- Home Page

- Company Profile

-

Our Products

- CHEMICAL HARDENER

- CHEQUERED TILES MOULD

- COLOR MIXING MACHINE

- CONCRETE BLOCK MOULDS

- HEXAGON KIDA MOULD

- Double Zigzag Mould

- GRASS GRID MOULD

- Milano Paver Block Moulds

- GRASS PAVER MOULD

- L-SHAPE MOULD

- Kaju Katli Paving Block Mould

- MATKA MOULD

- Kida Brooks Mould

- Interlocking Concrete Block Moulds

- Interlocking Paver Moulds

- Mould For Paver Block

- Interlock Block Moulds

- New Damru Mould

- New Cosmic Mould

- CONCRETE CHEMICAL

- CONCRETE HARDENER

- CONCRETE MIXER

- COVER BLOCK MOULDS

- Square Cover Block Mould

- Multy Cavity Cover Block Mould

- 42 Cavity Pvc Cover Block Mould

- Cover Block Rubber Moulds

- Rcc Cover Block Mould

- Pvc Cover Block Mould

- Cover Block Moulds

- Cover Block Mould 20 & 25.mm

- Concrete Cover Block Moulds

- Cover Block Mould In 20, 25, 40, 50.mm

- 49 Cavity Rubber Cover Block Mould

- Cover Block Moulds Manufacture

- SPACERS RUBBER MOULD

- Round Cover Block Mould

- RUBBER COVER BLOCK MOULD

- Cover Block Mould Supplier

- 20,25,30mm 64 Cavity Cover Block Mould

- 64 Cavity Pvc Cover Block Mould

- DESIGNER TILES MOULD

- FLOOR TILES MOULD

- HARDENER MAKING MACHINE

- Paver Block Hardener Making Machine

- Concrete Block Hardener Making Machine

- Hardener Machine

- Interlocking Hardener Machinery

- Interlocking Tile Hardener Making Machine

- Block Hardener Making Machine

- Chemical Hardener Making Machine

- Concrete Hardener Making Machine

- Cover Block Hardener Making Machine

- Designer Tile Hardener Making Machine

- Hardener Making Machine

- Interlocking Block Hardener Making Machine

- Paver Block Clean Mould Releasing Chemical Making Machine

- Paver Chemical Hardener Making Machine

- Paver Hardener Machinery

- Paving Block Hardener Machine

- Rmc Admixtures Chemical Making Machine

- Tile Hardener Chemical Making Machine

- Tile Hardener Making Machine

- CONCRETE ADMIXTURE MAKING MACHINE

- CHEQUERED TILE HARDENER MAKING MACHINE

- INTERLOCKING BLOCK MAKING MACHINE

- INTERLOCKING TILE MAKING MACHINE

- IRON OXIDE PIGMENT

- KERB STONE MOULDS

- LACQUER POLISH MAKING MACHINE

- Interlocking Block Lacquer Polish Making Machine

- Floor Paint And Floor Coat Making Machine

- Paving Block Lacquer Polish Making Machine

- Interlocking Tile Lacquer Polish Making Machine

- Paver Lacquer Making Machine

- Chequered Tiles High Gloss Lacquer Coating Making Machine

- Designer Tile Lacquer Polish Making Machine

- Lacquer Coating Making Machine

- Lacquer Polish Machine

- Lacquer Polish Making Machine

- Lacquer Sealer Making Machine

- Lacquer Shiner Making Machine

- Paver Block High Gloss Lacquer Polish Making Machine

- Paver Block Lacquer Polish Making Machine

- Tile Coating Machine

- Tile Lacquer Polish Making Machine

- Top Coat Lacquer Making Machine

- Water Base Lacquer Coating Making Machine

- Block Lacquer Polish Making Machine

- Water Proofing Coating Making Machine

- MANUAL BLOCK MAKING MACHINE

- PAVER BLOCK DEMOULDING MACHINE

- PAVER BLOCK HARDENER

- PAVER BLOCK LACQUER POLISH

- ACRYLIC COATINGS

- TILE LACQUER POLISH

- HIGH GLOSS LACQUER COATING

- LACQUER COATING FOR PAVER BLOCKS

- PAVER BLOCK SHINER

- TOP COAT PAVER BLOCK LACQUER

- ACRYLIC LACQUER

- TILE POLISH

- LACQUER PAINTS

- LIQUID POLISH FOR PAVING BRICKS

- PAVER SEALER

- PAVER BLOCK LACQUER COATING

- WATER PROOFING COATING CHEMICAL

- PAVER COATING LACQUER

- LACQUER COATING

- PAVER LACQUER

- LACQUER POLISH FOR PAVER BLOCKS

- INTERLOCKING TILES POLISH

- LACQUER POLISH

- LACQUER COLOR COATING CHEMICAL

- PAVER BLOCK LACQUER

- HIGH GLOSS LACQUER POLISH

- INTERLOCKING TILE LACQUER POLISH

- PAVER BLOCK PAINT

- NATURAL LACQUER POLISH

- FLOOR PAINT SPECIAL IN PAVER BLOCK & CHEQUERED TILE

- FLOOR PAINT FOR CHEQUERED TILE

- COLOR COATING FOR PAVER BLOCK

- PAVER BLOCK MACHINERY

- PAVER BLOCK MAKING MACHINE

- PAVING BLOCK MOULDS

- SOUTH SET MOULD

- SILICONE PAVER MOULDS

- ZIG ZAG PAVER MOULD

- V-SHAPE MOULD

- PRECAST PAVER MOULDS

- PAVER BLOCK FARMA

- STAR MOULD

- PAVING BRICK MOULDS

- TRIHEX MOULD

- NEW HEXAGON MOULD

- PAVER BLOCK MOULD

- SQUARE PAVER MOULDS

- PISTON MOULD

- PAVING BLOCK MOULDS

- PAVER MOULDS

- S-SHAPE MOULD

- Cement Concrete Tile Lacquer polish making machine

- PVC MOULDS

- PVC PAVER MOULDS

- Pan Mixer Machine

- Heavy Duty Pan Mixer Machine

- Color Pan Mixer Machine

- Paver Block Pan Mixer Machine

- Interlocking Tile Pan Mixer

- PAN MIXER

- Top Layer Pan Mixer

- Top Color Layer Pan Mixer

- Ring Pan Mixer

- Color Pan Mixer

- Paver Block Pan Mixer

- Pan Mixer Machine

- Pan Mixer Machine For Interlocking Tile

- Ring Pan Mixer Machine

- Top Layer Pan Mixer Machine

- RUBBER MOULDS PAVER

- SUPERPLASTICIZER ADMIXTURE

- TILE HARDENER

- TILE MAKING MACHINE

- VIBRATING TABLE

- Paver Designer Tiles Vibro Forming Table

- Vibrator Machine For Paver Block

- Heavy Duty Vibro Forming Table

- Interlocking Block Vibro Forming Machine

- Construction Vibro Forming Machine

- Designer Vibro Forming

- Designer Tile Vibro Forming Table

- Concrete Block Vibro Forming Table

- Designer Tiles Vibro Forming Table

- Interlocking Tile Vibro Forming Machine

- Paver Block Vibro Forming Machine

- VIBRO FORMING MACHINE

- Paver Block Vibrating Table

- PAVER TILE VIBRATING TABLE

- Interlock Vibrating Machine

- HEAVY DUTY VIBRO FORMING TABLE

- Construction Vibrating Table

- Vibro Forming Machine

- Vibro Forming Table Standard

- Tile Vibro Forming Machine

- Vibrating Table Concrete Moulds

- Vibro Table Paver Block Making Machine

- VIBRATING TABLE FOR CONCRETE

- VIBRO FORMING TABLE

- Contact Us

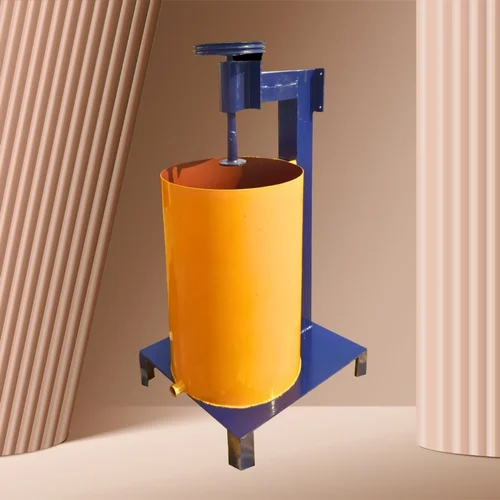

Tile Hardener Chemical Making Machine

Price 120000.00 INR/ Piece

MOQ : 1 Piece

Tile Hardener Chemical Making Machine Specification

- Type

- HARDENER MAKING MACHINE

- Material

- MILD STEEL

- Computerized

- No

- Voltage

- 110-220 Volt (v)

- Color

- Blue

- Warranty

- 1 YEAR

Tile Hardener Chemical Making Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 4-5 Days

- Main Domestic Market

- All India

About Tile Hardener Chemical Making Machine

Tile Hardener Chemical Making Machine

Js Designer Tiles Product Is A Leading Manufacturer Of Synthetic Silicone Plastic Mould, Synthetic Silicone Rubber Mold, Paver Block Making Machine, Spray Lacquer Polish, Sponge Lacquer Polish, Iron Oxide Etc.

Reliable Construction and Materials

This hardener making machine features a sturdy build with high-quality mild steel, ensuring longevity and resistance to wear. Its blue finish not only gives it a professional appearance but also adds to its durability. With a voltage range suitable for Indian power conditions, it fits diverse operational environments.

Efficient Production Capability

Designed for efficiency, this machine allows users to produce tile hardener chemicals in batch quantities with consistency. The non-computerized controls are straightforward, minimizing training requirements and maximizing productivity in both small workshops and large facilities.

FAQs of Tile Hardener Chemical Making Machine:

Q: How does the Tile Hardener Chemical Making Machine operate?

A: This machine functions through a manually controlled process, blending raw materials to produce tile hardener chemicals. Simply load the ingredients, set the required parameters, and initiate the mixing cycle to achieve a consistent product.Q: What materials is the machine made from and why?

A: The machine is constructed from mild steel, which provides excellent strength, durability, and resistance to corrosion, making it ideal for heavy-duty industrial use.Q: When can I expect delivery of the machine in India?

A: Delivery times vary based on location and order volume, but as the machine is available from manufacturers, exporters, and suppliers within India, most customers can expect delivery within 2 to 4 weeks.Q: Where can the Tile Hardener Chemical Making Machine be used?

A: This machine is suitable for use in manufacturing units, tile production plants, and industrial facilities across India that need reliable and efficient production of tile hardener chemicals.Q: What is the process of making tile hardener chemicals with this machine?

A: The process involves adding measured raw materials into the mixing chamber, setting manual controls, and allowing the machine to blend the components into a homogeneous hardener chemical solution.Q: How is the machine maintained for optimal usage?

A: Routine cleaning and inspection of moving parts is recommended. As it is not computerized, mechanical maintenance is straightforward with parts being easily accessible for servicing.Q: What are the benefits of choosing this hardener making machine?

A: Users benefit from its robust construction, operational simplicity, flexible voltage support, and comprehensive 1-year warranty, all contributing to enhanced productivity and long-term reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in HARDENER MAKING MACHINE Category

Rmc Admixtures Chemical Making Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 YEAR

Voltage : 110220 Volt (v)

Material : MILD STEEL

Color : Bronze

Tile Hardener Making Machine

Price 120000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 YEAR

Voltage : 110220 Volt (v)

Material : MILD STEEL

Color : White

Concrete Block Hardener Making Machine

Price 120000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 YEAR

Voltage : 110220 Volt (v)

Material : MILD STEEL

Color : Blue

Cover Block Hardener Making Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 YEAR

Voltage : 110220 Volt (v)

Material : MILD STEEL

Color : Brown

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free