- Home Page

- Company Profile

-

Our Products

- CHEMICAL HARDENER

- CHEQUERED TILES MOULD

- COLOR MIXING MACHINE

- CONCRETE BLOCK MOULDS

- HEXAGON KIDA MOULD

- Kida Brooks Mould

- Mould For Paver Block

- Interlocking Paver Moulds

- Interlock Block Moulds

- Interlocking Concrete Block Moulds

- Double Zigzag Mould

- GRASS GRID MOULD

- Milano Paver Block Moulds

- GRASS PAVER MOULD

- L-SHAPE MOULD

- Kaju Katli Paving Block Mould

- MATKA MOULD

- New Damru Mould

- New Cosmic Mould

- CONCRETE CHEMICAL

- CONCRETE HARDENER

- CONCRETE MIXER

- COVER BLOCK MOULDS

- SPACERS RUBBER MOULD

- Concrete Cover Block Moulds

- Cover Block Moulds Manufacture

- Cover Block Mould In 20, 25, 40, 50.mm

- Cover Block Mould 20 & 25.mm

- 42 Cavity Pvc Cover Block Mould

- 20,25,30mm 64 Cavity Cover Block Mould

- Multy Cavity Cover Block Mould

- Cover Block Rubber Moulds

- RUBBER COVER BLOCK MOULD

- 49 Cavity Rubber Cover Block Mould

- Rcc Cover Block Mould

- Round Cover Block Mould

- Square Cover Block Mould

- Cover Block Mould Supplier

- Pvc Cover Block Mould

- 64 Cavity Pvc Cover Block Mould

- Cover Block Moulds

- DESIGNER TILES MOULD

- FLOOR TILES MOULD

- HARDENER MAKING MACHINE

- Paver Block Hardener Making Machine

- Concrete Block Hardener Making Machine

- Hardener Machine

- Interlocking Hardener Machinery

- Interlocking Tile Hardener Making Machine

- Block Hardener Making Machine

- Chemical Hardener Making Machine

- Concrete Hardener Making Machine

- Cover Block Hardener Making Machine

- Designer Tile Hardener Making Machine

- Hardener Making Machine

- Interlocking Block Hardener Making Machine

- Paver Block Clean Mould Releasing Chemical Making Machine

- Paver Chemical Hardener Making Machine

- Paver Hardener Machinery

- Paving Block Hardener Machine

- Rmc Admixtures Chemical Making Machine

- Tile Hardener Chemical Making Machine

- Tile Hardener Making Machine

- CONCRETE ADMIXTURE MAKING MACHINE

- CHEQUERED TILE HARDENER MAKING MACHINE

- INTERLOCKING BLOCK MAKING MACHINE

- INTERLOCKING TILE MAKING MACHINE

- IRON OXIDE PIGMENT

- KERB STONE MOULDS

- LACQUER POLISH MAKING MACHINE

- Interlocking Block Lacquer Polish Making Machine

- Floor Paint And Floor Coat Making Machine

- Paving Block Lacquer Polish Making Machine

- Interlocking Tile Lacquer Polish Making Machine

- Paver Lacquer Making Machine

- Chequered Tiles High Gloss Lacquer Coating Making Machine

- Designer Tile Lacquer Polish Making Machine

- Lacquer Coating Making Machine

- Lacquer Polish Machine

- Lacquer Polish Making Machine

- Lacquer Sealer Making Machine

- Lacquer Shiner Making Machine

- Paver Block High Gloss Lacquer Polish Making Machine

- Paver Block Lacquer Polish Making Machine

- Tile Coating Machine

- Tile Lacquer Polish Making Machine

- Top Coat Lacquer Making Machine

- Water Base Lacquer Coating Making Machine

- Block Lacquer Polish Making Machine

- Water Proofing Coating Making Machine

- MANUAL BLOCK MAKING MACHINE

- PAVER BLOCK DEMOULDING MACHINE

- PAVER BLOCK HARDENER

- PAVER BLOCK LACQUER POLISH

- LACQUER COATING FOR PAVER BLOCKS

- HIGH GLOSS LACQUER COATING

- ACRYLIC COATINGS

- TILE LACQUER POLISH

- PAVER BLOCK SHINER

- TOP COAT PAVER BLOCK LACQUER

- ACRYLIC LACQUER

- LIQUID POLISH FOR PAVING BRICKS

- TILE POLISH

- LACQUER PAINTS

- WATER PROOFING COATING CHEMICAL

- PAVER SEALER

- PAVER BLOCK LACQUER COATING

- PAVER COATING LACQUER

- LACQUER COATING

- PAVER LACQUER

- LACQUER POLISH FOR PAVER BLOCKS

- INTERLOCKING TILES POLISH

- LACQUER POLISH

- PAVER BLOCK LACQUER

- LACQUER COLOR COATING CHEMICAL

- HIGH GLOSS LACQUER POLISH

- INTERLOCKING TILE LACQUER POLISH

- PAVER BLOCK PAINT

- NATURAL LACQUER POLISH

- FLOOR PAINT SPECIAL IN PAVER BLOCK & CHEQUERED TILE

- FLOOR PAINT FOR CHEQUERED TILE

- COLOR COATING FOR PAVER BLOCK

- PAVER BLOCK MACHINERY

- PAVER BLOCK MAKING MACHINE

- PAVING BLOCK MOULDS

- ZIG ZAG PAVER MOULD

- V-SHAPE MOULD

- S-SHAPE MOULD

- PAVER BLOCK MOULD

- PAVER BLOCK FARMA

- STAR MOULD

- TRIHEX MOULD

- SQUARE PAVER MOULDS

- SOUTH SET MOULD

- SILICONE PAVER MOULDS

- PRECAST PAVER MOULDS

- NEW HEXAGON MOULD

- PISTON MOULD

- PAVER MOULDS

- PAVING BRICK MOULDS

- PAVING BLOCK MOULDS

- Cement Concrete Tile Lacquer polish making machine

- PVC MOULDS

- PVC PAVER MOULDS

- Pan Mixer Machine

- Paver Block Pan Mixer Machine

- Color Pan Mixer Machine

- Heavy Duty Pan Mixer Machine

- Interlocking Tile Pan Mixer

- PAN MIXER

- Top Layer Pan Mixer

- Top Color Layer Pan Mixer

- Ring Pan Mixer

- Color Pan Mixer

- Paver Block Pan Mixer

- Pan Mixer Machine

- Pan Mixer Machine For Interlocking Tile

- Ring Pan Mixer Machine

- Top Layer Pan Mixer Machine

- RUBBER MOULDS PAVER

- SUPERPLASTICIZER ADMIXTURE

- TILE HARDENER

- TILE MAKING MACHINE

- VIBRATING TABLE

- Designer Vibro Forming

- Construction Vibro Forming Machine

- Designer Tile Vibro Forming Table

- Vibrator Machine For Paver Block

- Interlocking Block Vibro Forming Machine

- Heavy Duty Vibro Forming Table

- Paver Designer Tiles Vibro Forming Table

- Concrete Block Vibro Forming Table

- Designer Tiles Vibro Forming Table

- Interlocking Tile Vibro Forming Machine

- Paver Block Vibro Forming Machine

- VIBRO FORMING MACHINE

- PAVER TILE VIBRATING TABLE

- Construction Vibrating Table

- Interlock Vibrating Machine

- HEAVY DUTY VIBRO FORMING TABLE

- Paver Block Vibrating Table

- Vibro Forming Machine

- Vibro Forming Table Standard

- Tile Vibro Forming Machine

- Vibrating Table Concrete Moulds

- Vibro Table Paver Block Making Machine

- VIBRATING TABLE FOR CONCRETE

- VIBRO FORMING TABLE

- Contact Us

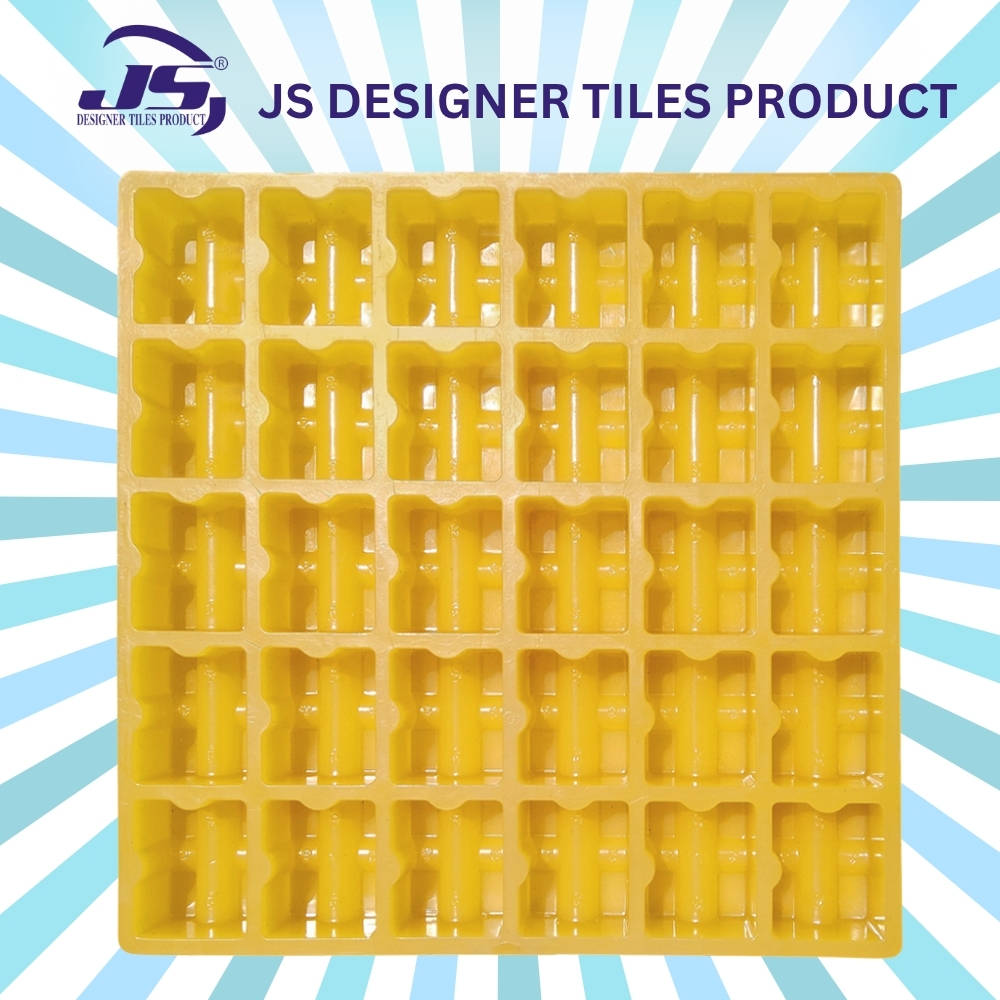

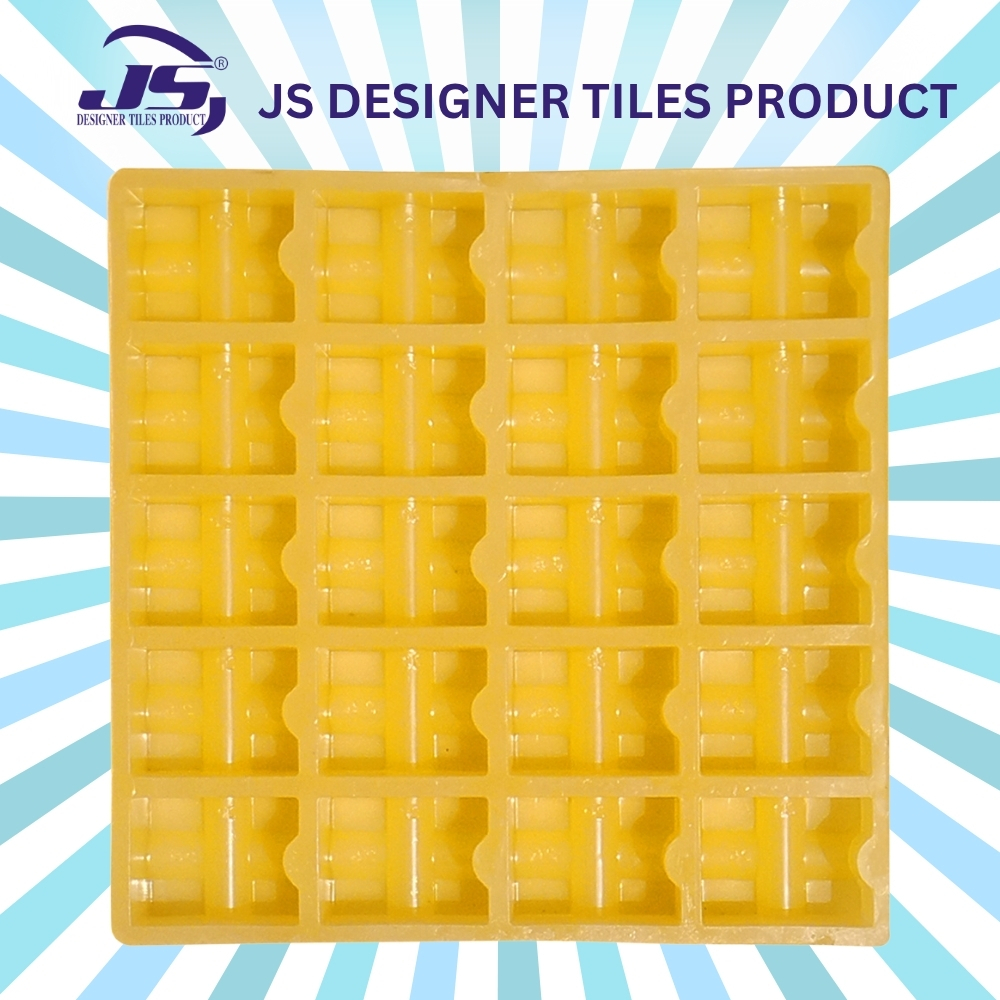

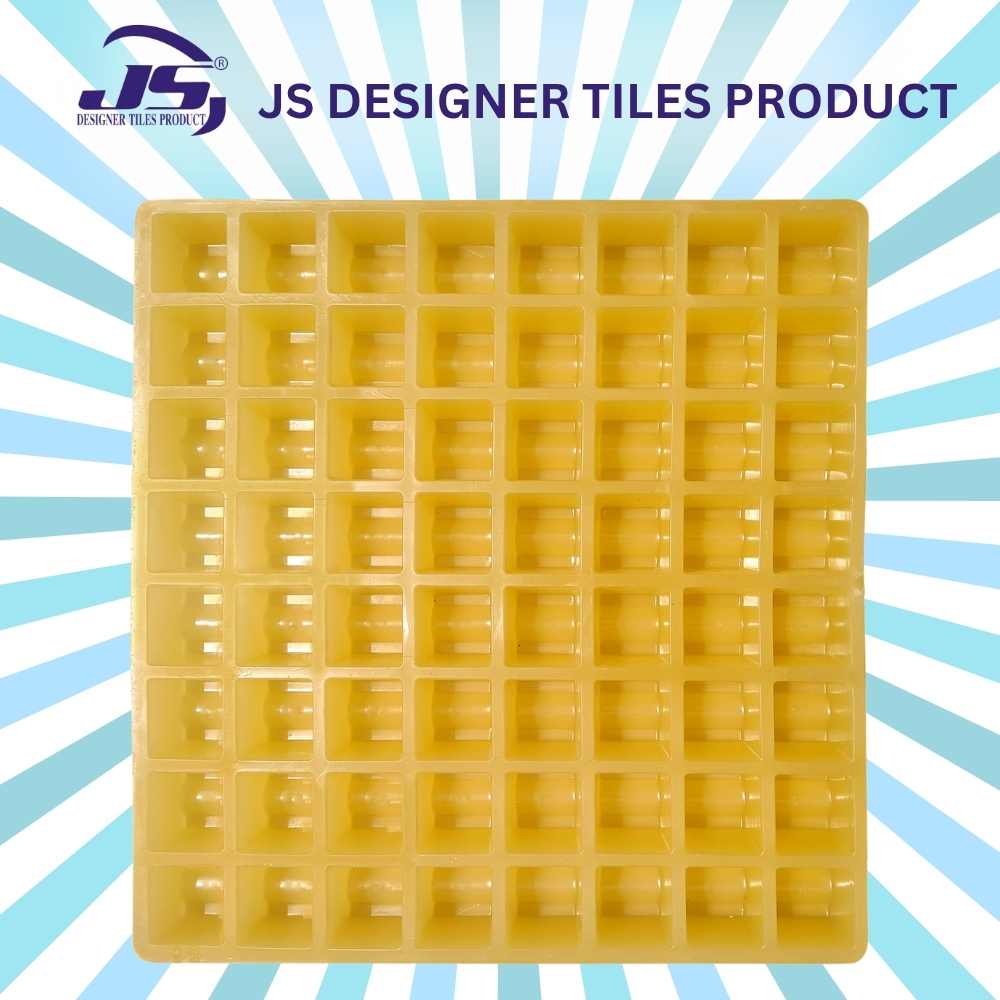

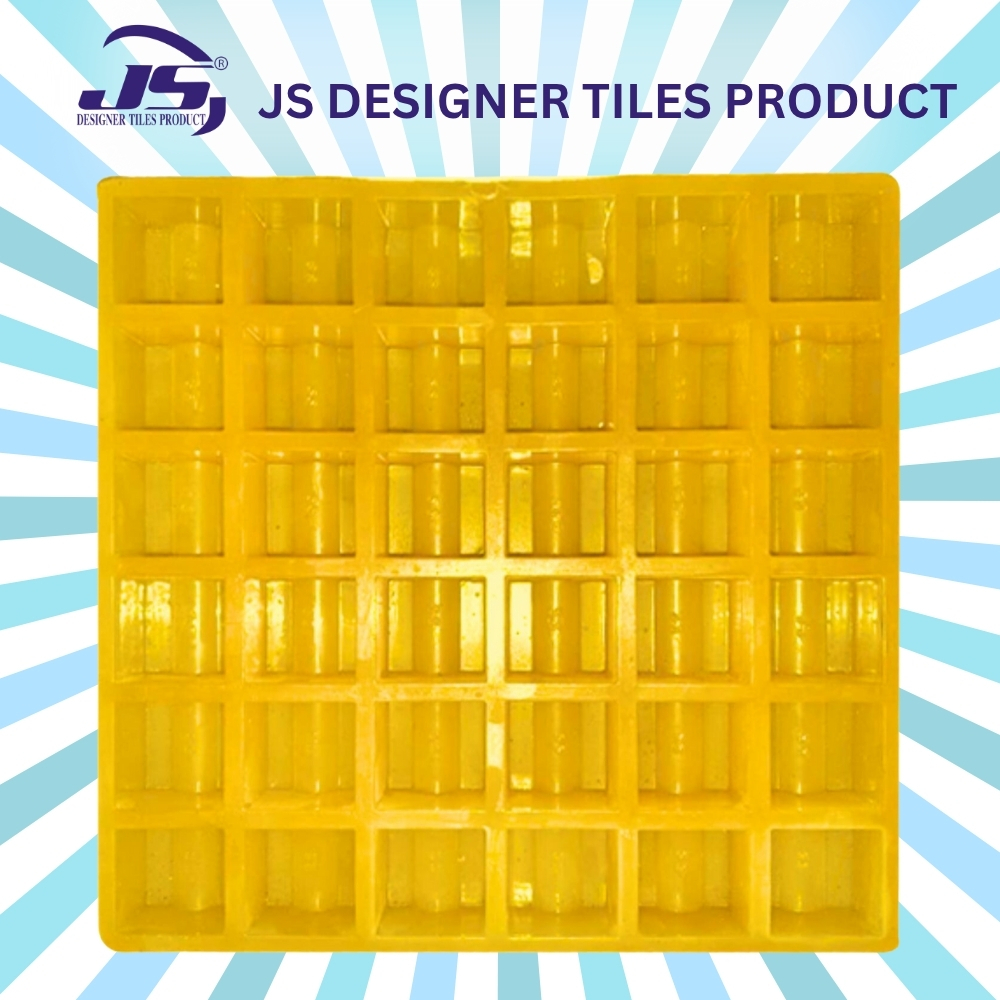

Multy Cavity Cover Block Mould

Price 206 INR/ Piece

MOQ : 25 Kilograms

Multy Cavity Cover Block Mould Specification

- Cavity

- 30

- Molding Material

- SYNTHETIC SILICONE RUBBER

- Size

- 20, 25, 40 & 50.MM

- Product Type

- COVER BLOCK MOULDS

- Mould Weight

- 2.5 Kilograms (kg)

- Mould Life

- 5-6 Years

Multy Cavity Cover Block Mould Trade Information

- Minimum Order Quantity

- 25 Kilograms

- Delivery Time

- Days

- Main Domestic Market

- All India

About Multy Cavity Cover Block Mould

Multy Cavity Cover Block Mouldï

Js Designer Tiles Product Is A Leading Manufacturer Of Synthetic Silicone Plastic Mould, Synthetic Silicone Rubber Mold, Paver Block Making Machine, Spray Lacquer Polish, Sponge Lacquer Polish, Iron Oxide Etc.

Advanced Material for Longevity

Constructed from synthetic silicone rubber, this mould resists abrasion and deformation even during continuous use. Its exceptional flexibility and toughness support repeated demoulding and prolonged operational life, making it a reliable asset in any production setup.

Versatile Size Options

To meet diverse project needs, the mould features cavities for sizes 20 mm, 25 mm, 40 mm, and 50 mm. This adaptability simplifies inventory management and streamlines your cover block production process, supporting a variety of construction standards.

Trusted Exporter and Manufacturer

With a strong presence in India, we serve a broad customer base across domestic and international markets. Strict quality control and robust after-sales support underscore our commitment to delivering dependable, high-performance mould solutions.

FAQs of Multy Cavity Cover Block Mould:

Q: How should the Multy Cavity Cover Block Mould be used for optimal results?

A: For optimal results, clean the mould thoroughly before and after each use. Pour the molding material evenly into each cavity, ensuring complete coverage. Allow adequate curing time before demoulding to maintain precise shape and finish.Q: What makes synthetic silicone rubber suitable for this mould?

A: Synthetic silicone rubber provides excellent flexibility, heat resistance, and a non-stick surface, allowing for easy demoulding and a long service life. This material withstands frequent usage without compromising the moulds integrity.Q: When is it advisable to replace the mould?

A: We recommend replacing the mould after 5 to 6 years of regular use or if you observe significant wear, cracking, or deformation that could affect the accuracy of your cover blocks.Q: Where is the Multy Cavity Cover Block Mould manufactured and supplied from?

A: The mould is designed, manufactured, and supplied from our facilities in India. As a reliable exporter and manufacturer, we cater to customers across India and globally.Q: What is the process for ordering custom sizes or bulk quantities?

A: To order custom sizes or bulk quantities, contact our sales team directly. We accommodate specific requirements and will assist you with customization and large-volume orders efficiently.Q: What benefits does a 30-cavity design provide?

A: The 30-cavity design increases productivity by enabling the simultaneous casting of multiple cover blocks. This helps save time, reduces labor costs, and supports large-scale construction projects.Q: How does mould weight impact usability?

A: At 2.5 kilograms, the mould strikes a balance between robustness and ease of handling, making it manageable for operators and suitable for frequent repositioning on production lines.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in COVER BLOCK MOULDS Category

Cover Block Moulds

Price 650 INR / Piece

Minimum Order Quantity : 25 Kilograms

Molding Material : SYNTHETIC SILICONE RUBBER

Cavity : 56

Mould Life : 56 Years

Size : 30 & 40.MM

64 Cavity Pvc Cover Block Mould

Price 650 INR / Piece

Minimum Order Quantity : 25 Kilograms

Molding Material : SYNTHETIC SILICONE RUBBER

Cavity : 64

Mould Life : 56 Years

Size : 20.MM

Cover Block Rubber Moulds

Price 279 INR / Piece

Minimum Order Quantity : 25 Kilograms

Molding Material : SYNTHETIC SILICONE RUBBER

Cavity : 36

Mould Life : 56 Years

Size : 22.MM

SPACERS RUBBER MOULD

Price 402 INR / Piece

Minimum Order Quantity : 25 Kilograms

Molding Material : SYNTHETIC SILICONE RUBBER

Cavity : 16

Mould Life : 56 Years

Size : 40, 50 & 60.MM

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free