- Home Page

- Company Profile

-

Our Products

- CHEMICAL HARDENER

- CHEQUERED TILES MOULD

- COLOR MIXING MACHINE

- CONCRETE BLOCK MOULDS

- HEXAGON KIDA MOULD

- Double Zigzag Mould

- GRASS GRID MOULD

- Milano Paver Block Moulds

- GRASS PAVER MOULD

- L-SHAPE MOULD

- Kaju Katli Paving Block Mould

- MATKA MOULD

- Kida Brooks Mould

- Interlocking Concrete Block Moulds

- Interlocking Paver Moulds

- Mould For Paver Block

- Interlock Block Moulds

- New Damru Mould

- New Cosmic Mould

- CONCRETE CHEMICAL

- CONCRETE HARDENER

- CONCRETE MIXER

- COVER BLOCK MOULDS

- Round Cover Block Mould

- 64 Cavity Pvc Cover Block Mould

- 20,25,30mm 64 Cavity Cover Block Mould

- Multy Cavity Cover Block Mould

- Cover Block Rubber Moulds

- RUBBER COVER BLOCK MOULD

- Square Cover Block Mould

- Concrete Cover Block Moulds

- Cover Block Mould In 20, 25, 40, 50.mm

- 42 Cavity Pvc Cover Block Mould

- Cover Block Moulds

- Pvc Cover Block Mould

- Cover Block Moulds Manufacture

- SPACERS RUBBER MOULD

- 49 Cavity Rubber Cover Block Mould

- Cover Block Mould Supplier

- Cover Block Mould 20 & 25.mm

- Rcc Cover Block Mould

- DESIGNER TILES MOULD

- FLOOR TILES MOULD

- HARDENER MAKING MACHINE

- Paver Block Hardener Making Machine

- Concrete Block Hardener Making Machine

- Hardener Machine

- Interlocking Hardener Machinery

- Interlocking Tile Hardener Making Machine

- Block Hardener Making Machine

- Chemical Hardener Making Machine

- Concrete Hardener Making Machine

- Cover Block Hardener Making Machine

- Designer Tile Hardener Making Machine

- Hardener Making Machine

- Interlocking Block Hardener Making Machine

- Paver Block Clean Mould Releasing Chemical Making Machine

- Paver Chemical Hardener Making Machine

- Paver Hardener Machinery

- Paving Block Hardener Machine

- Rmc Admixtures Chemical Making Machine

- Tile Hardener Chemical Making Machine

- Tile Hardener Making Machine

- CONCRETE ADMIXTURE MAKING MACHINE

- CHEQUERED TILE HARDENER MAKING MACHINE

- INTERLOCKING BLOCK MAKING MACHINE

- INTERLOCKING TILE MAKING MACHINE

- IRON OXIDE PIGMENT

- KERB STONE MOULDS

- LACQUER POLISH MAKING MACHINE

- Interlocking Block Lacquer Polish Making Machine

- Floor Paint And Floor Coat Making Machine

- Paving Block Lacquer Polish Making Machine

- Interlocking Tile Lacquer Polish Making Machine

- Paver Lacquer Making Machine

- Chequered Tiles High Gloss Lacquer Coating Making Machine

- Designer Tile Lacquer Polish Making Machine

- Lacquer Coating Making Machine

- Lacquer Polish Machine

- Lacquer Polish Making Machine

- Lacquer Sealer Making Machine

- Lacquer Shiner Making Machine

- Paver Block High Gloss Lacquer Polish Making Machine

- Paver Block Lacquer Polish Making Machine

- Tile Coating Machine

- Tile Lacquer Polish Making Machine

- Top Coat Lacquer Making Machine

- Water Base Lacquer Coating Making Machine

- Block Lacquer Polish Making Machine

- Water Proofing Coating Making Machine

- MANUAL BLOCK MAKING MACHINE

- PAVER BLOCK DEMOULDING MACHINE

- PAVER BLOCK HARDENER

- PAVER BLOCK LACQUER POLISH

- ACRYLIC COATINGS

- TILE LACQUER POLISH

- HIGH GLOSS LACQUER COATING

- LACQUER COATING FOR PAVER BLOCKS

- PAVER BLOCK SHINER

- TOP COAT PAVER BLOCK LACQUER

- ACRYLIC LACQUER

- TILE POLISH

- LACQUER PAINTS

- LIQUID POLISH FOR PAVING BRICKS

- PAVER SEALER

- PAVER BLOCK LACQUER COATING

- WATER PROOFING COATING CHEMICAL

- PAVER COATING LACQUER

- LACQUER COATING

- PAVER LACQUER

- LACQUER POLISH FOR PAVER BLOCKS

- INTERLOCKING TILES POLISH

- LACQUER POLISH

- LACQUER COLOR COATING CHEMICAL

- PAVER BLOCK LACQUER

- HIGH GLOSS LACQUER POLISH

- INTERLOCKING TILE LACQUER POLISH

- PAVER BLOCK PAINT

- NATURAL LACQUER POLISH

- FLOOR PAINT SPECIAL IN PAVER BLOCK & CHEQUERED TILE

- FLOOR PAINT FOR CHEQUERED TILE

- COLOR COATING FOR PAVER BLOCK

- PAVER BLOCK MACHINERY

- PAVER BLOCK MAKING MACHINE

- PAVING BLOCK MOULDS

- PRECAST PAVER MOULDS

- SILICONE PAVER MOULDS

- ZIG ZAG PAVER MOULD

- V-SHAPE MOULD

- S-SHAPE MOULD

- PAVER BLOCK FARMA

- STAR MOULD

- PAVING BRICK MOULDS

- TRIHEX MOULD

- NEW HEXAGON MOULD

- PAVER BLOCK MOULD

- SQUARE PAVER MOULDS

- PISTON MOULD

- PAVING BLOCK MOULDS

- PAVER MOULDS

- SOUTH SET MOULD

- Cement Concrete Tile Lacquer polish making machine

- PVC MOULDS

- PVC PAVER MOULDS

- Pan Mixer Machine

- Paver Block Pan Mixer Machine

- Heavy Duty Pan Mixer Machine

- Color Pan Mixer Machine

- Interlocking Tile Pan Mixer

- PAN MIXER

- Top Layer Pan Mixer

- Top Color Layer Pan Mixer

- Ring Pan Mixer

- Color Pan Mixer

- Paver Block Pan Mixer

- Pan Mixer Machine

- Pan Mixer Machine For Interlocking Tile

- Ring Pan Mixer Machine

- Top Layer Pan Mixer Machine

- RUBBER MOULDS PAVER

- SUPERPLASTICIZER ADMIXTURE

- TILE HARDENER

- TILE MAKING MACHINE

- VIBRATING TABLE

- Designer Vibro Forming

- Heavy Duty Vibro Forming Table

- Paver Designer Tiles Vibro Forming Table

- Vibrator Machine For Paver Block

- Construction Vibro Forming Machine

- Interlocking Block Vibro Forming Machine

- Designer Tile Vibro Forming Table

- Concrete Block Vibro Forming Table

- Designer Tiles Vibro Forming Table

- Interlocking Tile Vibro Forming Machine

- Paver Block Vibro Forming Machine

- VIBRO FORMING MACHINE

- Construction Vibrating Table

- Interlock Vibrating Machine

- HEAVY DUTY VIBRO FORMING TABLE

- PAVER TILE VIBRATING TABLE

- Paver Block Vibrating Table

- Vibro Forming Machine

- Vibro Forming Table Standard

- Tile Vibro Forming Machine

- Vibrating Table Concrete Moulds

- Vibro Table Paver Block Making Machine

- VIBRATING TABLE FOR CONCRETE

- VIBRO FORMING TABLE

- Contact Us

Concrete Paver Block Machine

Price 160000 INR/ Piece

MOQ : 1 Piece

Concrete Paver Block Machine Specification

- Product Type

- PAVER BLOCK MAKING MACHINE

- General Use

- Industrial

- Power

- 2 HP 3 PHASE Horsepower (HP)

- Voltage

- 220-240 Volt (v)

- Warranty

- 1 YEAR

- Color

- Multicolour

Concrete Paver Block Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 4-5 Days

- Main Domestic Market

- All India

About Concrete Paver Block Machine

Concrete Paver Block Machine

Js Designer Tiles Product Is A Leading Manufacturer Of Synthetic Silicone Plastic Mould, Synthetic Silicone Rubber Mold, Paver Block Making Machine, Spray Lacquer Polish, Sponge Lacquer Polish, Iron Oxide Etc.

Reliable Power and Performance

Equipped with a 2 HP 3-phase motor, this machine provides stable and powerful performance suitable for industrial-scale production. Its adaptability to standard 220-240 Volt power supply meets the requirements of most commercial settings, allowing for uninterrupted operations.

Versatility for Industrial Applications

Engineered for general industrial use, this paver block machine meets the diverse demands of construction and infrastructure. Its multicolour design and robust build enable consistent output, making it an ideal choice for suppliers, manufacturers, and exporters across India.

Comprehensive Warranty and Support

This machine includes a 1-year warranty, reflecting the manufacturers confidence in its durability and performance. Customers benefit from after-sales support, minimizing downtime and ensuring smooth operation throughout the warranty period.

FAQs of Concrete Paver Block Machine:

Q: How does the 2 HP 3-phase motor enhance the production of paver blocks?

A: The 2 HP 3-phase motor provides reliable and continuous power, enabling efficient and consistent molding and compaction of concrete for high-quality paver block production even in demanding industrial environments.Q: What is the process for operating the Concrete Paver Block Machine?

A: The machine is easy to operate: feed raw materials such as cement, sand, and aggregates into the hopper, set the operational parameters, and initiate the process. The machine will then mold and compact the mixture into paver blocks, ready for curing.Q: When should regular maintenance be performed on this machine?

A: It is advisable to follow a routine maintenance schedule, which typically involves checking the mechanical and electrical components once a week, lubricating moving parts regularly, and inspecting for wear and tear to ensure optimal performance.Q: Where can this machine be installed for best efficiency?

A: For maximum efficiency, it should be installed in a well-ventilated industrial facility with access to stable 220-240 Volt power supply and sufficient space for handling raw materials and finished blocks.Q: What are the primary benefits of using this machine for industrial applications?

A: This machine delivers productivity, uniform block quality, and reduced labor costs. The 1-year warranty and robust service support add further value, making it a reliable asset for any concrete paver block manufacturing operation.Q: How is this machine suitable for exporters, manufacturers, and suppliers in India?

A: Its compliance with industrial standards, efficient output, and adaptability to common electrical systems in India make it a preferred choice for exporters, manufacturers, and suppliers looking for reliable paver block production solutions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PAVER BLOCK MAKING MACHINE Category

PAVING BLOCK MAKING MACHINE

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220240 Volt (v)

Warranty : 1 YEAR

Color : Multicolour

General Use : Industrial

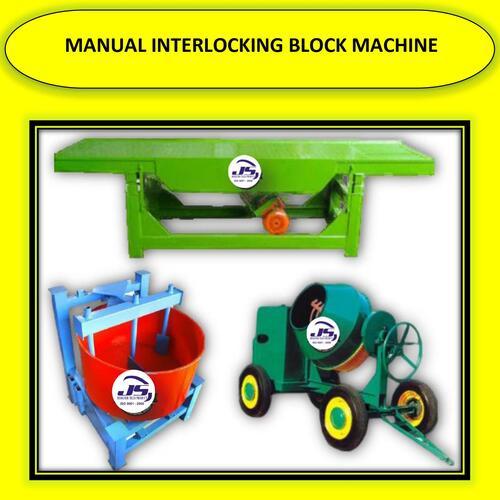

Manual Interlocking Block Machine

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220240 Volt (v)

Warranty : 1 YEAR

Color : Multicolour

General Use : Industrial

Industrial Paver Block Plant

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220240 Volt (v)

Warranty : 1 YEAR

Color : Blue

General Use : Industrial

PAVEMENT BLOCK MAKING MACHINE

Price 160000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220240 Volt (v)

Warranty : 1 YEAR

Color : Multicolour

General Use : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS