Concrete Hardener Making Machine

- Cover Block Hardener Making Machine

- Designer Tile Hardener Making Machine

- Hardener Making Machine

- Interlocking Block Hardener Making Machine

- Paver Block Clean Mould Releasing Chemical Making Machine

- Paver Chemical Hardener Making Machine

- Paver Hardener Machinery

- Paving Block Hardener Machine

- Rmc Admixtures Chemical Making Machine

- Tile Hardener Chemical Making Machine

- Tile Hardener Making Machine

- CONCRETE ADMIXTURE MAKING MACHINE

- CHEQUERED TILE HARDENER MAKING MACHINE

- INTERLOCKING BLOCK MAKING MACHINE

- INTERLOCKING TILE MAKING MACHINE

- IRON OXIDE PIGMENT

- KERB STONE MOULDS

- LACQUER POLISH MAKING MACHINE

- Interlocking Block Lacquer Polish Making Machine

- Floor Paint And Floor Coat Making Machine

- Paving Block Lacquer Polish Making Machine

- Interlocking Tile Lacquer Polish Making Machine

- Paver Lacquer Making Machine

- Chequered Tiles High Gloss Lacquer Coating Making Machine

- Designer Tile Lacquer Polish Making Machine

- Lacquer Coating Making Machine

- Lacquer Polish Machine

- Lacquer Polish Making Machine

- Lacquer Sealer Making Machine

- Lacquer Shiner Making Machine

- Paver Block High Gloss Lacquer Polish Making Machine

- Paver Block Lacquer Polish Making Machine

- Tile Coating Machine

- Tile Lacquer Polish Making Machine

- Top Coat Lacquer Making Machine

- Water Base Lacquer Coating Making Machine

- Block Lacquer Polish Making Machine

- Water Proofing Coating Making Machine

- MANUAL BLOCK MAKING MACHINE

- PAVER BLOCK DEMOULDING MACHINE

- PAVER BLOCK HARDENER

- PAVER BLOCK LACQUER POLISH

- LACQUER COATING FOR PAVER BLOCKS

- TILE LACQUER POLISH

- HIGH GLOSS LACQUER COATING

- ACRYLIC COATINGS

- ACRYLIC LACQUER

- TOP COAT PAVER BLOCK LACQUER

- PAVER BLOCK SHINER

- TILE POLISH

- LACQUER PAINTS

- LIQUID POLISH FOR PAVING BRICKS

- PAVER BLOCK LACQUER COATING

- WATER PROOFING COATING CHEMICAL

- PAVER SEALER

- PAVER COATING LACQUER

- LACQUER COATING

- PAVER LACQUER

- LACQUER POLISH FOR PAVER BLOCKS

- INTERLOCKING TILES POLISH

- LACQUER POLISH

- PAVER BLOCK LACQUER

- LACQUER COLOR COATING CHEMICAL

- HIGH GLOSS LACQUER POLISH

- INTERLOCKING TILE LACQUER POLISH

- PAVER BLOCK PAINT

- NATURAL LACQUER POLISH

- FLOOR PAINT SPECIAL IN PAVER BLOCK & CHEQUERED TILE

- FLOOR PAINT FOR CHEQUERED TILE

- COLOR COATING FOR PAVER BLOCK

- PAVER BLOCK MACHINERY

- PAVER BLOCK MAKING MACHINE

- PAVING BLOCK MOULDS

- SOUTH SET MOULD

- PRECAST PAVER MOULDS

- SILICONE PAVER MOULDS

- ZIG ZAG PAVER MOULD

- V-SHAPE MOULD

- S-SHAPE MOULD

- PAVER BLOCK FARMA

- STAR MOULD

- PAVING BRICK MOULDS

- TRIHEX MOULD

- NEW HEXAGON MOULD

- PAVER BLOCK MOULD

- SQUARE PAVER MOULDS

- PISTON MOULD

- PAVING BLOCK MOULDS

- PAVER MOULDS

- Cement Concrete Tile Lacquer polish making machine

- PVC MOULDS

- PVC PAVER MOULDS

- Pan Mixer Machine

- Color Pan Mixer Machine

- Heavy Duty Pan Mixer Machine

- Paver Block Pan Mixer Machine

- Interlocking Tile Pan Mixer

- PAN MIXER

- Top Layer Pan Mixer

- Top Color Layer Pan Mixer

- Ring Pan Mixer

- Color Pan Mixer

- Paver Block Pan Mixer

- Pan Mixer Machine

- Pan Mixer Machine For Interlocking Tile

- Ring Pan Mixer Machine

- Top Layer Pan Mixer Machine

- RUBBER MOULDS PAVER

- SUPERPLASTICIZER ADMIXTURE

- TILE HARDENER

- TILE MAKING MACHINE

- VIBRATING TABLE

- Designer Vibro Forming

- Heavy Duty Vibro Forming Table

- Paver Designer Tiles Vibro Forming Table

- Vibrator Machine For Paver Block

- Construction Vibro Forming Machine

- Interlocking Block Vibro Forming Machine

- Designer Tile Vibro Forming Table

- Concrete Block Vibro Forming Table

- Designer Tiles Vibro Forming Table

- Interlocking Tile Vibro Forming Machine

- Paver Block Vibro Forming Machine

- VIBRO FORMING MACHINE

- Construction Vibrating Table

- Interlock Vibrating Machine

- HEAVY DUTY VIBRO FORMING TABLE

- PAVER TILE VIBRATING TABLE

- Paver Block Vibrating Table

- Vibro Forming Machine

- Vibro Forming Table Standard

- Tile Vibro Forming Machine

- Vibrating Table Concrete Moulds

- Vibro Table Paver Block Making Machine

- VIBRATING TABLE FOR CONCRETE

- VIBRO FORMING TABLE

- Contact Us

Interlocking Paver Moulds

Price 42 INR/ Piece

MOQ : 500 Pieces

Interlocking Paver Moulds Specification

- Molding Material

- SYNTHETIC SILICONE PLASTIC

- Usage

- MAKING PAVER BLOCKS

- Material

- Plastic

- Product Type

- PAVING BLOCK MOULDS

- Mould Life

- 1-2 Years

- Color

- Gray & Orange

Interlocking Paver Moulds Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- Days

- Main Domestic Market

- All India

About Interlocking Paver Moulds

Interlocking Paver Moulds

JS DESIGNER TILES PRODUCT is a leading manufacturer of Synthetic Silicone Plastic Mould, Synthetic Silicone Rubber Mold, Paver Block Making Machine, Spray Lacquer Polish, Sponge Lacquer Polish, Iron Oxide etc.

Durable Material and Design

Manufactured using synthetic silicone plastic, these interlocking paver moulds offer significant durability and a flexible, user-friendly design. Their robust build provides consistent block shapes, while color options (gray and orange) cater to diverse aesthetic preferences. The plastic material resists warping and breakage, making them suitable for repeated use.

Intended Usage and Application

These moulds are intended specifically for producing high-quality interlocking paver blocks. Their design streamlines the block-making process for manufacturers, suppliers, and exporters, catering particularly to the construction and landscaping industries. Their ease of use and efficient operation make them an essential tool in mass paver block production.

Longevity and Maintenance

With a typical mould life of 1-2 years, these plastic moulds offer an optimal balance between cost and performance. Proper care, cleaning, and adherence to recommended operational guidelines can further extend their usability, maximizing your investment in large-scale paver block manufacturing projects.

FAQs of Interlocking Paver Moulds:

Q: How are interlocking paver moulds used for making paver blocks?

A: To use the moulds, fill them with a concrete mixture and allow proper curing time. Once set, the moulds can be removed to reveal well-formed interlocking paver blocks suitable for outdoor paving projects.Q: What are the main materials used in these paver moulds?

A: These moulds are constructed from synthetic silicone plastic, a blend that ensures flexibility, durability, and the ability to create a smooth finish on paver blocks.Q: When should the moulds be replaced?

A: Under standard manufacturing conditions, the moulds maintain their quality for about 1-2 years. Replacement is recommended if you observe loss of shape, warping, or surface damage impacting block finish.Q: Where are these interlocking paver moulds manufactured and supplied from?

A: The moulds are produced and distributed from India, serving construction firms and block manufacturers globally through a robust network of exporters, manufacturers, and suppliers.Q: What is the process of making paver blocks using these moulds?

A: The typical process involves mixing concrete, pouring it into the moulds, vibrating and settling the mix, curing, and finally demoulding the solidified blocks for use.Q: What advantages do synthetic silicone plastic paver moulds offer?

A: These moulds provide excellent dimensional stability, reusability, ease of cleaning, and help achieve a consistent, professional appearance in mass-produced paver blocks.Q: How should I care for and maintain the moulds to extend their life?

A: After each production cycle, clean the moulds thoroughly and store them in a cool, dry place away from direct sunlight. Regular inspection for wear and proper handling will prolong their lifespan.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in CONCRETE BLOCK MOULDS Category

GRASS PAVER MOULD

Price 47 INR / Piece

Minimum Order Quantity : 500 Pieces

Product Type : PAVING BLOCK MOULDS

Color : Gray

Mould Life : 12 Years

Material : Plastic

GRASS GRID MOULD

Price 125 INR / Piece

Minimum Order Quantity : 500 Pieces

Product Type : PAVING BLOCK MOULDS

Color : Gray

Mould Life : 12 Years

Material : Plastic

Mould For Paver Block

Price 39 INR / Piece

Minimum Order Quantity : 500 Pieces

Product Type : PAVING BLOCK MOULDS

Color : Gray & Yellow

Mould Life : 12 Years

Material : Plastic

Kaju Katli Paving Block Mould

Price 41 INR / Piece

Minimum Order Quantity : 500 Pieces

Product Type : PAVING BLOCK MOULDS

Color : Gray & Yellow

Mould Life : 12 Years

Material : Other, Silicone

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS