- Home Page

- Company Profile

-

Our Products

- CHEMICAL HARDENER

- CHEQUERED TILES MOULD

- COLOR MIXING MACHINE

- CONCRETE BLOCK MOULDS

- HEXAGON KIDA MOULD

- Kida Brooks Mould

- Mould For Paver Block

- Interlocking Paver Moulds

- Interlock Block Moulds

- Interlocking Concrete Block Moulds

- Double Zigzag Mould

- GRASS GRID MOULD

- Milano Paver Block Moulds

- GRASS PAVER MOULD

- L-SHAPE MOULD

- Kaju Katli Paving Block Mould

- MATKA MOULD

- New Damru Mould

- New Cosmic Mould

- CONCRETE CHEMICAL

- CONCRETE HARDENER

- CONCRETE MIXER

- COVER BLOCK MOULDS

- SPACERS RUBBER MOULD

- Concrete Cover Block Moulds

- Cover Block Moulds Manufacture

- Cover Block Mould In 20, 25, 40, 50.mm

- Cover Block Mould 20 & 25.mm

- 42 Cavity Pvc Cover Block Mould

- 20,25,30mm 64 Cavity Cover Block Mould

- Multy Cavity Cover Block Mould

- Cover Block Rubber Moulds

- RUBBER COVER BLOCK MOULD

- 49 Cavity Rubber Cover Block Mould

- Rcc Cover Block Mould

- Round Cover Block Mould

- Square Cover Block Mould

- Cover Block Mould Supplier

- Pvc Cover Block Mould

- 64 Cavity Pvc Cover Block Mould

- Cover Block Moulds

- DESIGNER TILES MOULD

- FLOOR TILES MOULD

- HARDENER MAKING MACHINE

- Paver Block Hardener Making Machine

- Concrete Block Hardener Making Machine

- Hardener Machine

- Interlocking Hardener Machinery

- Interlocking Tile Hardener Making Machine

- Block Hardener Making Machine

- Chemical Hardener Making Machine

- Concrete Hardener Making Machine

- Cover Block Hardener Making Machine

- Designer Tile Hardener Making Machine

- Hardener Making Machine

- Interlocking Block Hardener Making Machine

- Paver Block Clean Mould Releasing Chemical Making Machine

- Paver Chemical Hardener Making Machine

- Paver Hardener Machinery

- Paving Block Hardener Machine

- Rmc Admixtures Chemical Making Machine

- Tile Hardener Chemical Making Machine

- Tile Hardener Making Machine

- CONCRETE ADMIXTURE MAKING MACHINE

- CHEQUERED TILE HARDENER MAKING MACHINE

- INTERLOCKING BLOCK MAKING MACHINE

- INTERLOCKING TILE MAKING MACHINE

- IRON OXIDE PIGMENT

- KERB STONE MOULDS

- LACQUER POLISH MAKING MACHINE

- Interlocking Block Lacquer Polish Making Machine

- Floor Paint And Floor Coat Making Machine

- Paving Block Lacquer Polish Making Machine

- Interlocking Tile Lacquer Polish Making Machine

- Paver Lacquer Making Machine

- Chequered Tiles High Gloss Lacquer Coating Making Machine

- Designer Tile Lacquer Polish Making Machine

- Lacquer Coating Making Machine

- Lacquer Polish Machine

- Lacquer Polish Making Machine

- Lacquer Sealer Making Machine

- Lacquer Shiner Making Machine

- Paver Block High Gloss Lacquer Polish Making Machine

- Paver Block Lacquer Polish Making Machine

- Tile Coating Machine

- Tile Lacquer Polish Making Machine

- Top Coat Lacquer Making Machine

- Water Base Lacquer Coating Making Machine

- Block Lacquer Polish Making Machine

- Water Proofing Coating Making Machine

- MANUAL BLOCK MAKING MACHINE

- PAVER BLOCK DEMOULDING MACHINE

- PAVER BLOCK HARDENER

- PAVER BLOCK LACQUER POLISH

- LACQUER COATING FOR PAVER BLOCKS

- HIGH GLOSS LACQUER COATING

- ACRYLIC COATINGS

- TILE LACQUER POLISH

- PAVER BLOCK SHINER

- TOP COAT PAVER BLOCK LACQUER

- ACRYLIC LACQUER

- LIQUID POLISH FOR PAVING BRICKS

- TILE POLISH

- LACQUER PAINTS

- WATER PROOFING COATING CHEMICAL

- PAVER SEALER

- PAVER BLOCK LACQUER COATING

- PAVER COATING LACQUER

- LACQUER COATING

- PAVER LACQUER

- LACQUER POLISH FOR PAVER BLOCKS

- INTERLOCKING TILES POLISH

- LACQUER POLISH

- PAVER BLOCK LACQUER

- LACQUER COLOR COATING CHEMICAL

- HIGH GLOSS LACQUER POLISH

- INTERLOCKING TILE LACQUER POLISH

- PAVER BLOCK PAINT

- NATURAL LACQUER POLISH

- FLOOR PAINT SPECIAL IN PAVER BLOCK & CHEQUERED TILE

- FLOOR PAINT FOR CHEQUERED TILE

- COLOR COATING FOR PAVER BLOCK

- PAVER BLOCK MACHINERY

- PAVER BLOCK MAKING MACHINE

- PAVING BLOCK MOULDS

- ZIG ZAG PAVER MOULD

- V-SHAPE MOULD

- S-SHAPE MOULD

- PAVER BLOCK MOULD

- PAVER BLOCK FARMA

- STAR MOULD

- TRIHEX MOULD

- SQUARE PAVER MOULDS

- SOUTH SET MOULD

- SILICONE PAVER MOULDS

- PRECAST PAVER MOULDS

- NEW HEXAGON MOULD

- PISTON MOULD

- PAVER MOULDS

- PAVING BRICK MOULDS

- PAVING BLOCK MOULDS

- Cement Concrete Tile Lacquer polish making machine

- PVC MOULDS

- PVC PAVER MOULDS

- Pan Mixer Machine

- Paver Block Pan Mixer Machine

- Color Pan Mixer Machine

- Heavy Duty Pan Mixer Machine

- Interlocking Tile Pan Mixer

- PAN MIXER

- Top Layer Pan Mixer

- Top Color Layer Pan Mixer

- Ring Pan Mixer

- Color Pan Mixer

- Paver Block Pan Mixer

- Pan Mixer Machine

- Pan Mixer Machine For Interlocking Tile

- Ring Pan Mixer Machine

- Top Layer Pan Mixer Machine

- RUBBER MOULDS PAVER

- SUPERPLASTICIZER ADMIXTURE

- TILE HARDENER

- TILE MAKING MACHINE

- VIBRATING TABLE

- Designer Vibro Forming

- Construction Vibro Forming Machine

- Designer Tile Vibro Forming Table

- Vibrator Machine For Paver Block

- Interlocking Block Vibro Forming Machine

- Heavy Duty Vibro Forming Table

- Paver Designer Tiles Vibro Forming Table

- Concrete Block Vibro Forming Table

- Designer Tiles Vibro Forming Table

- Interlocking Tile Vibro Forming Machine

- Paver Block Vibro Forming Machine

- VIBRO FORMING MACHINE

- PAVER TILE VIBRATING TABLE

- Construction Vibrating Table

- Interlock Vibrating Machine

- HEAVY DUTY VIBRO FORMING TABLE

- Paver Block Vibrating Table

- Vibro Forming Machine

- Vibro Forming Table Standard

- Tile Vibro Forming Machine

- Vibrating Table Concrete Moulds

- Vibro Table Paver Block Making Machine

- VIBRATING TABLE FOR CONCRETE

- VIBRO FORMING TABLE

- Contact Us

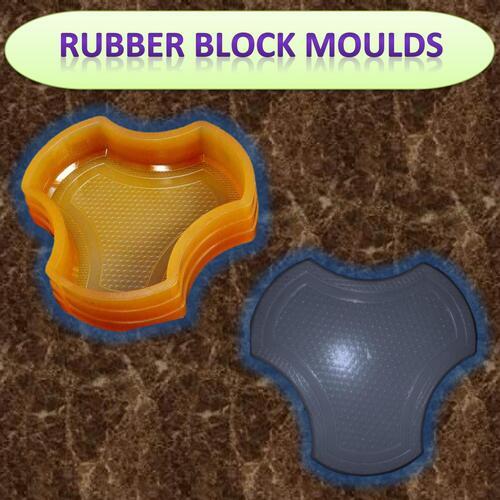

RUBBER BLOCK MOULDS

Price 176 INR/ Piece

MOQ : 100 Kilograms

RUBBER BLOCK MOULDS Specification

- Molding Material

- SYNTHETIC SILICONE RUBBER

- Mold Base

- Stainless Steel

- Cavity

- Multi Cavity

- Life Span

- 5-6 years

- Usage

- MAKING PAVER BLOCKS

- Shaping Mode

- Compression Mould

- Material

- Rubber

- Tolerance

- 0.05 mm

- Product Type

- RUBBER BLOCK MOULDS

- Mould Weight

- 14 Kg (approx)

- Mould Life

- 5-6 Years

- Feature

- Reusable, Durable, High Precision

- Shape

- Custom Block Shape

- Dimensions

- As per design

- Operating Temperature

- -20°C to 180°C

- Hardness

- 45-60 Shore A

- Surface Finish

- Smooth & Textured Available

- Color

- Black or Customizable

RUBBER BLOCK MOULDS Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Average Load Time

- 35-60 seconds

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 4-5 Days

- Main Domestic Market

- All India

About RUBBER BLOCK MOULDS

JS DESIGNER TILES PRODUCT is a leading manufacturer of Synthetic Silicone Plastic Mould, Synthetic Silicone Rubber Mold, Paver Block Making Machine, Spray Lacquer Polish, Sponge Lacquer Polish, Iron Oxide etc.

Product details

|

Minimum Order Quantity |

100 Unit |

|

Thickness |

12-50mm |

|

Shape |

HEXAGON |

|

I Deal In |

New Only |

|

Color |

Orange |

|

Brand |

JS |

|

Material |

Rubber |

|

Usage/Application |

Making Paver Block |

|

Country of Origin |

Made in India |

Exceptional Durability and Reusability

Designed with synthetic silicone rubber and stainless steel bases, our rubber block moulds maintain their structural integrity under frequent use. With an estimated lifespan of 5-6 years and high resistance to wear, they stand up to intensive production schedules, ensuring reliable outputs and cost-effectiveness.

Precise Surface Finishes and Customization

Available with both smooth and textured finishes, these moulds support customized designs, shapes, and colors tailored to specific architectural or landscaping projects. Their high precision, with tolerances as tight as 0.05 mm, guarantees consistent, professional-grade block outputs every time.

FAQs of RUBBER BLOCK MOULDS:

Q: How are these rubber block moulds used for making paver blocks?

A: These moulds are primarily used in the compression moulding process for fabricating paver blocks. The silicone rubber forms the desired shape, while the multi-cavity and high-precision engineering ensure multiple blocks can be produced simultaneously with consistent quality.Q: What benefits do rubber block moulds offer compared to traditional moulds?

A: Rubber block moulds provide superior surface finishes, enhanced durability, and excellent reusability. Their precise engineering minimizes material wastage and ensures uniformity in block size and texture, resulting in increased efficiency and cost savings for manufacturers.Q: When should I consider replacing my rubber block moulds?

A: With a typical lifespan of 5-6 years under standard operating conditions, these moulds should be replaced if you notice significant wear, distortion, or a decline in finished block quality. Regular inspection ensures optimal performance throughout their usage.Q: Where are these rubber block moulds manufactured and supplied from?

A: These moulds are manufactured, supplied, and exported from India by experienced manufacturers, offering both standard and customized solutions for domestic and international clients.Q: What is the process for ordering customized shapes or sizes in these moulds?

A: To order customized shapes or dimensions, you can provide your specifications to the supplier. The moulds are then designed and fabricated as per your unique requirements, ensuring the finished blocks meet your design standards.Q: What temperature range can these synthetic silicone rubber moulds withstand during operation?

A: These moulds are designed to withstand temperatures ranging from -20C to 180C, making them suitable for a wide range of workplace environments and curing processes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in RUBBER MOULDS PAVER Category

RUBBER MOULDS PAVER

Price 176 INR / Piece

Minimum Order Quantity : 100 Kilograms

Material : Rubber

Mold Base : Highgrade steel or aluminum frame

Molding Material : SYNTHETIC SILICONE RUBBER

Usage : MAKING PAVER BLOCKS

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free