- Home Page

- Company Profile

-

Our Products

- CHEMICAL HARDENER

- CHEQUERED TILES MOULD

- COLOR MIXING MACHINE

- CONCRETE BLOCK MOULDS

- HEXAGON KIDA MOULD

- Double Zigzag Mould

- GRASS GRID MOULD

- Milano Paver Block Moulds

- GRASS PAVER MOULD

- L-SHAPE MOULD

- Kaju Katli Paving Block Mould

- MATKA MOULD

- Kida Brooks Mould

- Interlocking Concrete Block Moulds

- Interlocking Paver Moulds

- Mould For Paver Block

- Interlock Block Moulds

- New Damru Mould

- New Cosmic Mould

- CONCRETE CHEMICAL

- CONCRETE HARDENER

- CONCRETE MIXER

- COVER BLOCK MOULDS

- Round Cover Block Mould

- 64 Cavity Pvc Cover Block Mould

- 20,25,30mm 64 Cavity Cover Block Mould

- Multy Cavity Cover Block Mould

- Cover Block Rubber Moulds

- RUBBER COVER BLOCK MOULD

- Square Cover Block Mould

- Concrete Cover Block Moulds

- Cover Block Mould In 20, 25, 40, 50.mm

- 42 Cavity Pvc Cover Block Mould

- Rcc Cover Block Mould

- Cover Block Moulds

- Pvc Cover Block Mould

- Cover Block Moulds Manufacture

- SPACERS RUBBER MOULD

- 49 Cavity Rubber Cover Block Mould

- Cover Block Mould Supplier

- Cover Block Mould 20 & 25.mm

- DESIGNER TILES MOULD

- FLOOR TILES MOULD

- HARDENER MAKING MACHINE

- Paver Block Hardener Making Machine

- Concrete Block Hardener Making Machine

- Hardener Machine

- Interlocking Hardener Machinery

- Interlocking Tile Hardener Making Machine

- Block Hardener Making Machine

- Chemical Hardener Making Machine

- Concrete Hardener Making Machine

- Cover Block Hardener Making Machine

- Designer Tile Hardener Making Machine

- Hardener Making Machine

- Interlocking Block Hardener Making Machine

- Paver Block Clean Mould Releasing Chemical Making Machine

- Paver Chemical Hardener Making Machine

- Paver Hardener Machinery

- Paving Block Hardener Machine

- Rmc Admixtures Chemical Making Machine

- Tile Hardener Chemical Making Machine

- Tile Hardener Making Machine

- CONCRETE ADMIXTURE MAKING MACHINE

- CHEQUERED TILE HARDENER MAKING MACHINE

- INTERLOCKING BLOCK MAKING MACHINE

- INTERLOCKING TILE MAKING MACHINE

- IRON OXIDE PIGMENT

- KERB STONE MOULDS

- LACQUER POLISH MAKING MACHINE

- Interlocking Block Lacquer Polish Making Machine

- Floor Paint And Floor Coat Making Machine

- Paving Block Lacquer Polish Making Machine

- Interlocking Tile Lacquer Polish Making Machine

- Paver Lacquer Making Machine

- Chequered Tiles High Gloss Lacquer Coating Making Machine

- Designer Tile Lacquer Polish Making Machine

- Lacquer Coating Making Machine

- Lacquer Polish Machine

- Lacquer Polish Making Machine

- Lacquer Sealer Making Machine

- Lacquer Shiner Making Machine

- Paver Block High Gloss Lacquer Polish Making Machine

- Paver Block Lacquer Polish Making Machine

- Tile Coating Machine

- Tile Lacquer Polish Making Machine

- Top Coat Lacquer Making Machine

- Water Base Lacquer Coating Making Machine

- Block Lacquer Polish Making Machine

- Water Proofing Coating Making Machine

- MANUAL BLOCK MAKING MACHINE

- PAVER BLOCK DEMOULDING MACHINE

- PAVER BLOCK HARDENER

- PAVER BLOCK LACQUER POLISH

- LACQUER COATING FOR PAVER BLOCKS

- TILE LACQUER POLISH

- HIGH GLOSS LACQUER COATING

- ACRYLIC COATINGS

- ACRYLIC LACQUER

- TOP COAT PAVER BLOCK LACQUER

- PAVER BLOCK SHINER

- TILE POLISH

- LACQUER PAINTS

- LIQUID POLISH FOR PAVING BRICKS

- PAVER BLOCK LACQUER COATING

- WATER PROOFING COATING CHEMICAL

- PAVER SEALER

- PAVER COATING LACQUER

- LACQUER COATING

- PAVER LACQUER

- LACQUER POLISH FOR PAVER BLOCKS

- INTERLOCKING TILES POLISH

- LACQUER POLISH

- PAVER BLOCK LACQUER

- LACQUER COLOR COATING CHEMICAL

- HIGH GLOSS LACQUER POLISH

- INTERLOCKING TILE LACQUER POLISH

- PAVER BLOCK PAINT

- NATURAL LACQUER POLISH

- FLOOR PAINT SPECIAL IN PAVER BLOCK & CHEQUERED TILE

- FLOOR PAINT FOR CHEQUERED TILE

- COLOR COATING FOR PAVER BLOCK

- PAVER BLOCK MACHINERY

- PAVER BLOCK MAKING MACHINE

- PAVING BLOCK MOULDS

- SOUTH SET MOULD

- PRECAST PAVER MOULDS

- SILICONE PAVER MOULDS

- ZIG ZAG PAVER MOULD

- V-SHAPE MOULD

- S-SHAPE MOULD

- PAVER BLOCK FARMA

- STAR MOULD

- PAVING BRICK MOULDS

- TRIHEX MOULD

- NEW HEXAGON MOULD

- PAVER BLOCK MOULD

- SQUARE PAVER MOULDS

- PISTON MOULD

- PAVING BLOCK MOULDS

- PAVER MOULDS

- Cement Concrete Tile Lacquer polish making machine

- PVC MOULDS

- PVC PAVER MOULDS

- Pan Mixer Machine

- Color Pan Mixer Machine

- Heavy Duty Pan Mixer Machine

- Paver Block Pan Mixer Machine

- Interlocking Tile Pan Mixer

- PAN MIXER

- Top Layer Pan Mixer

- Top Color Layer Pan Mixer

- Ring Pan Mixer

- Color Pan Mixer

- Paver Block Pan Mixer

- Pan Mixer Machine

- Pan Mixer Machine For Interlocking Tile

- Ring Pan Mixer Machine

- Top Layer Pan Mixer Machine

- RUBBER MOULDS PAVER

- SUPERPLASTICIZER ADMIXTURE

- TILE HARDENER

- TILE MAKING MACHINE

- VIBRATING TABLE

- Designer Vibro Forming

- Heavy Duty Vibro Forming Table

- Paver Designer Tiles Vibro Forming Table

- Vibrator Machine For Paver Block

- Construction Vibro Forming Machine

- Interlocking Block Vibro Forming Machine

- Designer Tile Vibro Forming Table

- Concrete Block Vibro Forming Table

- Designer Tiles Vibro Forming Table

- Interlocking Tile Vibro Forming Machine

- Paver Block Vibro Forming Machine

- VIBRO FORMING MACHINE

- Construction Vibrating Table

- Interlock Vibrating Machine

- HEAVY DUTY VIBRO FORMING TABLE

- PAVER TILE VIBRATING TABLE

- Paver Block Vibrating Table

- Vibro Forming Machine

- Vibro Forming Table Standard

- Tile Vibro Forming Machine

- Vibrating Table Concrete Moulds

- Vibro Table Paver Block Making Machine

- VIBRATING TABLE FOR CONCRETE

- VIBRO FORMING TABLE

- Contact Us

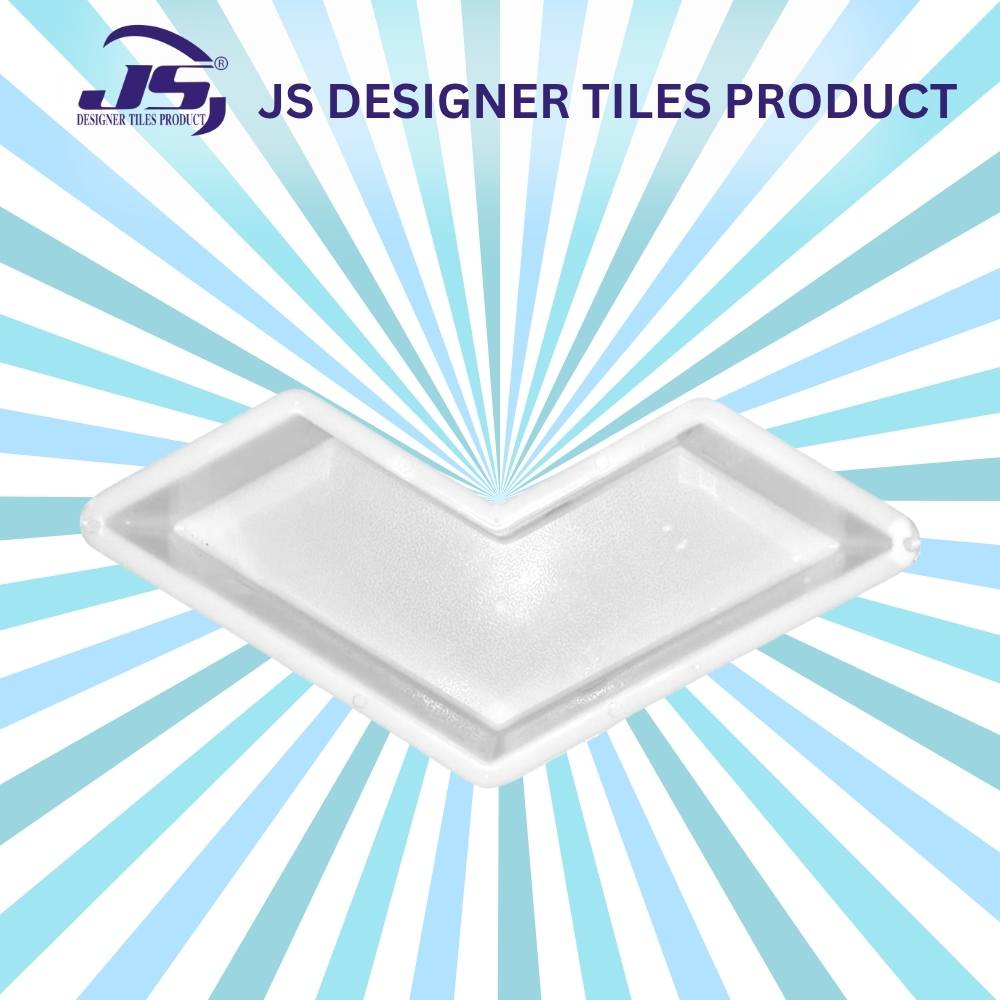

PAVER BLOCK MOULD

Price 43 INR/ Piece

MOQ : 500 Pieces

PAVER BLOCK MOULD Specification

- Molding Material

- SYNTHETIC SILICONE PLASTIC

- Usage

- MAKING PAVER BLOCKS

- Material

- Plastic

- Product Type

- PAVING BLOCK MOULDS

- Mould Life

- 1-2 Years

- Color

- Gray & Red

PAVER BLOCK MOULD Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- Days

- Main Domestic Market

- All India

About PAVER BLOCK MOULD

JS DESIGNER TILES PRODUCT is a leading manufacturer of Synthetic Silicone Plastic Mould, Synthetic Silicone Rubber Mold, Paver Block Making Machine, Spray Lacquer Polish, Sponge Lacquer Polish, Iron Oxide etc.High-Quality Synthetic Silicone Plastic

Each mould is made from premium synthetic silicone plastic, offering exceptional durability and flexibility. This material choice ensures that the mould remains resistant to wear and tear, maintaining the integrity of each paver block produced during its lifetime of 1-2 years.

Vibrant Color Options and Extended Lifespan

With options in both gray and red, these moulds cater to aesthetic and functional requirements. Their robust construction is designed to withstand repeated use, making them a cost-effective solution for businesses focused on efficiency and quality.

Ideal for Indian Exporters, Manufacturers, and Suppliers

Trusted by industry leaders across India, these paver block moulds enable consistent output and reliable performance, supporting large-scale production needs for both domestic and international projects.

FAQs of PAVER BLOCK MOULD:

Q: How are these paver block moulds used in the manufacturing process?

A: The paver block moulds are utilized by pouring concrete or related materials into the synthetic silicone plastic mould. After proper setting, the mould is flexed or tapped to release a perfectly shaped paver block, ensuring minimal waste and best results.Q: What materials are compatible with these paver block moulds?

A: These moulds are designed for use with concrete and similar mixtures used for making paver blocks. Their synthetic silicone plastic construction allows easy demolding without damage to the paver or the mould itself.Q: When should the moulds be replaced for optimal quality?

A: Generally, the moulds are expected to last between 1 to 2 years, depending on the frequency of use and care. Replace the mould when signs of cracking, warping, or diminished flexibility appear to maintain the quality of production.Q: Where are these paver block moulds commonly used?

A: These moulds are widely used across manufacturing facilities in India, serving exporters, suppliers, and construction companies engaged in large-scale paver block production for both domestic and international projects.Q: What is the main benefit of choosing synthetic silicone plastic moulds?

A: Synthetic silicone plastic moulds deliver superior flexibility, durability, and ease of use. They withstand frequent demolding without sticking or breaking, which improves efficiency and reduces production downtime.Q: What colors are available for these paver block moulds?

A: The paver block moulds are available in both gray and red, offering options to suit various design and operational preferences.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PAVING BLOCK MOULDS Category

PRECAST PAVER MOULDS

Price 45 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Plastic

Product Type : PAVING BLOCK MOULDS

Molding Material : SYNTHETIC SILICONE PLASTIC

Usage : MAKING PAVER BLOCKS

S-SHAPE MOULD

Price 41 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Plastic

Product Type : PAVING BLOCK MOULDS

Molding Material : SYNTHETIC SILICONE PLASTIC

Usage : MAKING PAVER BLOCKS

V-SHAPE MOULD

Price 41 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Plastic

Product Type : PAVING BLOCK MOULDS

Molding Material : SYNTHETIC SILICONE PLASTIC

Usage : MAKING PAVER BLOCKS

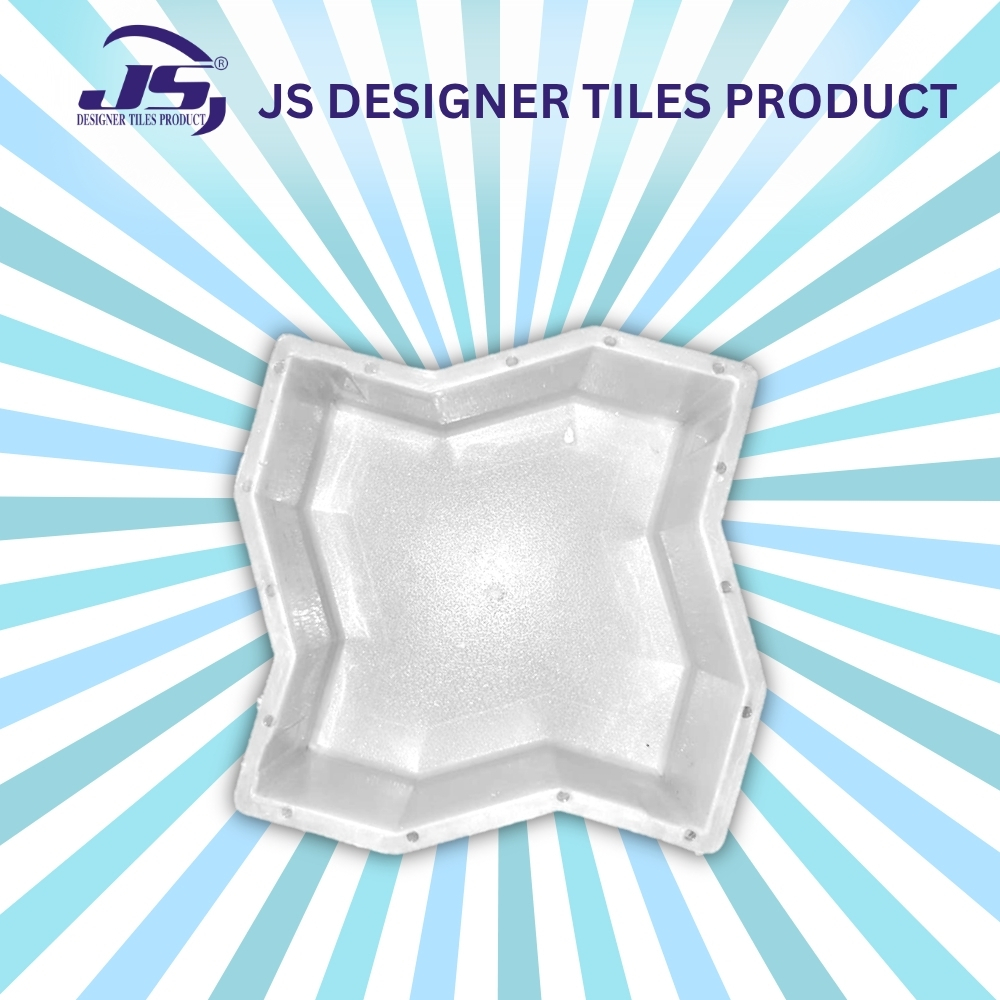

STAR MOULD

Price 50 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Plastic

Product Type : PAVING BLOCK MOULDS

Molding Material : SYNTHETIC SILICONE PLASTIC

Usage : MAKING PAVER BLOCKS

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS