- Home Page

- Company Profile

-

Our Products

- CHEMICAL HARDENER

- CHEQUERED TILES MOULD

- COLOR MIXING MACHINE

- CONCRETE BLOCK MOULDS

- HEXAGON KIDA MOULD

- Double Zigzag Mould

- GRASS GRID MOULD

- Milano Paver Block Moulds

- GRASS PAVER MOULD

- L-SHAPE MOULD

- Kaju Katli Paving Block Mould

- MATKA MOULD

- Kida Brooks Mould

- Interlocking Concrete Block Moulds

- Interlocking Paver Moulds

- Mould For Paver Block

- Interlock Block Moulds

- New Damru Mould

- New Cosmic Mould

- CONCRETE CHEMICAL

- CONCRETE HARDENER

- CONCRETE MIXER

- COVER BLOCK MOULDS

- Round Cover Block Mould

- 64 Cavity Pvc Cover Block Mould

- 20,25,30mm 64 Cavity Cover Block Mould

- Multy Cavity Cover Block Mould

- Cover Block Rubber Moulds

- RUBBER COVER BLOCK MOULD

- Square Cover Block Mould

- Concrete Cover Block Moulds

- Cover Block Mould In 20, 25, 40, 50.mm

- 42 Cavity Pvc Cover Block Mould

- Rcc Cover Block Mould

- Cover Block Moulds

- Pvc Cover Block Mould

- Cover Block Moulds Manufacture

- SPACERS RUBBER MOULD

- 49 Cavity Rubber Cover Block Mould

- Cover Block Mould Supplier

- Cover Block Mould 20 & 25.mm

- DESIGNER TILES MOULD

- FLOOR TILES MOULD

- HARDENER MAKING MACHINE

- Paver Block Hardener Making Machine

- Concrete Block Hardener Making Machine

- Hardener Machine

- Interlocking Hardener Machinery

- Interlocking Tile Hardener Making Machine

- Block Hardener Making Machine

- Chemical Hardener Making Machine

- Concrete Hardener Making Machine

- Cover Block Hardener Making Machine

- Designer Tile Hardener Making Machine

- Hardener Making Machine

- Interlocking Block Hardener Making Machine

- Paver Block Clean Mould Releasing Chemical Making Machine

- Paver Chemical Hardener Making Machine

- Paver Hardener Machinery

- Paving Block Hardener Machine

- Rmc Admixtures Chemical Making Machine

- Tile Hardener Chemical Making Machine

- Tile Hardener Making Machine

- CONCRETE ADMIXTURE MAKING MACHINE

- CHEQUERED TILE HARDENER MAKING MACHINE

- INTERLOCKING BLOCK MAKING MACHINE

- INTERLOCKING TILE MAKING MACHINE

- IRON OXIDE PIGMENT

- KERB STONE MOULDS

- LACQUER POLISH MAKING MACHINE

- Interlocking Block Lacquer Polish Making Machine

- Floor Paint And Floor Coat Making Machine

- Paving Block Lacquer Polish Making Machine

- Interlocking Tile Lacquer Polish Making Machine

- Paver Lacquer Making Machine

- Chequered Tiles High Gloss Lacquer Coating Making Machine

- Designer Tile Lacquer Polish Making Machine

- Lacquer Coating Making Machine

- Lacquer Polish Machine

- Lacquer Polish Making Machine

- Lacquer Sealer Making Machine

- Lacquer Shiner Making Machine

- Paver Block High Gloss Lacquer Polish Making Machine

- Paver Block Lacquer Polish Making Machine

- Tile Coating Machine

- Tile Lacquer Polish Making Machine

- Top Coat Lacquer Making Machine

- Water Base Lacquer Coating Making Machine

- Block Lacquer Polish Making Machine

- Water Proofing Coating Making Machine

- MANUAL BLOCK MAKING MACHINE

- PAVER BLOCK DEMOULDING MACHINE

- PAVER BLOCK HARDENER

- PAVER BLOCK LACQUER POLISH

- LACQUER COATING FOR PAVER BLOCKS

- TILE LACQUER POLISH

- HIGH GLOSS LACQUER COATING

- ACRYLIC COATINGS

- ACRYLIC LACQUER

- TOP COAT PAVER BLOCK LACQUER

- PAVER BLOCK SHINER

- TILE POLISH

- LACQUER PAINTS

- LIQUID POLISH FOR PAVING BRICKS

- PAVER BLOCK LACQUER COATING

- WATER PROOFING COATING CHEMICAL

- PAVER SEALER

- PAVER COATING LACQUER

- LACQUER COATING

- PAVER LACQUER

- LACQUER POLISH FOR PAVER BLOCKS

- INTERLOCKING TILES POLISH

- LACQUER POLISH

- PAVER BLOCK LACQUER

- LACQUER COLOR COATING CHEMICAL

- HIGH GLOSS LACQUER POLISH

- INTERLOCKING TILE LACQUER POLISH

- PAVER BLOCK PAINT

- NATURAL LACQUER POLISH

- FLOOR PAINT SPECIAL IN PAVER BLOCK & CHEQUERED TILE

- FLOOR PAINT FOR CHEQUERED TILE

- COLOR COATING FOR PAVER BLOCK

- PAVER BLOCK MACHINERY

- PAVER BLOCK MAKING MACHINE

- PAVING BLOCK MOULDS

- SOUTH SET MOULD

- PRECAST PAVER MOULDS

- SILICONE PAVER MOULDS

- ZIG ZAG PAVER MOULD

- V-SHAPE MOULD

- S-SHAPE MOULD

- PAVER BLOCK FARMA

- STAR MOULD

- PAVING BRICK MOULDS

- TRIHEX MOULD

- NEW HEXAGON MOULD

- PAVER BLOCK MOULD

- SQUARE PAVER MOULDS

- PISTON MOULD

- PAVING BLOCK MOULDS

- PAVER MOULDS

- Cement Concrete Tile Lacquer polish making machine

- PVC MOULDS

- PVC PAVER MOULDS

- Pan Mixer Machine

- Color Pan Mixer Machine

- Heavy Duty Pan Mixer Machine

- Paver Block Pan Mixer Machine

- Interlocking Tile Pan Mixer

- PAN MIXER

- Top Layer Pan Mixer

- Top Color Layer Pan Mixer

- Ring Pan Mixer

- Color Pan Mixer

- Paver Block Pan Mixer

- Pan Mixer Machine

- Pan Mixer Machine For Interlocking Tile

- Ring Pan Mixer Machine

- Top Layer Pan Mixer Machine

- RUBBER MOULDS PAVER

- SUPERPLASTICIZER ADMIXTURE

- TILE HARDENER

- TILE MAKING MACHINE

- VIBRATING TABLE

- Designer Vibro Forming

- Heavy Duty Vibro Forming Table

- Paver Designer Tiles Vibro Forming Table

- Vibrator Machine For Paver Block

- Construction Vibro Forming Machine

- Interlocking Block Vibro Forming Machine

- Designer Tile Vibro Forming Table

- Concrete Block Vibro Forming Table

- Designer Tiles Vibro Forming Table

- Interlocking Tile Vibro Forming Machine

- Paver Block Vibro Forming Machine

- VIBRO FORMING MACHINE

- Construction Vibrating Table

- Interlock Vibrating Machine

- HEAVY DUTY VIBRO FORMING TABLE

- PAVER TILE VIBRATING TABLE

- Paver Block Vibrating Table

- Vibro Forming Machine

- Vibro Forming Table Standard

- Tile Vibro Forming Machine

- Vibrating Table Concrete Moulds

- Vibro Table Paver Block Making Machine

- VIBRATING TABLE FOR CONCRETE

- VIBRO FORMING TABLE

- Contact Us

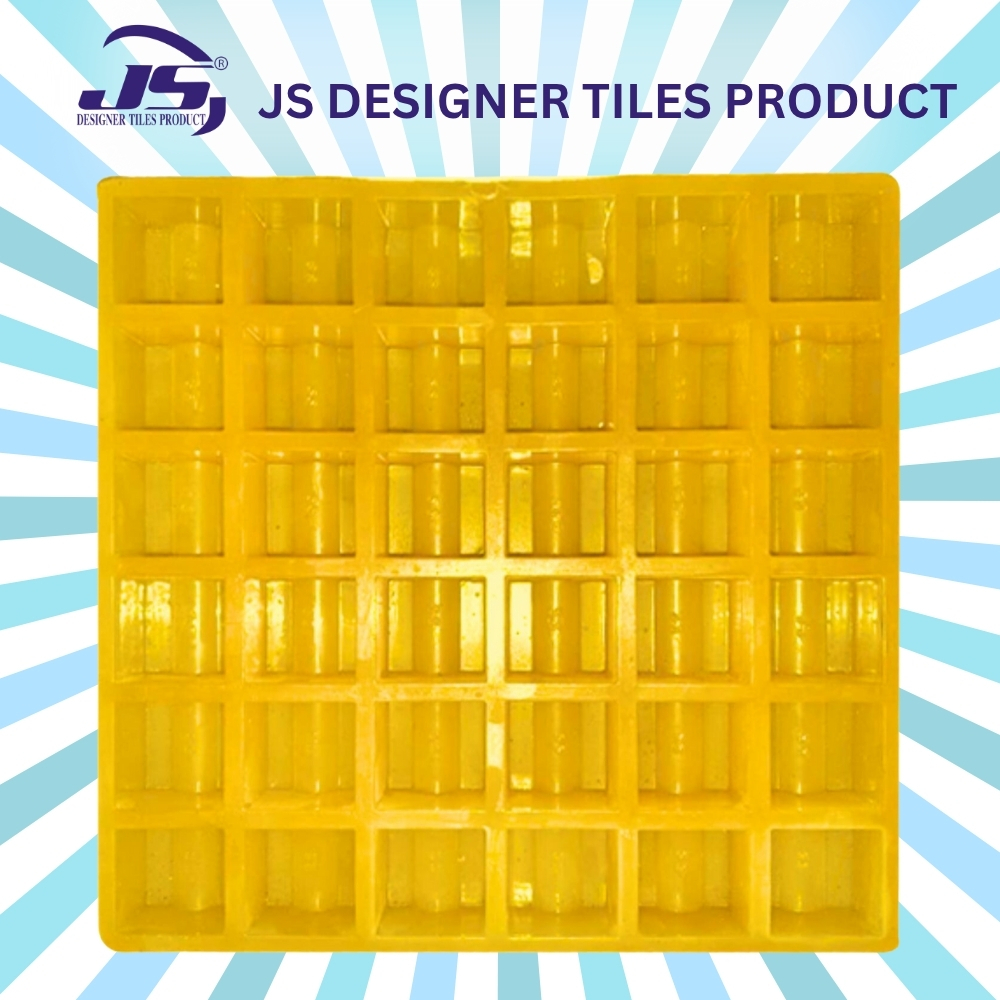

Rcc Cover Block Mould

Price 423 INR/ Piece

MOQ : 25 Kilograms

Rcc Cover Block Mould Specification

- Cavity

- 24

- Molding Material

- SYNTHETIC SILICONE RUBBER

- Material

- Rubber

- Size

- 35.MM

- Product Type

- COVER BLOCK MOULDS

- Mould Weight

- 2.1 Kilograms (kg)

- Mould Life

- 5-6 Years

- Color

- Brown

Rcc Cover Block Mould Trade Information

- Minimum Order Quantity

- 25 Kilograms

- Delivery Time

- Days

- Main Domestic Market

- All India

About Rcc Cover Block Mould

Rcc Cover Block Mouldï

Js Designer Tiles Product Is A Leading Manufacturer Of Synthetic Silicone Plastic Mould, Synthetic Silicone Rubber Mold, Paver Block Making Machine, Spray Lacquer Polish, Sponge Lacquer Polish, Iron Oxide Etc.

Precision Engineering for Construction

This synthetic silicone rubber RCC Cover Block Mould provides 24 cavities for streamlined production, allowing users to manufacture consistent 35 mm cover blocks. Its precision and robust material ensure reliable performance across multiple cycles, making it an essential tool for concrete reinforcement processes.

Long-Lasting and Easy to Handle

Designed to last 56 years, the moulds synthetic silicone rubber composition offers both flexibility and resilience. Weighing only 2.1 kilograms, it is easy to handle and transport, supporting efficient processing on various construction sites.

FAQs of Rcc Cover Block Mould:

Q: How do I use the RCC Cover Block Mould for optimal results?

A: Begin by cleaning the mould and applying a suitable release agent. Pour your prepared concrete mix evenly into each of the 24 cavities, ensuring theyre filled properly. Allow it to set according to the standard curing time before demoulding the cover blocks.Q: What are the benefits of using a synthetic silicone rubber mould?

A: Synthetic silicone rubber ensures flexibility, allowing easy demoulding without damaging the blocks. It also enhances the moulds durability, resulting in a lifespan of 56 years and consistent block production with minimal maintenance.Q: When should I consider replacing the RCC Cover Block Mould?

A: With regular usage and proper care, the mould will typically last between 5 to 6 years. Replace the mould if you notice visible cracks, deformation, or any signs of wear that affect the quality of the produced cover blocks.Q: Where is this mould manufactured and supplied from?

A: This RCC Cover Block Mould is manufactured, exported, and supplied from India, ensuring quality assurance and reliable support for domestic and international buyers.Q: What is the process for cleaning and maintaining the mould?

A: After demoulding the concrete blocks, rinse the mould with water and gently scrub away any residues. Avoid abrasive materials. Store the mould in a shaded area away from direct sunlight to preserve its elasticity.Q: How does using a 24-cavity mould improve production efficiency?

A: With 24 cavities, you can produce multiple cover blocks in a single batch, significantly increasing productivity and ensuring uniformity in block size and strength across all units.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in COVER BLOCK MOULDS Category

Cover Block Rubber Moulds

Price 279 INR / Piece

Minimum Order Quantity : 25 Kilograms

Cavity : 36

Size : 22.MM

Mould Life : 56 Years

Molding Material : SYNTHETIC SILICONE RUBBER

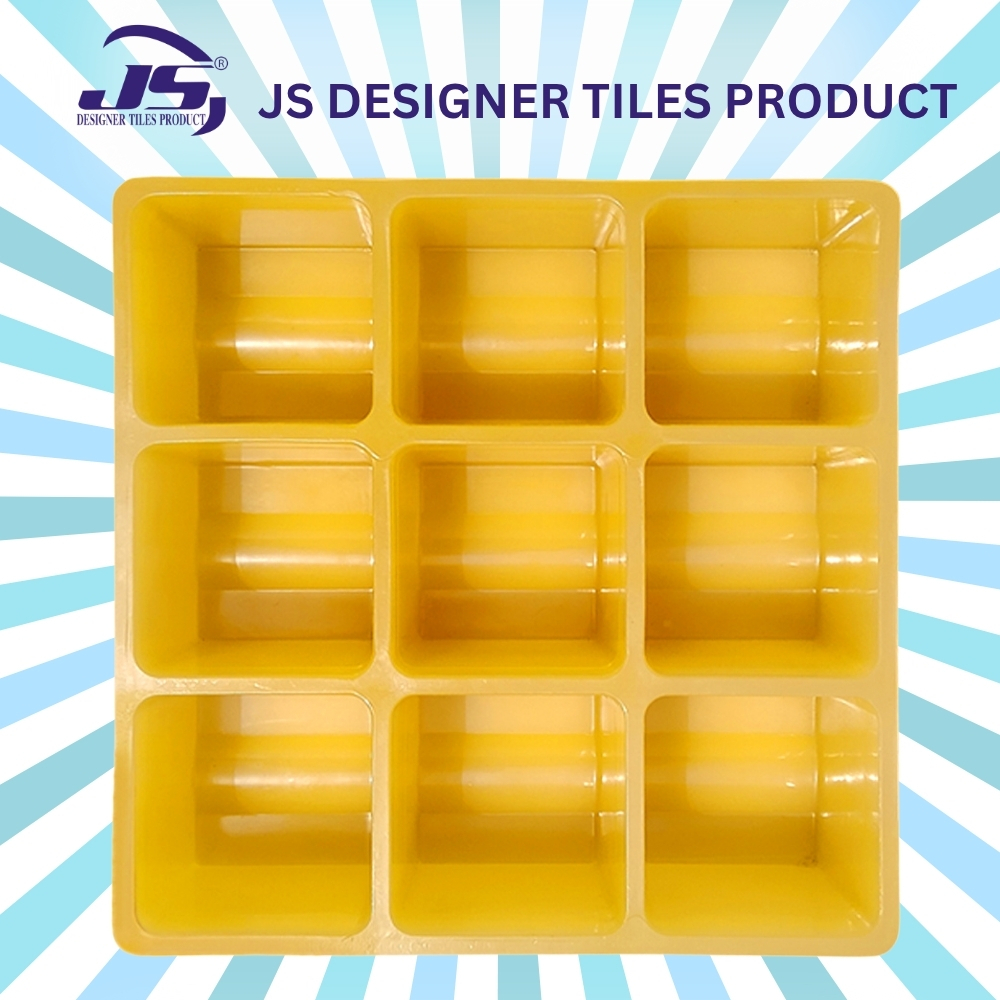

Cover Block Mould Supplier

Price 650 INR / Piece

Minimum Order Quantity : 25 Kilograms

Cavity : 9

Size : 75.MM

Mould Life : 56 Years

Molding Material : SYNTHETIC SILICONE RUBBER

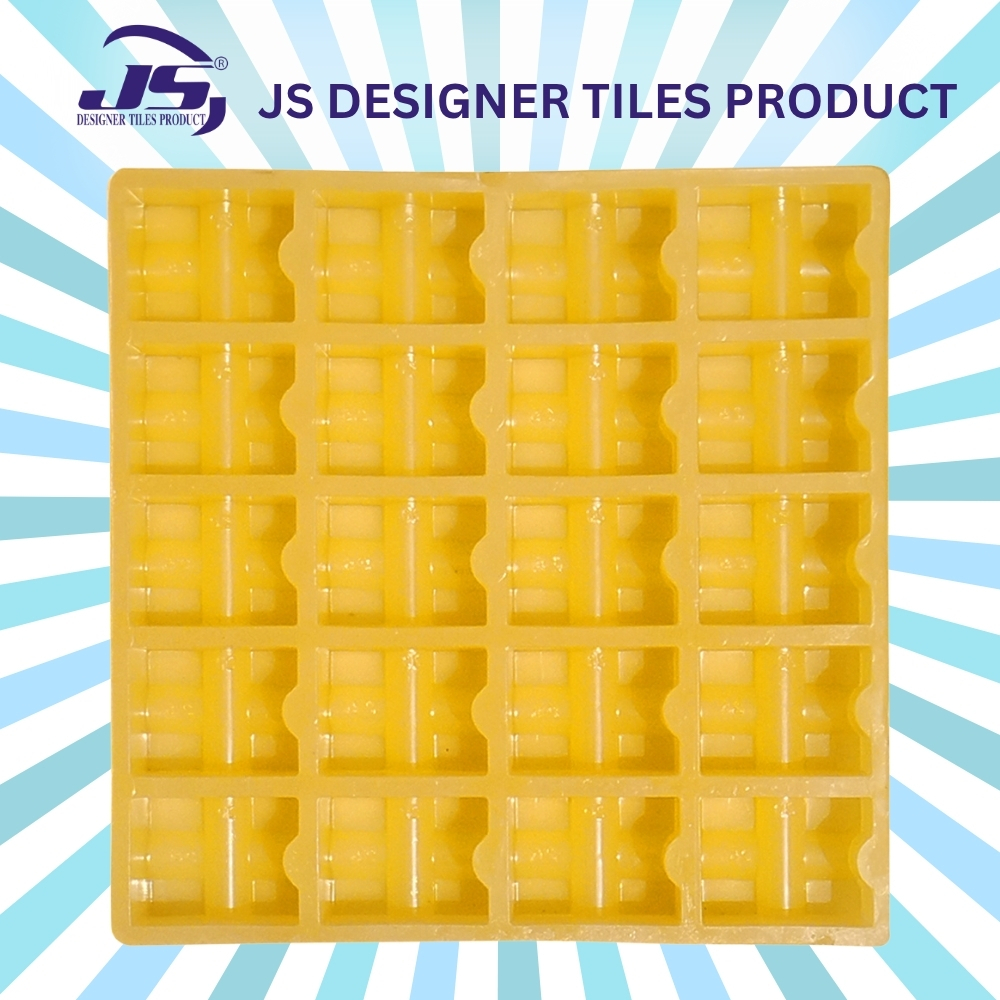

Cover Block Moulds

Price 650 INR / Piece

Minimum Order Quantity : 25 Kilograms

Cavity : 56

Size : 30 & 40.MM

Mould Life : 56 Years

Molding Material : SYNTHETIC SILICONE RUBBER

Round Cover Block Mould

Price 382 INR / Piece

Minimum Order Quantity : 25 Kilograms

Cavity : 5

Size : 40.MM

Mould Life : 56 Years

Molding Material : SYNTHETIC SILICONE RUBBER

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free